Additional Installation Tips

6.4 Ambient Temperature

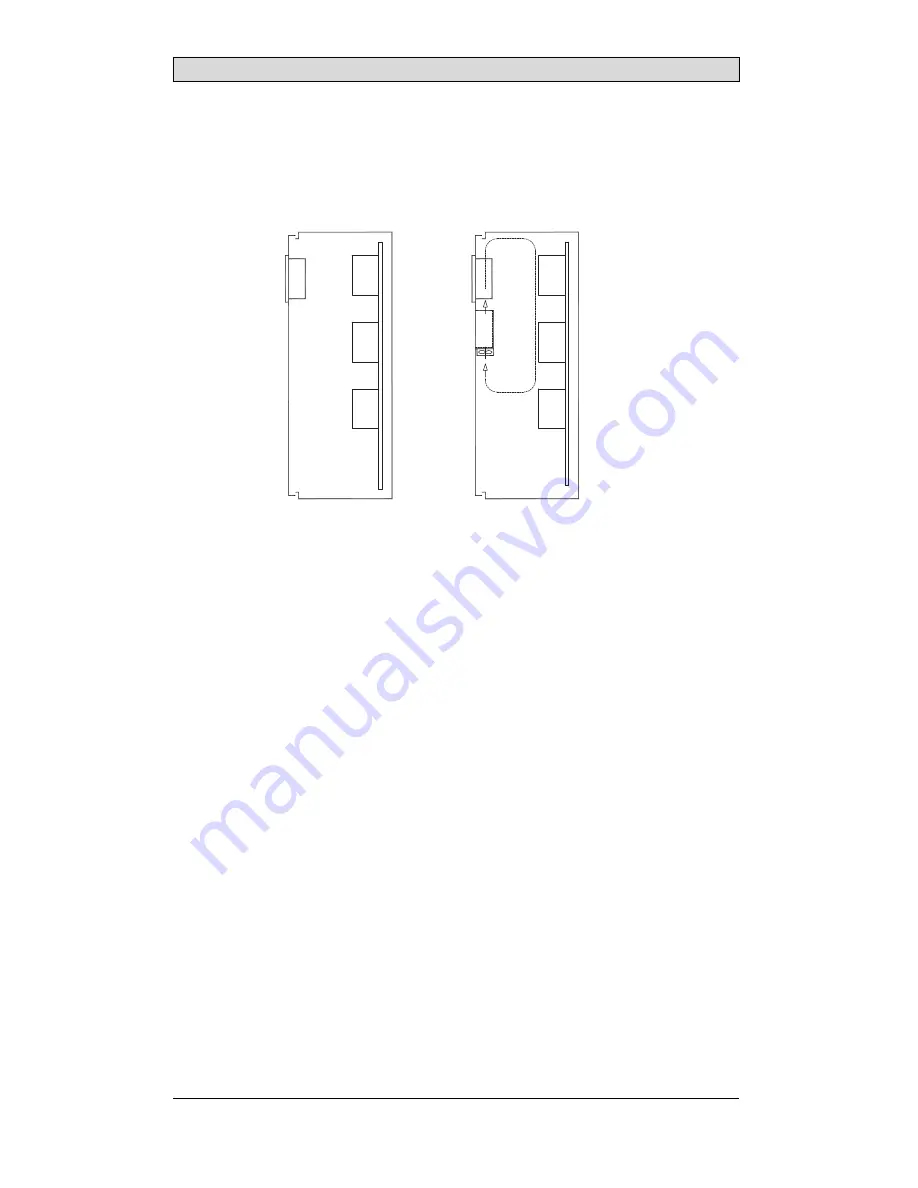

The maximum ambient temperature for the operator panel is provided in the

specifications. The ambient temperature refers to the temperature in the device

cabinet which cools the operator panel’s electronics.

Operator

panel

Power

Power

Power

30 °C outside

Top

50 °C inside

Bottom

40 °C inside

Middle

45 °C inside

Airflow

Axial fan

120 x 120 mm

In most cases, the ambient temperature for the operator panel is significantly

higher than the device cabinet’s ambient temperature.

If the cabinet is tall and there are a number of heat-generating devices, the

temperature at the top of the cabinet is considerably higher than the temperature

increase that would be expected. All electronics are sensitive to heat. The lifespan

of an electrolytic capacitor is cut in half with an 8-10 °C increase in temperature. A

15-20 °C temperature increase results in a quarter of the lifespan etc.

Rittal has a good program for estimating the anticipated average temperature in

the cabinet as well as a large program for controlling the temperature in the device

cabinet.

An enamel-coated steel cabinet has a radiant heat value of 5.5 W/m

2

and degrees

C.

Installing a fan inside the cabinet evens out the temperature, while moving air

provides considerably better cooling than still air.

Install the fan so that it sits in a cooler area and blows cold air against the operator

panel. If the fan is mounted at the top and sucks warm air upwards, the ambient

temperature of the fan becomes higher, resulting in a shorter lifespan.

An approximate value of the net power consumption for the operator panel can

be calculated by multiplying the supply voltage with the current drawn by the

operator panel. This is assuming that all supplied power is transformed to heat.

Beijer Electronics, MAEN185

25