3

1.

DESCRIPTION

The BA326C is an intrinsically safe, panel

mounting, loop powered 4/20mA combined

bargraph and digital indicator.

The one

hundred segment bargraph provides a quick

indication of input current magnitude and

trend, supported by an accurate digital display

which may be calibrated in engineering units.

The

BA326C

is

a

second

generation

instrument which, although having additional

functions, remains compatible with the original

BA326B.

The main application of the BA326C is to

display a measured variable or control signal in

a hazardous process area. The zero and span

of the digital display are independently

adjustable so that the indicator may be

calibrated to display any 4/20mA variable in

engineering units.

The analogue display

shows the 4/20mA input on a single or double

100 segment bargraph which may be fitted

with a custom scale to indicate the units of

measurement.

Both the bargraph and digital

display may be offset to indicate deviation from

a specified input current.

The BA326C and the optional accessories

have been certified intrinsically safe for use in

gas hazardous areas by Notified Body Intertek

Testing and Certification Ltd. This certification

has been used to confirm compliance with the

European ATEX Directive 2014/34/EU.

The EC-Type Examination Certificate specifies

that under fault conditions the output voltage,

current and power at input terminals 1 and 3

will not exceed those specified for

simple

apparatus

in Clause 5.7 of EN60079-11.

This instruction manual describes ATEX

certification for BA326C instruments with serial

numbers above 071235/01/001. International

IECEx certification is described in Appendix 1.

BA326C indicators with serial numbers above

071235/01/001 are not FM approved.

The BA326C indicator is housed in a robust

144 x 48 panel mounting DIN enclosure with

an IP65 sealed front.

2.

OPERATION

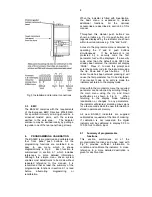

Fig 1 shows a simplified block diagram of a

BA326C.

The 4/20mA input current flows

through resistor R1 and forward biased diode

D1. The voltage developed across D1, which

is relatively constant, is multiplied by a switch

mode power supply and used to power the

instrument. The voltage developed across R1,

which is proportional to the 4/20mA input

current, provides the input signal for the

analogue to digital converter.

Each time a 4/20mA current is applied to the

instrument, initialisation is performed. After a

short delay the following display sequence

occurs:

Firmware

In form x.xx version

displayed.

-1.8.8.8.

Display test in which

all segments of the

display are activated.

Input current

Using calibration

display in

information stored in

engineering instrument

memory.

units.

Fig 1 Simplified block diagram of BA326C

Summary of Contents for ba326c

Page 11: ...11...