• PROLONGED EXPOSURE TO LOUD NOISE MAY

CAUSE PERMANENT HEARING LOSS! Tractors

with or without tillers attached can often create

enough noise to cause permanent hearing loss.

We recommend that you use hearing protection if

the noise in the operator’s position exceeds 80db.

Long-term exposure to noise levels over 90db

adjacent to the operator may cause permanent total

hearing loss. NOTE: Hearing loss from loud noises

is cumulative over a lifetime, with no chance of

natural recovery.

• Always wear your seat belt. Serious injury or

even death could result from falling off the tractor

- particularly during a rollover when the operator

could be trapped under the ROPS or the tractor.

• Operate only in daylight or good artificial light.

• Ensure tiller is properly mounted, adjusted and in

good operating condition.

• Ensure that all safety guards and safety decals

are properly installed and in good condition.

• Do not operate unless all personnel, livestock,

and pets are at least 100’ away to prevent injury by

thrown objects.

• Never operate tractor and Tiller under trees with

low hanging limbs. Operators can be knocked off

the tractor and then run over by the tiller.

• The rotating parts of this machine have been

designed and tested for rugged use. However, they

could fail upon impact with heavy, solid objects

such as steel guardrails, concrete abutments,

and tree stumps. Such an impact could cause

broken objects to be thrown outward at very high

velocities. To reduce the possibility of property

damage, serious injury, or even death, never allow

the tines to come in contact with such objects.

• Stop tiller and tractor immediately upon striking

an obstruction. Turn engine off, remove key, then

inspect and repair any damage before resuming.

• Stay alert for uneven terrain and holes. Remove

all rocks, roots, posts and other hazards. Keep

away from drop-offs and hazards that could cause

rollover. Use extreme care and maintain minimum

ground speed when transporting or operating on

hillsides, close to ditches or fences or over rough

ground. Be careful and slow down when turning

sharp corners and changing direction on slopes.

Do not start or stop suddenly on slopes and avoid

operating on steep slopes. In extremely uneven

terrain, rear wheels weights, front tractor weights,

and/or tire ballast should be used to improve

stability.

• Drive Rotary Tiller diagonally over sharp dips and

avoid sharp drops to prevent tractor and Rotary

Tiller from “hanging up”. Always travel downward

on slopes, never across the face. Check tractor

manual for proper use on slopes.

• A minimum of 20% of the tractor and equipment

weight must be on the tractor’s front wheels.

Without this weight, the tractor could tip over,

causing personal injury or death. The weight may

be attained with a front-end loader, front wheel

weights, ballast in the tires or front tractor weights.

When attaining a minimum 20% of the tractor and

equipment weight on the front wheels, you must not

exceed the ROPS weight certification. Weigh the

tractor and equipment. Do NOT guess or estimate!

Pre-Operation

Instructions

IMPORTANT

-

Top and side gearboxes are shipped

without oil or grease in the fittings.

(1 qt. oil for top

gearbox and 3 qts. for side gearbox recommended).

USE 80W-90 GEAR OIL

• ALWAYS CHECK OIL IN GEARBOXES WITH

UNIT ON LEVEL GROUND BEFORE OPERATING.

Unit has two gearboxes, make sure both are filled

to specifications below using type 80W-90 gear

oil. DO NOT OVERFILL OR DAMAGE TO THE

GEARBOXES MAY RESULT.

Follow steps below:

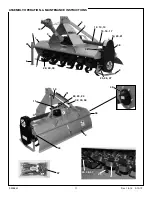

1) Remove 1/2” top vent plugs

and 1/8” overflow plugs from

gearboxes as shown in the

illustration. Fill gearboxes using

recommended gear oil until

oil begins to flow out from the

overflow plug hole.

2) Replace top vent and overflow plugs and wipe away

any excess oil. Be sure vent plugs are kept clear of any

dirt or debris to allow air to pass through.

3) Grease all zerks using SAE high temp multi-purpose

lithium grease.

4) With the Rotary Tiller positioned on level ground,

adjust the tractor lift arms so that when lifted, the rotor

bar remains parallel to the ground.

5) With the Rotary Tiller attached to the tractor, raise

and support the Tiller with secure blocking. Adjust the

skids located on the sides of the tiller. The adjustment

1/2” Top Vent

Plug

1/8”

Overflow Plug

ASSEMBLY, OPERATION, & MAINTENANCE INSTRUCTIONS

F-20979-4

5

Rev. 6-1-15 2-10-12