Additional Installation Tips

6.3 To Achieve Better EMC Protection

•

Use shielded cables for RS232 communication.

•

Use twisted pair and shielded cabling for RS422 and RS485.

•

Use the cabling intended for the bus type; Ethernet, Profibus, CC-Link,

CAN, Device Net etc.

•

Install and connect according to applicable specifications for the relevant bus

standard.

•

Use shielded cabling for Ethernet, preferably with foil and a braided shield.

•

D-sub covers should be shielded, and the shield should be connected to the

cover 360° where the cable enters.

•

Connect the shield at both ends.

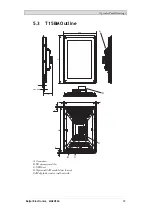

Shielded cable

Not same potential

Ground plane 1

Ground plane 2

Ground plate

Ground plate in another building

0.1

μ

F/250 V

With longer distances, there is a risk that the ground potential may be different.

In that case, the shield should only be connected at one end. A good alternative

is to connect the other end of the shield to the ground via a 0.1 μF/250 V plastic

capacitor. Both ends are then connected to the ground in terms of HF, but only

connected to the ground at one end in terms of LF, thus avoiding the 50/60 Hz

grounding loops.

Metal cabinet

Metal cabinet

Terminal or connector

Terminal or connector

EMC cable gland

Plastic cable gland

Shielded cable

Short distance

Cable clamp

in steel

Shielded cable

1. Use an EMC cable gland or regular plastic cable gland, remove the outer jacket

and connect the shield to the installation plate with a 360° metal cable clamp.

2. Place the 24 V DC and communications cabling in one cable trunk/cable duct

and 230/380 V AC in another. If the cables need to be crossed, cross them at

90° only. Avoid combining the cabling for stronger 24 V DC outputs with

the communication cabling.

Ferrite cores that are snapped onto the shielded cabling may remove minor

disturbances. Large ferrite pieces that are snapped onto unshielded cabling and

where the wires go 2-4 times around the cores are approximately 5-25 times more

efficient.

Beijer Electronics, MAEN166

23