1 697 630 500

2013-03-05

|

Beissbarth GmbH

Product description | MS 65 OR RAC S80 | 7

en

3.6

Description of function

Below are reported the main functions of the listed

components of the

MS 65 OR RAC S80

:

R

Pedal box, comprehends control pedals of the

equipment (locking flange rotation pedal, bead brea-

king pedal, locking jaws pedal, tilting column pedal).

R

Bead breaker, for bead breaking of tires from the

rim; it is made of the bead breaking arm pneuma-

tically operated by a double effect cylinder (fitted

with a special device with three positions which, by

letting the blade open more widely, allows also bead

breaking of particularly wide tires), an arm positio-

ning lever, antiabrasive supports for rim support

during bead breaking phases.

R

Column assembly, made of a tilting column with

2 operating positions (which allows demounting

and mounting of tires on rims of remarkable width)

which holds the components needed to demount

(and mount) the tire from the rim: horizontal sliding

arm (with mounting lever), vertical sliding rod (with

locking knob), mounting tool for demounting (and

mounting) the tire from the rim with the help of the

bead lifting lever.

R

Locking plate, locking and rotation device (clockwise

and counterclockwise) of the rim, pneumatically

driven by 2 cylinders, made of 4 movable sliders

(adjustable for use also with wheels up to 26'') with

locking jaws for the internal and external locking of

the rim.

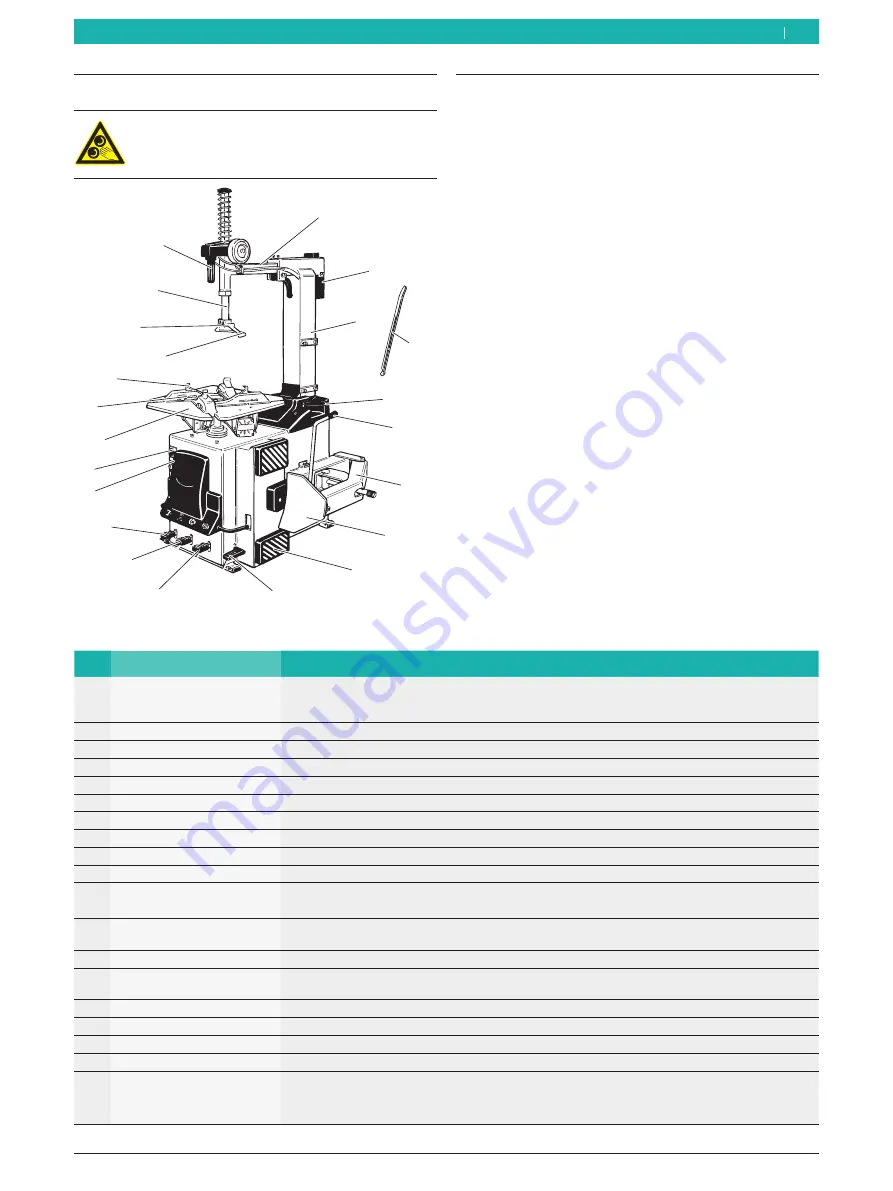

3.5

Description of unit

On the MS 65 OR RAC S80 there are rotating

and moving parts that could injure fingers

and arms.

2

4

3

1

5

7

8

13

12

14

15

18

17

16

6

20

9

10

21

19

652099-01_Mi

11

22

Fig. 1:

MS 65 OR RAC S80

Pos. Name

Function

1

Locking flange rotation pedal Locking plate rotation:

R

clockwise (press down the pedal)

R

counter-clockwise (lift the pedal from bottom to top)

2

Bead breaker pedal

Bead breaking arm activation.

3

Locking jaw pedal

Opening and closing of the locking plate jaws.

4

Tilting column pedal

Tilting column activation.

5

Bead breaking arm

Bead breaking of the tire from the rim.

6

Bead breaking arm lever

Bead breaking arm activation.

7

Bead breaker blade

Bead breaking.

8

Antiabrasive supports

Tire support for bead breaking operations.

9

Tilting column

Sliding arm and mounting tool support .

10

Horizontal sliding arm

Horizontal positioning of the mounting tool.

11

Locking lever

Tire locking of the horizontal sliding arm.

12

Vertical sliding rod

Vertical positioning of the mounting tool.

13

Vertical rod locking lever

Tire locking of the vertically sliding rod. Operating on the knob it is possible to achieve a 3 mm

spacing (adjustable) from the edge of the rim.

14

Mounting tool

Mounting and demounting of the tire from the rim (with the help of the bead lifting lever).

15

Sliding roller

To be inserted in the mounting tool BOX, to avoid any kind of friction between the rim and the mounting

tool during tire mounting and demounting phases. For the alloy rims a special "tab" is arranged.

16

Locking plate

Locking and rotation of the rim.

17

Movable lanes

Positioning of the locking jaws.

18

Locking jaws

Internal or external locking of the rim.

19

Grease cup holding ring

Mounting paste containing support.

20

Bead lifting lever

Lifting of the tire edge in demounting and mounting phases.

21

Speed switch

Passing from the first to the second speed.

22

2 position column switch

Operation of the 2 position column (lifting and lowering).