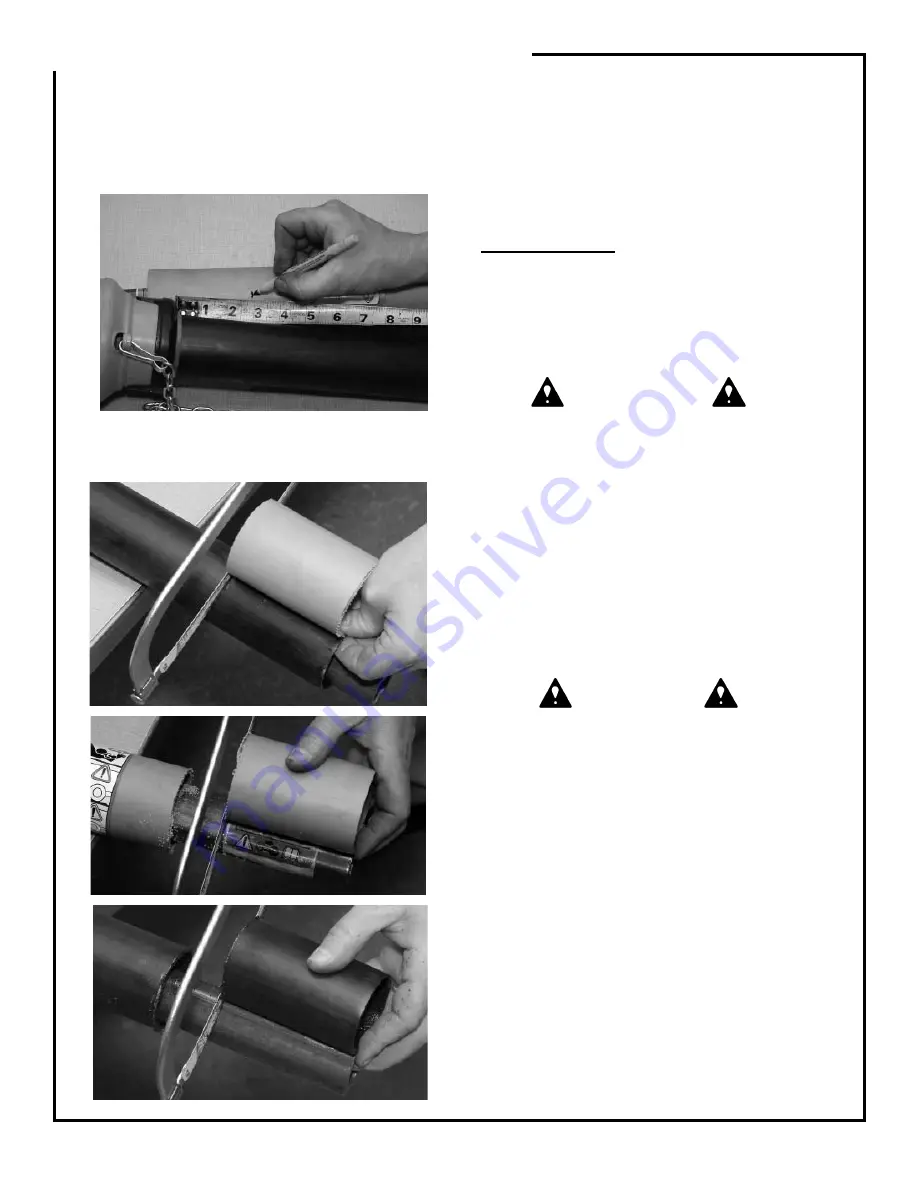

Cutting PTO Shaft

1. After determining how much to cut off, be sure to

cut off equal lengths of each PTO shaft section, but be

careful not to cut off too much. Clamp end of PTO shaft

in a vice, and cut off shield where marked. (See Fig. 1).

2. Using the cut section of the shield as a guide, cut

the same amount off of each shaft.

(See Fig. 2A, 2B & 2C).

3. Repeat Steps 1 and 2 for the other section of the

PTO shaft.

4. Use a file to deburr the PTO shafts. Clean up all

chips, burrs and filings from both ends of the PTO

shaft.

IMPORTANT NOTE:

If the bolt that attaches the

PTO shaft to the gearbox gets sheared, replace with

a

Grade 2 bolt ONLY.

Replacement with any other

grade of bolt will void your warranty and may cause

permanent damage to the PTO shaft, gearbox, or

tractor.

Attaching To Tractor

Never stand, or allow anyone else to stand, between

the tractor and the Tiller while backing the tractor

up to the hitch.

1) Attach to the tractor’s 3-Point hitch as described

in the Tractor’s Operator’s Manual. Set tractor’s lift

control stop at a position that will prevent the PTO shaft

from coming in contact with the front edge of the Tiller

when it is at full lift. Consult your tractor manual for

instructions.

2) Apply any multi-purpose grease to the outside of the

male (inner) PTO shaft section. Assemble PTO shaft

and install on Tiller and tractor.

Failure to install the retaining clip on the gearbox

input shaft would allow the driveline to swing freely

if the bolt is sheared causing possible injury or

death.

3) Pull shaft on tractor side of PTO shaft yoke to be

sure it has locked in place. Make certain PTO shaft

guards are in place and in good working condition.

4) The PTO shaft guard is a non-rotating design and

must be secured prior to equipment use. Use the

chain on each yoke guard to attach to fixed objects on

both the tractor and equipment ends that will not allow

the PTO shaft guard to rotate during operation.

WARNING

Fig. 1

Fig. 2A

Fig. 2B

Fig. 2C

DANGER

ASSEMBLY, OPERATION, & MAINTENANCE INSTRUCTIONS

F-20981-1

7

Rev. 4-27-12 2-10-12