10

4.

SYSTEM DESIGN FOR HAZARDOUS

AREAS.

When correctly installed in Zone 2 the BA384NG

Rate Totaliser may be connected to almost any

pulse output flowmeter in the safe area and to Ex n,

Ex e, Ex p and Ex d protected pulse output

flowmterers located in Zone 2. Because the

BA384NG is not certified intrinsically safe it should

not be connected to an intrinsically safe system.

BEKA Application Guide AG310,

Guide for

Installation of [extra low voltage d.c.] Ex nA

instrumentation

, which can be downloaded from

www.beka.co.uk, contains explanations and

recommendations for the installation of Ex nA

equipment.

In addition to being able to be connected to

flowmeters in the safe area and in Zone 2, the

BA384NG may also be connected to suitably

protected and certified flowmeters located in Zone 1.

This is explained in Application Guide AG310.

There are four design requirements:

1. The BA384NG should be powered from a

circuit that has output safety parameters in

normal operation equal to, or less than, the

input safety parameters for terminals 1 and 2

specified by the BA384NG ATEX Type

Examination Certificate.

2. BA384NG input, reset and output terminals

should only be connected to circuits having

safety parameters in normal operation

compliant with the BA384NG safety

parameters which are specified by the ATEX

Type Examination Certificate.

3. Hazardous area apparatus to which the

BA384NG is connected should be protected by

a technique suitable for the Zone in which the

equipment is located, such as Ex n or Ex e if

located in Zone 2. Equipment protected by

intrinsic safety should not be connected to a

BA384NG.

4. Wiring should comply with Clause 9 of

EN 60079-14.

When designing a system it is important to

remember that terminals 2, 6, 10 and RS2 are

interconnected within the BA384NG. See Fig 1.

4.1 Power supply

The BA384NG Rate Totaliser requires a minimum of

10V between terminal 1 & 2 and consumes:

10mA

without optional backlight

plus

6mA

when terminals 3 & 4 are linked

plus

6mA

when terminals 7 & 8 are linked

plus 16mA

with optional backlight

A 24V dc regulated, current limited supply located in

a safe area is suitable.

The power supply should meet the requirements for

personnel safety so that ‘live maintenance’ can

safely be performed. The implicit requirement for

galvanic isolation from the mains supply ensures

that the possible difficulties from circulating earth

currents caused by mains faults is minimised. In

European terms if the power supply is CE marked it

is almost certainly acceptable.

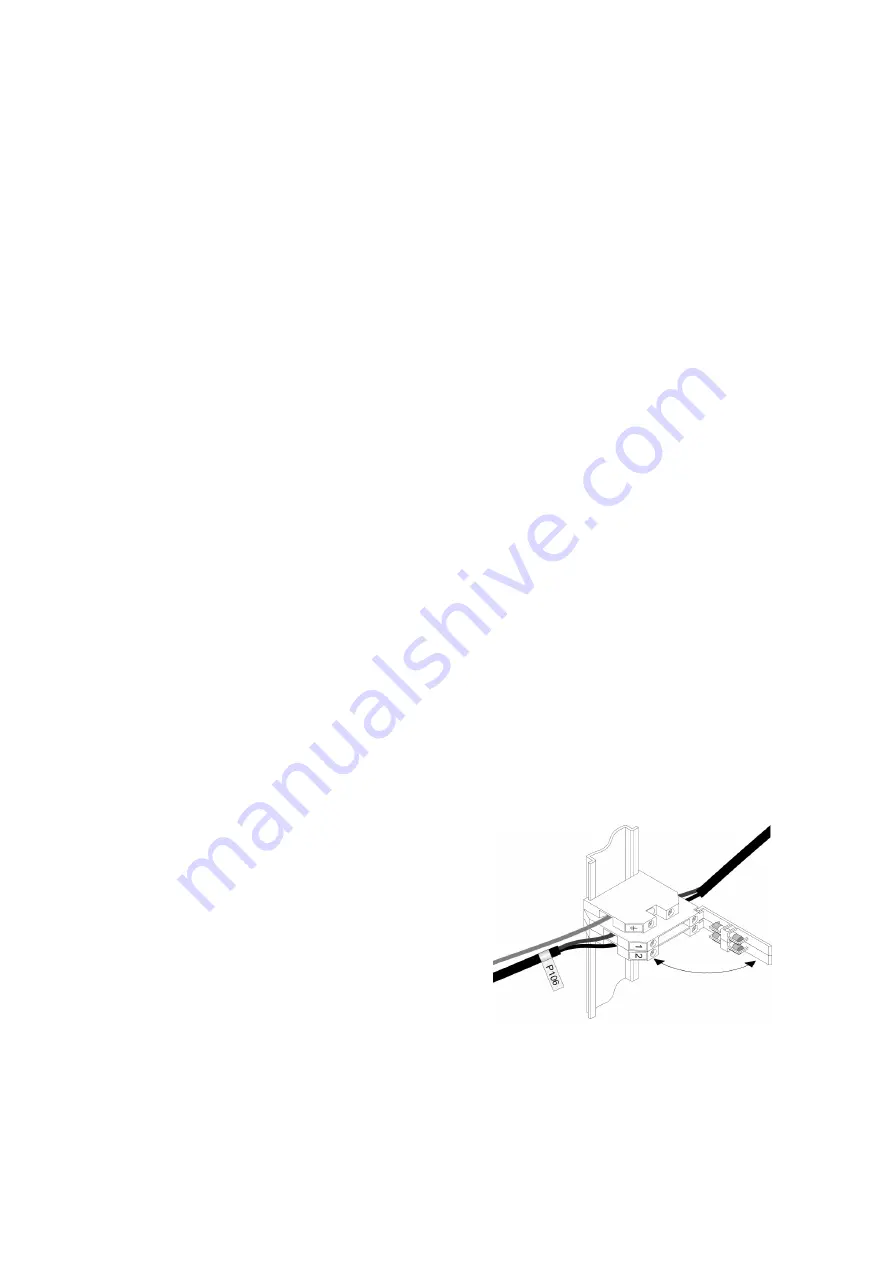

To comply with the requirements of EN 60079:14

Electrical installations design, selection and erection

,

each of the wires entering the hazardous area

should be individually fused and contain a means of

isolation. These two requirements may be satisfied

by using DIN rail mounted terminals incorporating

easily removable fuses which can be extracted to

achieve isolation as shown in Fig 2.

If an input current safety parameter Ii is specified, a

suitably rated fuse will ensure that it is not

continuously exceeded in normal operation.

Clear identification of, and easy access to the

means of isolation is essential for their effective use.

It is also necessary to ensure that the maintenance

procedure makes sure that unauthorised re-closure

of the switches does not occur.

It is not considered necessary to have a means of

isolation or electrical protection for the screen.

Fig 2 DIN rail mounting terminals incorporating a

fuse.

For some applications Ex nA instrumentation

energised by a current limited power supply or

instrument that can be switched off, is considered

adequate and to comply with the requirements of the

standard.