15

7. LINEARISER

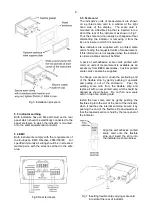

A sixteen segment, seventeen breakpoint (0 to 16)

lineariser may be selected in the ‘FunC’ section of

the configuration menu. The starting point and

slope of each straight line segment are fully

adjustable allowing the indicator to display most

non-linear process variables in linear engineering

units. Each break-point must occur at a current

greater than the preceding break-point and less

than the following break-point, in the range 3.8 to

21.0mA. If this requirement is not observed when

configuring the lineariser the indicator will display

'FaiL' and the configuration adjusted which

produced the error message will be ignored. Fig 9

shows a typical linearised indicator characteristic.

Fig 9 shows a typical linearising characteristic

Selecting ‘Lin’ in the ‘FunC’ section of the

configuration menu activates the lineariser, this

does not change the configuration menu shown in

Fig 8, but the 'CAL' and 'SEt' functions are

extended as shown in Fig 10. As with a linear

indicator, calibration of the lieariser may be

performed with an external current source using

the 'CAL' function, or with the internal reference

using the 'SEt' function.

The lineariser calibration is retained irrespective of

how the indicator function ‘FunC’ is subsequently

changed. It is therefore possible to select and

deselect the lineariser without having to

reconfigure it each time.

The lineariser calibration may be reset to the

factory default settings without changing the

indicator configure uing the 'LtAb' function

described in section 6.11.

7.1 Lineariser calibration using an external

current source.

This method allows direct calibration of the

lineariser with an external current source and is the

preferred method when traceability is required. If

the exact system non-linearity is unknown, this

method also allows direct calibration from the

variable to be displayed. e.g. the output from a

level sensor in an irregular tank may be displayed

in linear volumetric units by filling the tank with

known incremental volumes and calibrating the

indicator to display the sum of the increments at

each break-point.

The number of break-point required should first be

entered using the 'Add' and 'dEL' functions. In

both these sub-functions the indicator initially

displays the current break-point and the total

number of break-points being used as shown

below.

Display

Description of function

'Add'

Add a break-point

Adds a new break-point before the

displayed break-point. The calibration

of existing break-points is not changed,

but the identification number of all

subsequent break-points is increased

by one.

'dEL'

Remove a break-point

Removes the displayed break-point and

joins the preceding break-point to the

following break-point with a straight

line. The identification number of all

subsequent break-points is decreased

by one.

To add a break-point use the

▲

or

▼

button to

select 'CAL' from the configuration menu and press

P

which will result in the

'Add' sub-function prompt

being displayed. To enter the sub-function press

P

which will reveal the current break-point and the

total number of break-points which have already

been entered. When adding a break-point to a

calibrated indicator, the insertion position for the

new segment can be selected using the

▲

and

▼

push buttons. Each subsequent operation of the

P

push button will introduce an additional break-

point up to the maximum of 'n:16'.