60

A

English

⋅

Nautilus

®

T

en

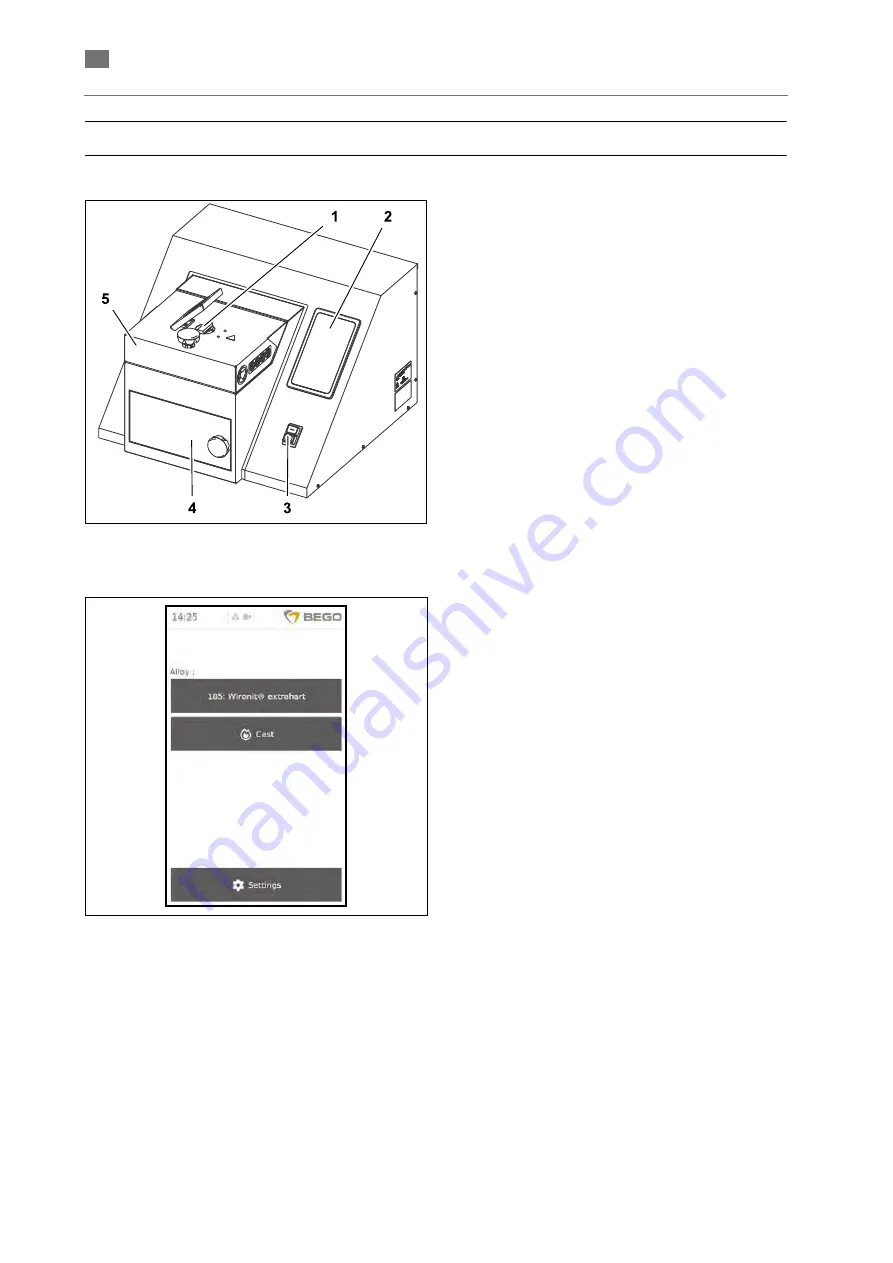

Device description

NAUTILUS

®

T does not come with a pyrometer and

thus no temperature measurement. The casting

process must be carried out manually while

observing the melt. Casting and diagnostic

protocols without a specification of the casting

temperature are not conclusive and, thus, not

possible. However, the device can be updated with

the aid of a USB flash drive (not included in scope of

delivery).

1

Camera

2

Touchscreen

3

Main switch

4

Mould door

5

Crucible door

Overview

After the device has been switched on, the following

functions can be called up via the touchscreen:

Casting

"Casting" can be started once the alloy has been

selected.

Settings

This is where, for instance, new program locations

for non-BEGO alloys are set up.

Summary of Contents for Nautilus CC plus

Page 7: ...English Nautilus CC plus Nautilus T 7 86105 BA en 00 en Unpacking Packing REF 17909 ...

Page 42: ...42 86105 BA en 00 English Nautilus CC plus Nautilus T en ...

Page 43: ...Nautilus CC plus en English ...

Page 59: ...Nautilus T en English ...

Page 83: ...English Nautilus CC plus Nautilus T 83 86105 BA en 00 en NAUTILUS T ...

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......