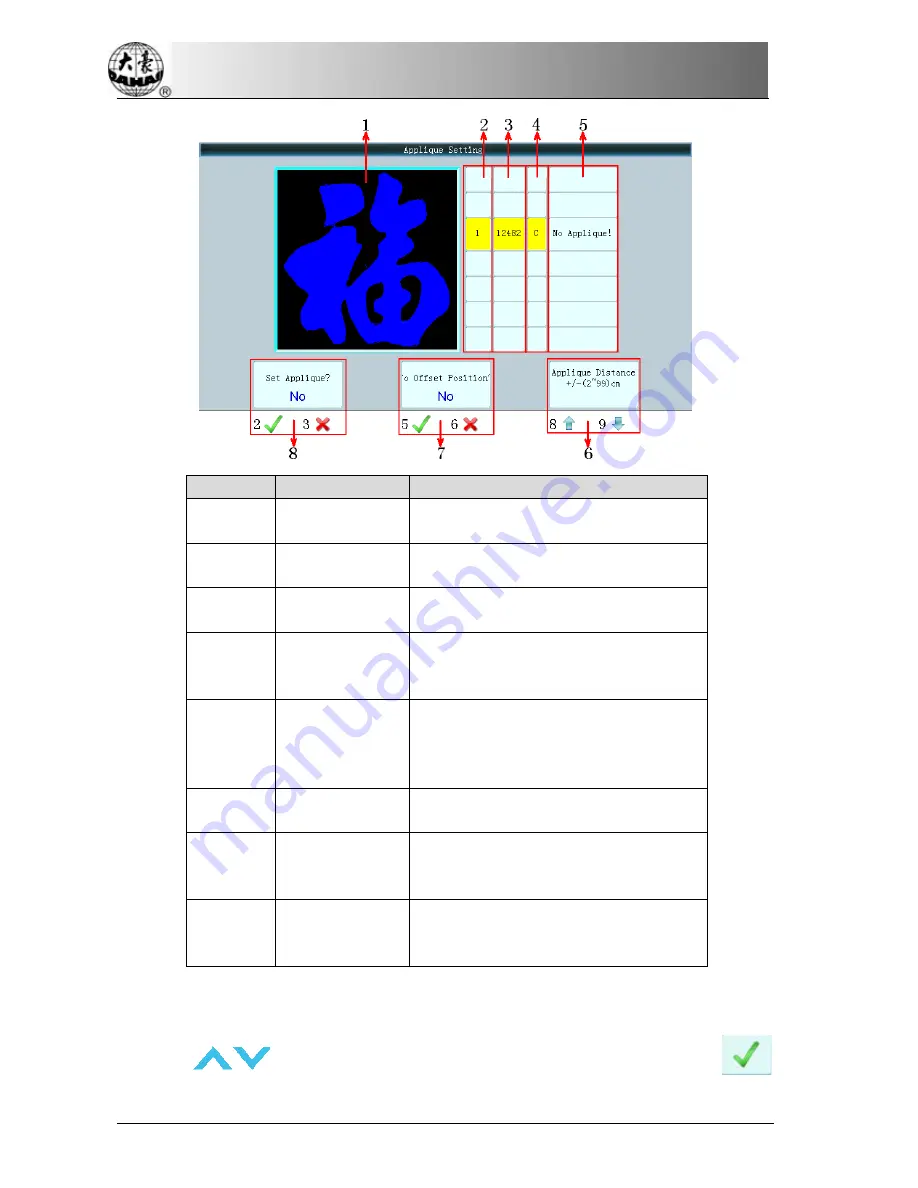

Chapter 4 Memory Design Management

Number

Name

Description

1

Design display

area

Real-time display of the design when

machine embroiders to the applique point

2

Sequence

number list

Show the sequence number of the

position to set applique point.

3

Stitch number

list

Display the stitch number at that

position.

4

Type list

The stitch code type

C: color-changing code

S: stop code

5

Option list

Type of applique at this position:

1

.

No applique

2

.

Set offset position

3

.

Applique distance

6

Frame-out

distance

Select the applique distance (frame-out):

(2cm to 99cm) or (-2cm to -99cm)

7

Whether to go to

the offset

position

Choose whether to set the offset position

8

Applique

embroidery

selecting list

Choose whether to set applique

embroidery.

The design display area shows the design which is being set with applique. After user sets the

applique position, the design will be refreshed and the result will appear directly.

4.

Press

to move the list to the position for applique. Then you can press

(which is after “Add Applique?”).

42 BECS- D56 computerized embroidery machine owner’s manual

Summary of Contents for BECS-D56

Page 2: ......