26

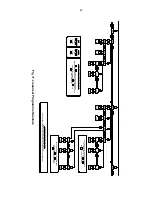

Inclusion of the lineariser software extends the

'CAL' and 'SEt' functions as shown in Fig 17,

and the root and null functions are omitted.

from the main menu.

As with a linear

indicator, calibration may be performed with an

external calibrator using the 'CAL' function, or

from the internal references using the 'Set'

function.

9.3.1 Calibration using an external current

source: CAL

This method allows direct calibration with a

current source, and

is preferred

when

traceability is required.

If the exact system

non-linearity is unknown, the method also

allows direct calibration from the variable to be

displayed. e.g. The output from a level sensor

in an irregular tank may be displayed in

linear volumetric units by filling the tank with

known incremental volumes and calibrating the

indicator to display the sum of the increments

at each break-point.

The number of break-points required must first

be entered using the Add and dEL functions.

In both these functions the indicator initially

displays the current break-point and the total

number of break-points being used. e.g.

5 13

current total number of

break-point break-points

Display Description of function

'Add'

Add a break-point

Adds a new break-point before the

displayed

break-point.

The

calibration of existing break-points

is

not

changed,

but

the

identification

number

of

all

subsequent

break-points

is

increased by one.

'dEL'

Remove a break-point

Removes the displayed break-point

and joins the preceding break-point

to the following break-point with a

straight line.

The identification

number of all subsequent break-

points is decreased by one.

To add a break-point select 'CAL' from the

main menu and press

P

to enter the 'Add'

function; press

P

again to reveal the current

and total number of break-points.

Each

subsequent operation of the

P

push button will

introduce an additional break-point.

When

adding a break-point to a calibrated indicator,

the insertion position can be selected using the

Up

and

Down

push buttons.

The delete break-point function dEL operates

in a similar manner to the Add function

described above.

When the required number of break-points has

been entered, return to the sub-menu by

pressing

E.

The indicator will display 'Add' or

'dEL' depending upon the last function used.

Each break-point can now be programmed.

Select 'PtS' from the sub-menu and press

P

which will select the first break-point '0

n',

where n is the total number of break-points

entered.

The selected break-point can be

changed using the

Up

and

Down

buttons.

When the required break-point has been

selected press

P

.

Set the indicator input

current to the exact value at which the break-

point is to occur, and adjust the indicator

display using the

Up

and

Down

buttons and

P

to move between digits. When the required

display has been set, press

E

to enter the

information and return to the sub-menu from

which another break-point can be selected.

Repeat this procedure for each break-point,

and then return to the main menu by pressing

E

twice.

9.3.2 Calibration using internal references:

SEt

This function enables the break-points to be

adjusted without the need for an accurate

external

current

source.

Throughout

calibration the indicator input current may be

any value between 4 and 20mA.

The accuracy of this method depends upon the

accuracy of the internal references which

should be calibrated periodically against a

traceable external current source with a

resolution of at least 0.4µA.

See section

6.10.2

Summary of Contents for ba326c

Page 11: ...11...