User Guide Revision 1.12

64

12.2.2.

Modbus Control & Monitoring Registers

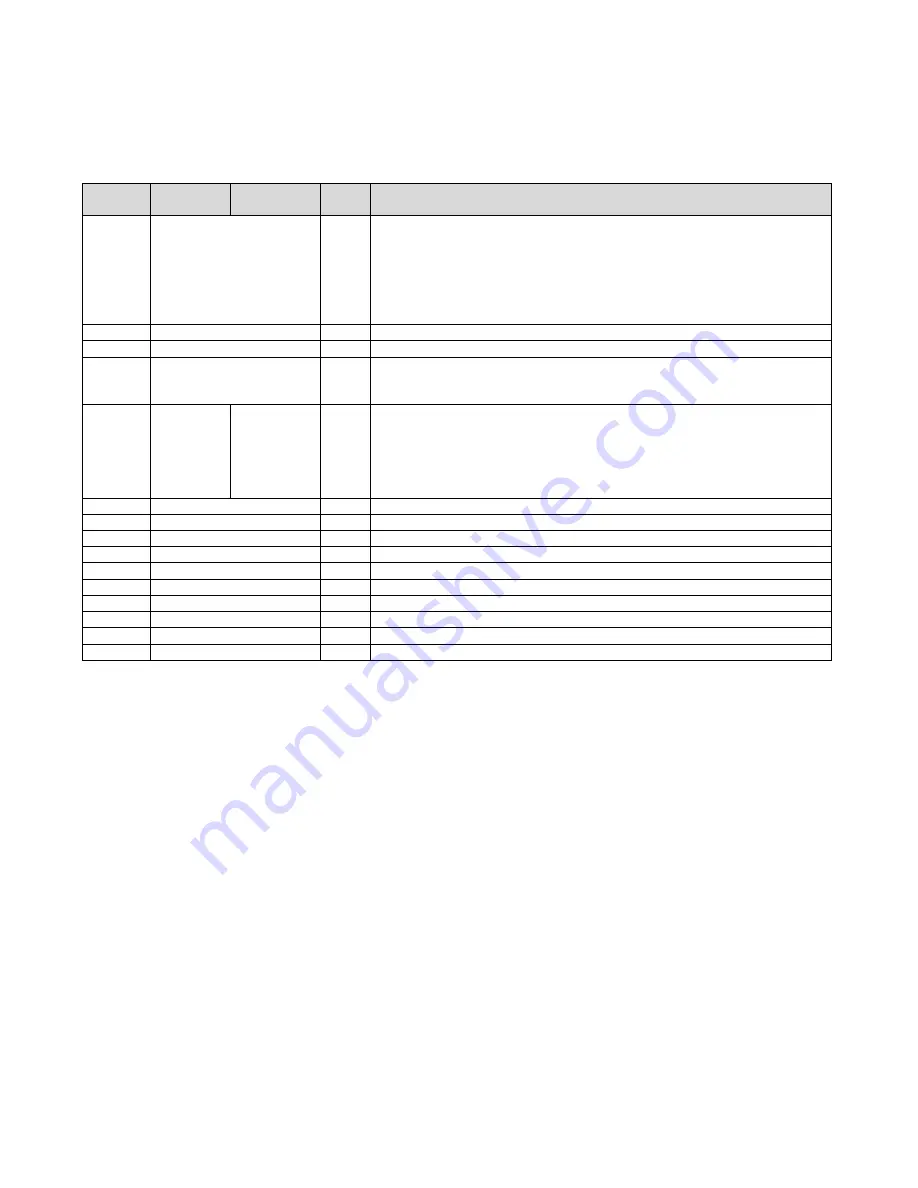

The following is a list of accessible Modbus Registers available in the drive.

Registers 1 and 2 can be used to control the drive providing that Modbus RTU is selected as the primary command source (P1-12 = 4)

Register 4 can be used to control the acceleration and deceleration rate of the drive providing that Fieldbus Ramp Control is enabled

(P5-07 = 1)

Registers 6 to 24 can be read regardless of the setting of P1-12

Register

Number

Upper Byte

Lower Byte

Read

Write

Notes

1

Command Control Word

R/W

Command control word used to control the drive when operating with Modbus RTU.

The Control Word bit functions are as follows :-

Bit 0 : Run/Stop command. Set to 1 to enable the drive. Set to 0 to stop the drive.

Bit 1 : Fast stop request. Set to 1 to enable drive to stop with 2

nd

deceleration ramp.

Bit 2 : Reset request. Set to 1 in order to reset any active faults or trips on the drive.

This bit must be reset to zero once the fault has been cleared.

Bit 3 : Coast stop request. Set to 1 to issue a coast stop command.

2

Command Speed Reference

R/W

Set-point must be sent to the drive in Hz to one decimal place, e.g. 500 = 50.0Hz

3

Command Torque Reference

R/W

Set-point must be sent to the drive in % to one decimal place, e.g. 2000 = 200.0%

4

Command Ramp times

R/W

This register specifies the drive acceleration and deceleration ramp times used when

Fieldbus Ramp Control is selected (P5-08 = 1) irrespective of the setting of P1-12. The

input data range is from 0 to 60000 (0.00s to 600.00s)

6

Error code

Drive status

R

This register contains 2 bytes.

The Lower Byte contains an 8 bit drive status word as follows :-

Bit 0 : 0 = Drive Disabled (Stopped), 1 = Drive Enabled (Running)

Bit 1 : 0 = Drive Healthy, 1 = Drive Tripped

The Upper Byte will contain the relevant fault number in the event of a drive trip.

Refer to section 15.1 for a list of fault codes and diagnostic information

7

Output Frequency

R

Output frequency of the drive to one decimal place, e.g.123 = 12.3 Hz

8

Output Current

R

Output current of the drive to one decimal place, e.g.105 = 10.5 Amps

9

Output Torque

R

Motor output torque level to one decimal place, e.g. 474 = 47.4 %

10

Output Power

R

Output power of the drive to two decimal places, e.g.1100 = 11.00 kW

11

Digital Input Status

R

Represents the status of the drive inputs where Bit 0 = Digital Input 1 etc

20

Analog 1 Level

R

Analog Input 1 Applied Signal level in % to one decimal place, e.g. 1000 = 100.0%

21

Analog 2 Level

R

Analog Input 2 Applied Signal level in % to one decimal place, e.g. 1000 = 100.0%

22

Pre Ramp Speed Reference

R

Internal drive frequency set-point

23

DC bus voltages

R

Measured DC Bus Voltage in Volts

24

Drive temperature

R

Measured Heatsink Temperature in °C

12.2.3.

Modbus Parameter Access

All User Adjustable parameters (Groups 1 to 5) are accessible by Modbus, except those that would directly affect the Modbus

communications, e.g.

P5-01 Drive Fieldbus Address

P5-03 Modbus RTU Baud Rate

P5-04 Modbus RTU Data Format

All parameter values can be read from the drive and written to, depending on the operating mode of the drive – some parameters cannot be

changed whilst the drive is enabled for example.

When accessing a drive parameter via Modbus, the Register number for the parameter is the same as the parameter number,

E.g. Parameter P1-01 = Modbus Register 101.

Modbus RTU supports sixteen bit integer values, hence where a decimal point is used in the drive parameter, the register value will be

multiplied by a factor of ten,

E.g. Read Value of P1-01 = 500, therefore this is 50.0Hz.

For further details on communicating with the drive using Modbus RTU, please refer to your local Sales Partner.

Summary of Contents for HVAC H2

Page 1: ......

Page 72: ...User Guide Revision 1 12 72 82 H2MAN BE_V1 11...