13

6.4 Position of the decimal point: ‘dP’

A dummy decimal point can be positioned between

any of the digits or it may be absent. To position

the decimal point select 'dP' from the menu and

press

P

. The decimal point can be moved by

pressing the

▲

or

▼

push button. If a decimal

point is not required it should be positioned beyond

the most or least significant digit. When

positioned as required press the

E

button to enter

the selection and return to the configuration menu.

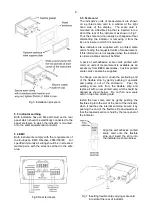

6.5 Calibration using an external

current source: ‘CAL’

This function enables the zero and span of the

indicator to be adjusted using an external

calibrated current source. When used with an

accurate traceable current source this is the

preferred method of calibration.

Zero is the indicator display with 4mA input

Span is the indicator display with 20mA input

To calibrate the indicator select 'CAL' from the

configuration menu and press

P

.

The indicator will

display 'ZEro' which is a request for a 4mA input

current. Adjust the external current calibrator to

4.000mA and again press

P

which will reveal the

current zero display. The flashing digit of the

indicator display can be changed by pressing the

▲

or

▼

buttons, when set as required pressing

P

will transfer control to the next digit. When all the

digits have been adjusted, press

E

to enter the

new zero and return to the 'ZEro' prompt .

Pressing the

▲

button will cause the indicator to

display 'SPAn' which is a request for a 20mA input

current. Adjust the external current calibrator to

20.000mA and again press

P

which will reveal the

existing span display. The flashing digit of the

indicator display can be changed by pressing the

▲

or

▼

buttons, when set s required pressing

P

will transfer control to the next digit. When all the

digits have been adjusted press

E

t

o enter the new

span and return to the 'SPAn' prompt. Finally

press

E

again to return to the configuration menu.

Notes:

a. The indicator input current must be adjusted to

the required value before the zero and span

functions are entered by pressing the

P

button.

b. Indicators may be calibrated at currents other

than 4 and 20mA, withiin the range 3.8 to

21.0mA providing the difference between the

two currents is greater than 4mA. If these

conditions are not complied with, the indicator

displays ‘FaiL’ and aborts the calibration.

c. If the zero current is greater than the span

current the instrument will be reverse acting

i.e. an increasing input current will cause the

display to decrease.

6.6 Calibration using internal reference:

‘SEt’

Using the ‘SEt’ function the indicator can be

calibrated without the need to know the value of

the 4/20mA input current, or to disconnect the

indicator from the 4/20mA loop.

When using the ‘Set’ function the indicator’s

internal reference is used to simulate a 4mA and

20mA input current.

Zero is the display with a simulated 4mA input

Span is the display with a simulated 20mA input

To calibrate the indicator display select 'SEt' from

the configuration menu and press

P

.

The indicator

will display 'ZEro', pressing

P

again will reveal the

current display at 4mA. The flashing digit can be

adjusted by pressing the

▲

or

▼

buttons, when

the flashing digit is correct pressing

P

will transfer

control to the next digit. When all the digits have

been adjusted, press

E

to return to the 'ZEro'

prompt.

To adjust the display at 20mA, press the

▲

button

which will cause the indicator to display 'SPAn',

pressing

P

will then reveal the indicator’s existing

display at 20mA. The flashing digit can be

adjusted by pressing the

▲

or

▼

buttons, when

the flashing digit is correct pressing

P

will transfer

control to the next digit. When all the digits have

been adjusted press

E

t

o return to the 'SPAn'

prompt followed by

E

to return to the ‘SEt’ prompt

in the configuration menu.

6.7 Bargraph format and calibration: ‘bAr’

Only the BA327NE has a bargraph

In addition to a five digit numerical display the

BA327NE has a 31 segment analogue bargraph

which may be configured to start and finish

anywhere within the indicator’s numerical display

range.

To configure the bargraph select 'bAr' from the

configuration menu and press

P

.

The indicator will

display 'tYPE', pressing

P

again will reveal the

existing bargraph justification which can be

changed to one of the following four or five options

using the

▲

or

▼

button:

Bargraph justification starts from

‘LEFt’

Left end of display

‘CEntr’

Centre of display

‘riGHT’

Right end of display

‘AlrSP’

Only with alarms – see section 9.3

‘oFF’

Bargraph disabled

When set as required press

E

to return to the

‘tYPE’ sub-function prompt.