13

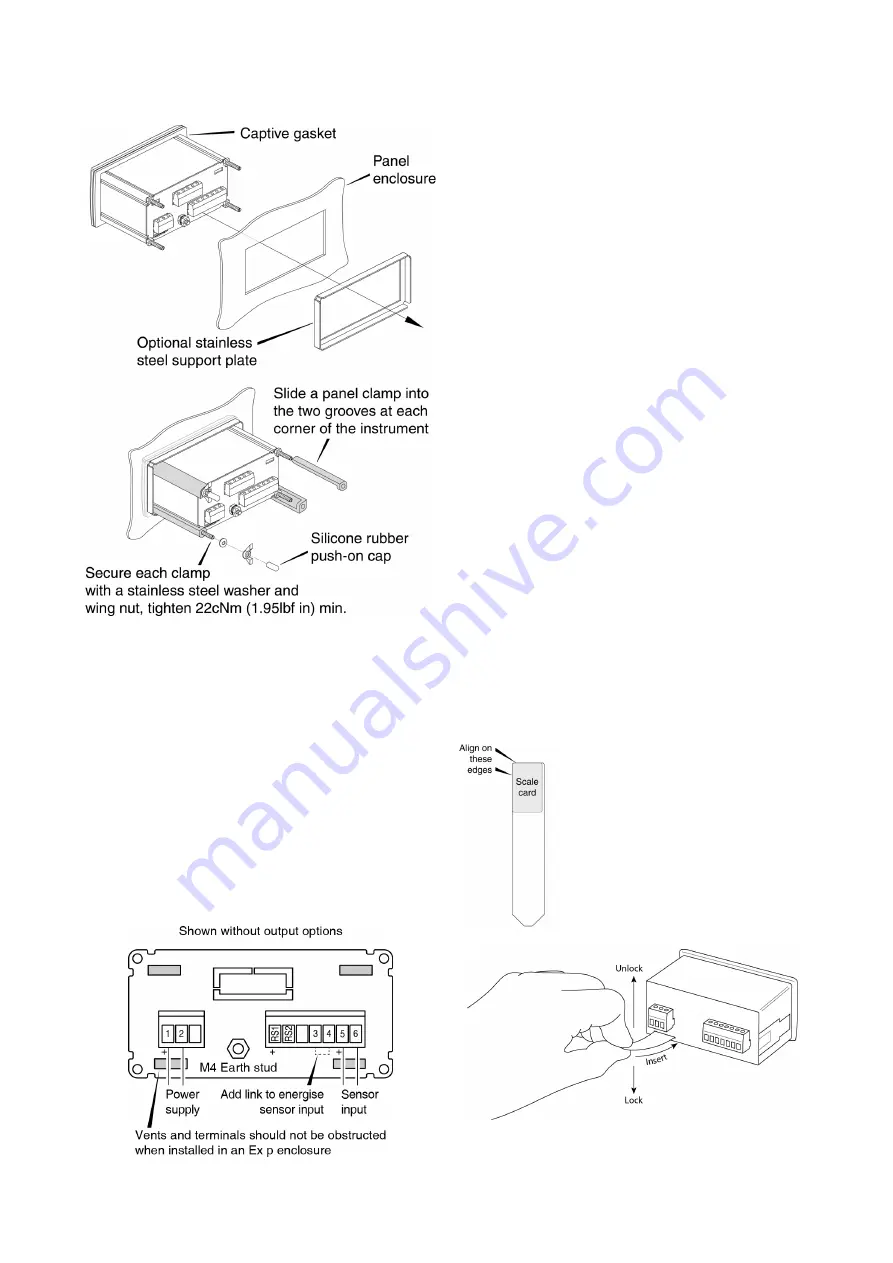

Fig 8 Installation procedure

4.3 Timer or Clock earthing

The BA377NE has an M4 earth stud on the rear

panel which should be electrically connected to the

panel enclosure in which the Timer or Clock is

mounted, or to the plant equipotential conductor.

4.4 EMC

The BA377NE complies with the requirements of the

European EMC Directive 2014/30/EU. For specified

immunity all wiring should be in screened twisted

pairs, with the screens earthed in the safe area.

Fig 9 Rear terminals without accessories

4.5

Scale card

The BA377NE's units of measurement are shown on

a printed scale card in a window at the right hand

side of the display. The scale card is mounted on a

flexible strip that is inserted into a slot at the rear of

the instrument as shown in Fig 10. Thus the scale

card can easily be changed without removing the

BA377NE from the panel or opening the instrument

enclosure.

New instruments are supplied with a printed scale

card showing the requested units of measurement, if

this information is not supplied when the instrument

is ordered a blank card will be fitted.

A pack of self-adhesive scale cards printed with

common units of flow measurement is available as

an accessory from BEKA associates.

Custom

printed scale cards can also be supplied - see 5.3

To change a scale card, unclip the tapered end of

the flexible strip at the rear of the instrument by

gently pushing it upwards and pulling it out of the

enclosure.

Peel the existing scale card from the

flexible strip and replace it with a new printed card,

which should be aligned as shown below. Do not fit

a new scale card on top of an existing card.

Install the new scale card by gently pushing the

flexible strip into the slot at the rear of the

instrument, when it reaches the internal end-stop

secure it by pushing the end of the flexible strip

downwards so that the tapered section is held by the

rear panel.

Align the self-adhesive printed scale

card onto the flexible strip and insert

the strip into the instrument as shown

below.

Fig 10 Inserting the flexible strip carrying the scale

card into slot at the rear of the instrument.

Summary of Contents for BA377NE

Page 1: ...Issue 6 3rd July 2018 BA377NE Rugged one input Ex nA and Ex tc Timer or Clock Issue 6...

Page 4: ...4...

Page 24: ...24...

Page 25: ...25...

Page 36: ...36...