User Guide Revision 1.12

20

4.

Electrical Installation

4.1.

Grounding the Drive

This manual is intended as a guide for proper installation. The Manufacturer cannot assume responsibility for the compliance or

the non-compliance to any code, national, local or otherwise, for the proper installation of this drive or associated equipment. A

hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

This drive contains high voltage capacitors that take time to discharge after removal of the main supply. Before working on the

drive, ensure isolation of the main supply from line inputs. Wait ten (10) minutes for the capacitors to discharge to safe voltage

levels. Failure to observe this precaution could result in severe bodily injury or loss of life.

Only qualified electrical personnel familiar with the construction and operation of this equipment and the hazards involved

should install, adjust, operate, or service this equipment. Read and understand this manual and other applicable manuals in

their entirety before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

4.1.1.

Grounding Guidelines

The ground terminal of each drive should be individually connected DIRECTLY to the site ground bus bar (through the filter if installed). Drive

ground connections should not loop from one drive to another, or to, or from any other equipment. Ground loop impedance must confirm to

local industrial safety regulations. To meet UL regulations, UL approved ring crimp terminals should be used for all ground wiring connections.

The drive Safety Ground must be connected to system ground. Ground impedance must conform to the requirements of national and local

industrial safety regulations and/or electrical codes. The integrity of all ground connections should be checked periodically.

4.1.2.

Protective Earth Conductor

The Cross sectional area of the PE Conductor must be at least equal to that of the incoming supply conductor.

4.1.3.

Safety Ground

This is the safety ground for the drive that is required by code. One of these points must be connected to adjacent building steel (girder, joist),

a floor ground rod, or bus bar. Grounding points must comply with national and local industrial safety regulations and/or electrical codes.

4.1.4.

Motor Ground

The motor ground must be connected to one of the ground terminals on the drive.

4.1.5.

Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist. The drive is designed to produce the minimum possible leakage current whilst

complying with worldwide standards. The level of current is affected by motor cable length and type, the effective switching frequency, the

earth connections used and the type of RFI filter installed. If an ELCB (Earth Leakage Circuit Breaker) is to be used, the following conditions

apply: -

A Type B Device must be used

The device must be suitable for protecting equipment with a DC component in the leakage current

Individual ELCBs should be used for each drive

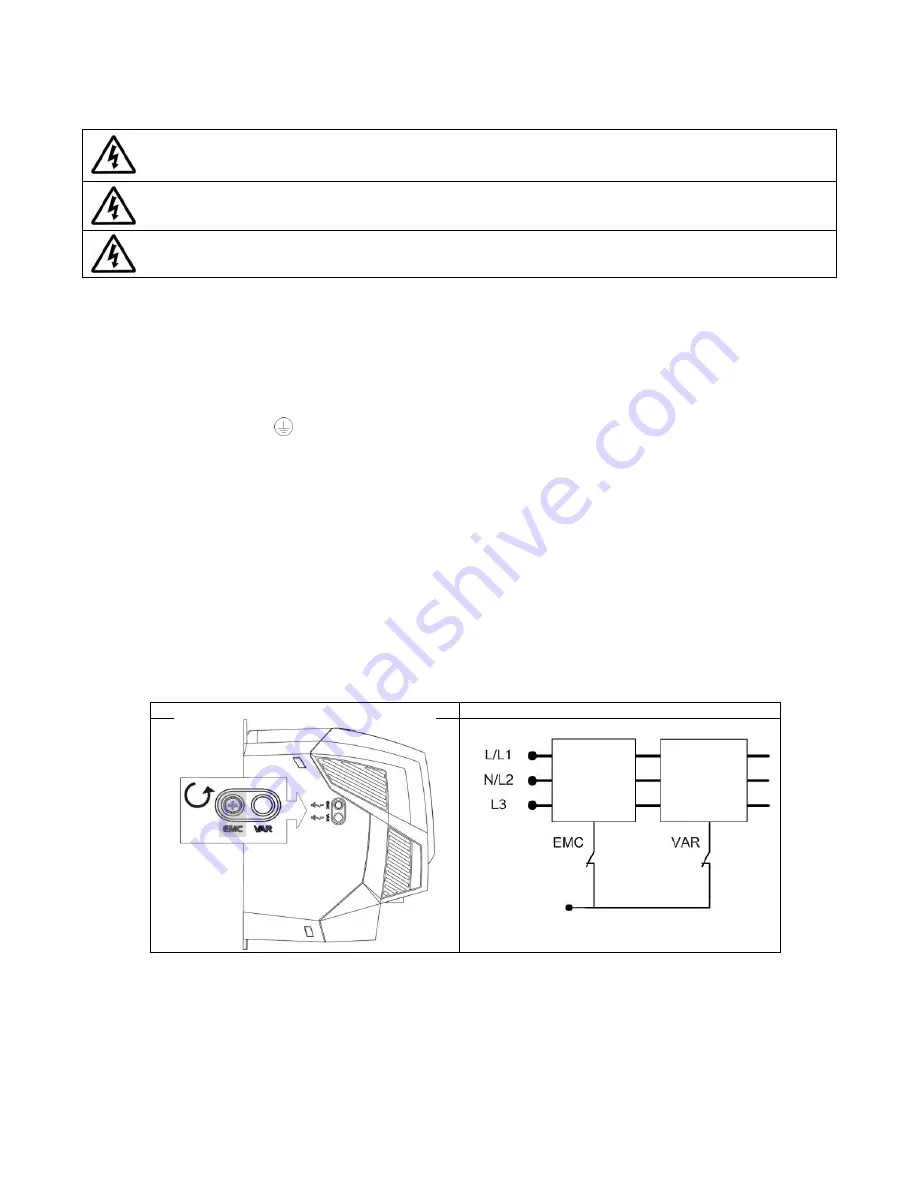

Drives with an EMC filter have an inherently higher leakage current to Ground (Earth). For applications where tripping occurs the EMC filter

can be disconnected (on IP20 units only) by removing the EMC screw on the side of the product.

Remove the screws as indicated below

The drive product range has input supply voltage surge suppression components fitted to protect the drive from line voltage transients,

typically originating from lightening strikes or switching of high power equipment on the same supply.

4.1.6.

Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the motor cable shield. The motor cable shield connected to this terminal (drive

end) should also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to the safety

ground terminal.

Internal

EMC

Filter

Internal

Surge

Protection

Earth

Summary of Contents for HVAC H2

Page 1: ......

Page 72: ...User Guide Revision 1 12 72 82 H2MAN BE_V1 11...