2.7

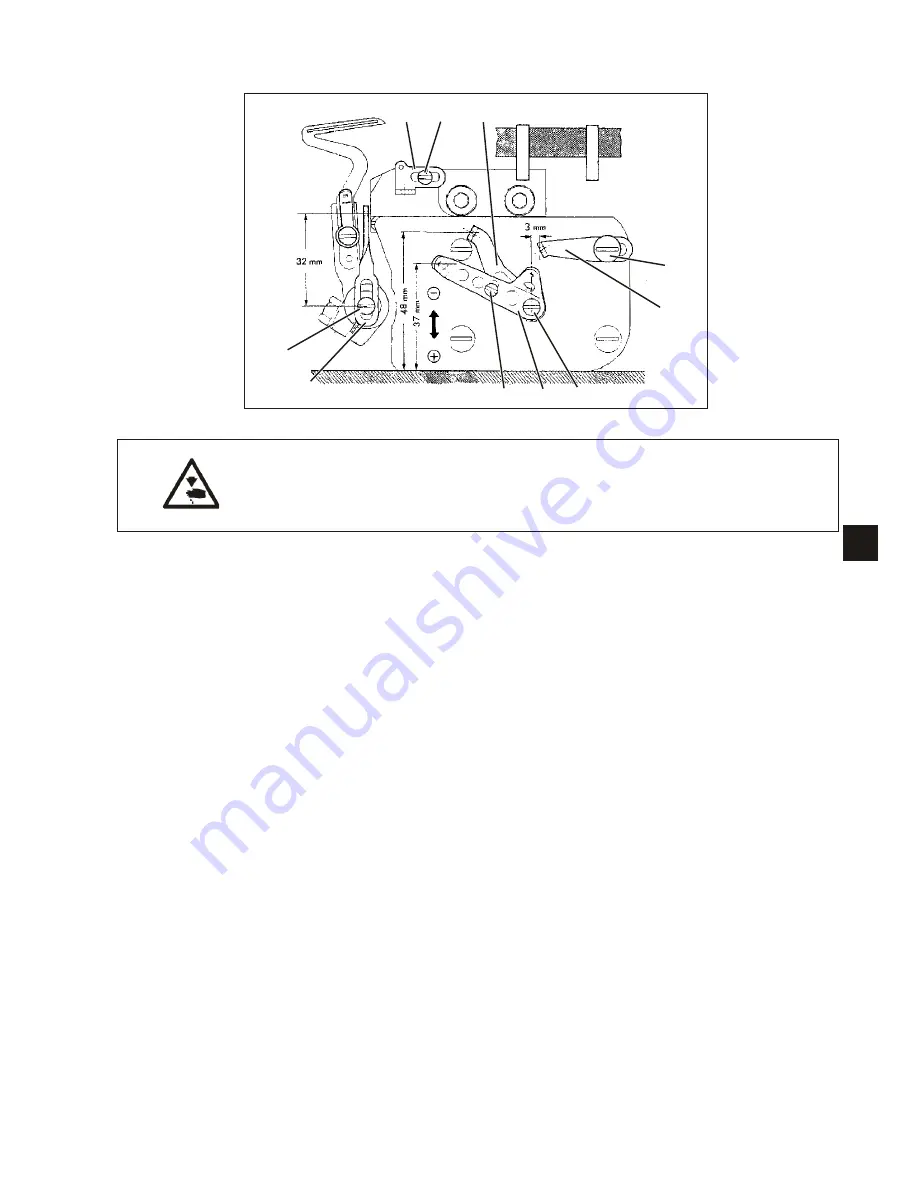

Thread regulation of overlock hook

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the thread regulation only with the sewing station

switched off.

Standard

The position of the individual thread guides or thread pullers is

dependent on the material, the sewing thread and the stitch type.

Therefore the following setting values have to be regarded as standard

values only.

Correction

–

Turn the handwheel until the right hook is in its top reverse point.

–

Loosen screw 10 and shift the thread puller 9 in such a way that

there is a distance of approx. 32 mm between the middle of the

screw and the middle of the eyelet.

–

Tighten screw 10.

Take care that the thread puller 9 is in vertical position.

–

Loosen screws 6 and 8 a little.

–

Position the thread pullers 3 and 7 as shown in the illustration.

–

Tighten screws 6 and 8.

–

Loosen screw 4 a little.

–

Position the thread guide 5 as shown in the illustration.

–

Tighten screw 4.

–

Loosen screw 2 a little.

–

Shift the thread guide 1 in such a way that the screw 2 is in the

centre of the longitudinal hole.

–

Tighten screw 2.

Note

If the seam requires more or less thread, shift the thread pullers 3 and

7 in the direction “+” or “-” respectively.

17

3

9

10

8

6

7

5

4

3

2

1

Summary of Contents for 1281/5

Page 2: ......

Page 54: ...1 7 8 4 2 5 6 3 9 ...

Page 62: ...Für Ihre Notizen 10 ...

Page 64: ......

Page 86: ...Note 24 ...