4

3.2 4/20mA input

In Europe, sources of energy which do not

generate more than 1.5V; 100mA or 25mW are, for

intrinsic safety purposes, considered to be

simple

apparatus

(Clause 5.7 of EN 60079-11).

Although the BA307C and BA308C indicators do

not themselves comply with the requirements for

simple

apparatus

, the EC-Type Examination

Certificate specifies that under fault conditions the

voltage, current and power at the 4/20mA input

terminals 1 & 3 will not exceed those specified for

simple apparatus

. This allows the BA307C and

BA308C to be connected into any intrinsically safe

circuit protected by a Zener barrier or galvanic

isolator providing the output parameters of the

circuit do not exceed:

Uo

=

30V dc

Io

=

200mA

Po

=

0.85W

The EC-Type Examination Certificate specifies that

the maximum equivalent capacitance and

inductance between the two 4/20mA input

terminals 1 and 3 is:

Ci

=

20nF

Li

=

10

H

To determine the maximum permitted cable

parameters, these figures should be subtracted

from the maximum cable capacitance and

inductance permitted by the certificate for the loop

into which the indicator is installed.

3.3 Zones, gas groups and T rating

The BA307C and BA308C have been certified as

Group II, Category 1G, EEx ia IIC T5 apparatus at

Tamb –40 to 60

o

C. When connected to a suitable

system the instruments may be installed in:

Zone 0 explosive gas air mixture

continuously present.

Zone 1 explosive gas air mixture likely to

occur in normal

operation.

Zone 2 explosive gas air mixture not

likely to occur, and if it does

will only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

Having a temperature classification of:

T1

450

o

C

T2

300

o

C

T3

200

o

C

T4

135

o

C

T5

100

o

C

At ambient temperatures between –40 & +60

o

C.

Note: Operation only specified between –20

o

C and

+ 60

o

C.

This allows both indicators to be installed in all

Zones and to be used with most common Industrial

gases.

WARNING installation in Zone 0

When installed in a Zone 0 potentially

explosive atmosphere requiring apparatus

of Category 1G, the indicator shall be

installed such that even in the event of rare

incidents, an ignition source due to impact

or friction between the aluminium enclosure

at the rear of the instrument mounting panel

and iron/steel is excluded.

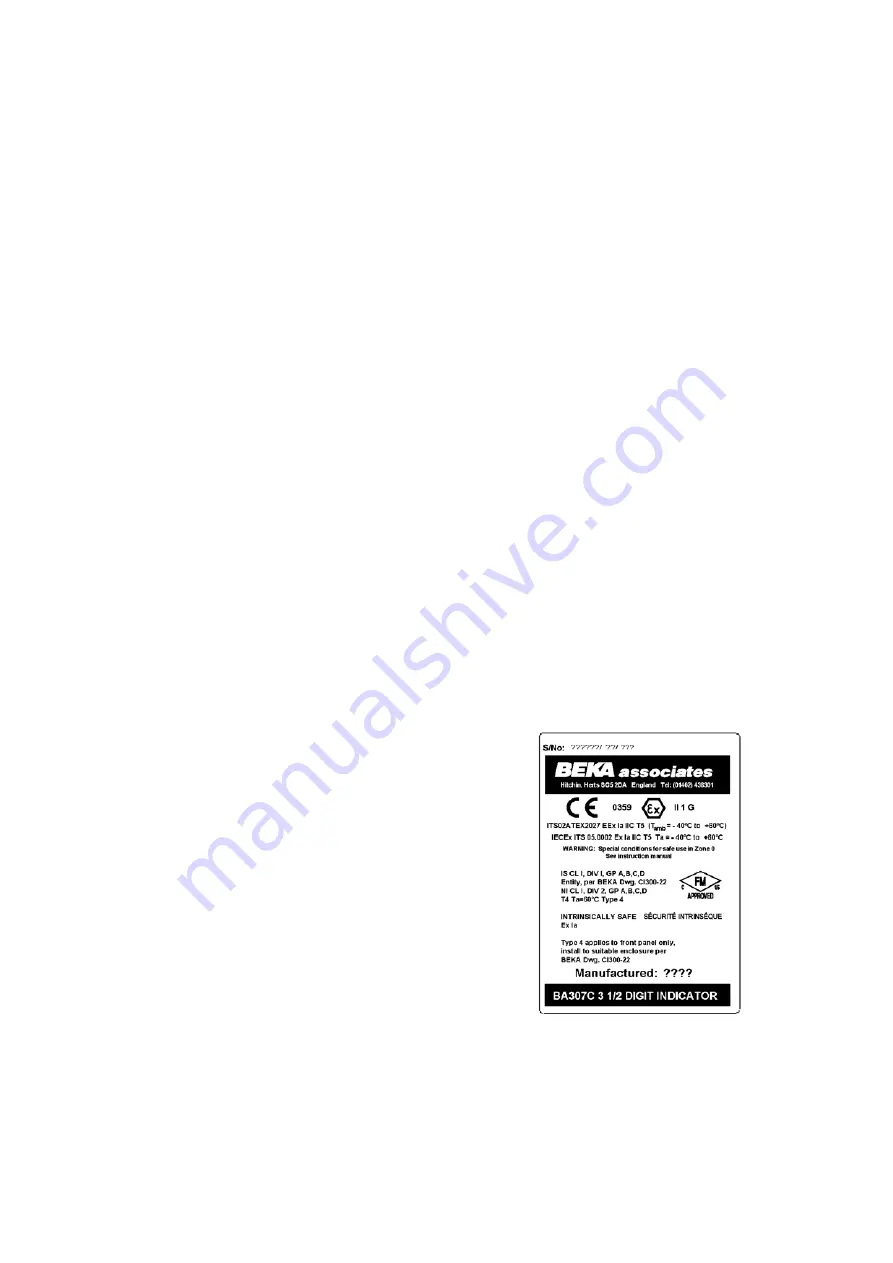

3.4 Certification label information

The certification label is fitted in a recess on the

top outer surface of the enclosure. It shows the

ATEX certification information, instrument serial

number, year of manufacture plus BEKA

associates’ name and location. Non European

certification information may also be included.

BA307C certification label