13

7. MAINTENANCE

7.1 Fault finding during commissioning

If

a

BA448CF-P

fails

to

function

during

commissioning the following procedure should be

followed:

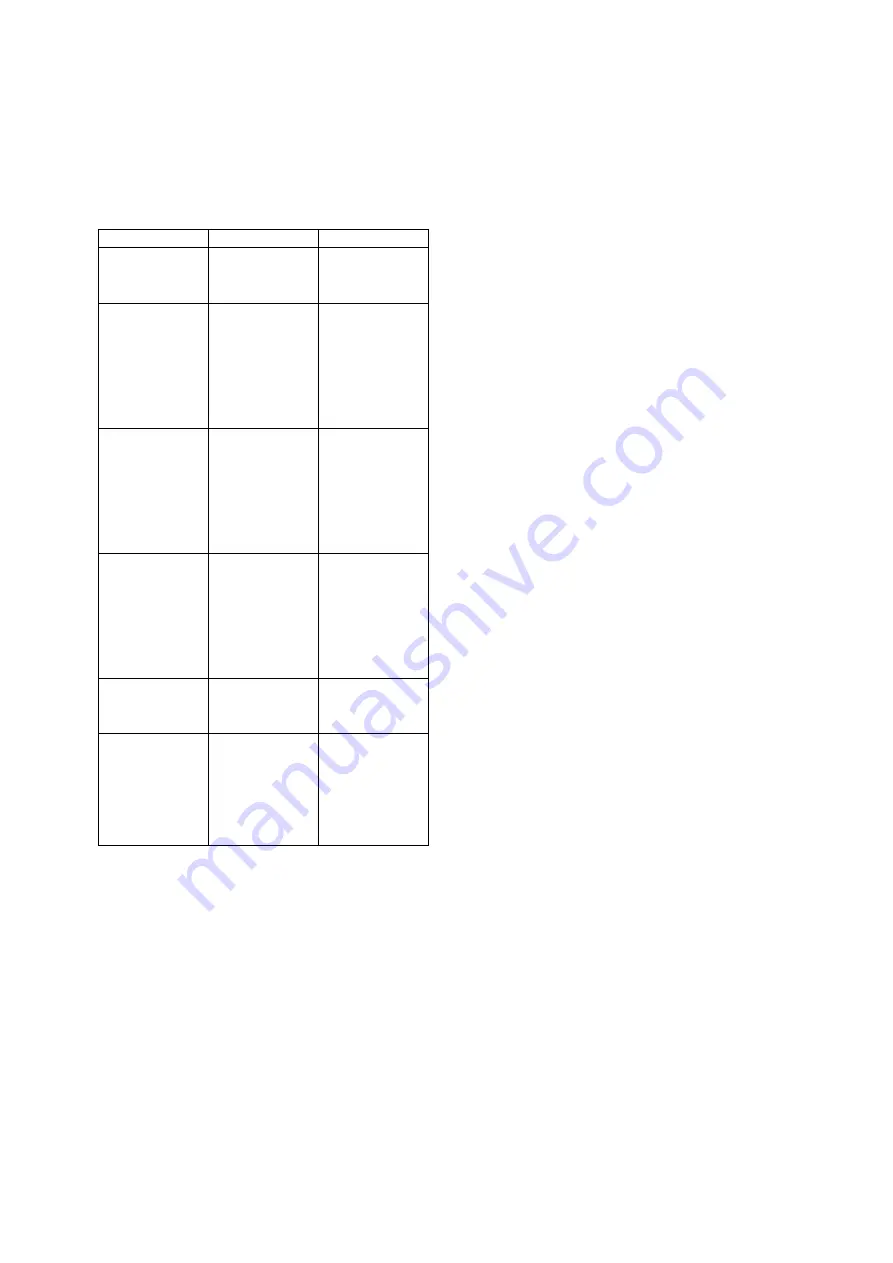

Symptom

Cause

Check:

No Display

Instrument not

correctly

connected or

powered.

9 to 22V between

terminals 1 & 2.

Display shows

‘9.9.9.9.9’ with all

decimal points

flashing; all

bargraph

segments

activated and

bargraph scale

flashing.

Value

over-range

Variable source

Decimal point

configuration.

Display shows

‘-9.9.9.9.9’ with

all decimal points

flashing; no

bargraph

segments

activated and

bargraph scale

flashing.

Value

under-range

Variable source

Decimal point

configuration

Display

alternates

between value

and the word

‘bAd’. Bargraph

flashes.

Status of fieldbus

variable has a

quality of ‘BAD’

or a fault state is

active.

Display has not

yet received

data.

Variable source

Fieldbus

configuration.

Bargraph scale

flashes.

Variable is

outside the limits

defined for the

bargraph.

Bargraph

configuration.

All display

segments

activated.

Display is

initialising.

This is normal

operation, after a

few seconds the

firmware version

will be displayed

prior to entering

the display

mode.

7.2 Fault finding after commissioning

ENSURE PLANT SAFETY BEFORE

STARTING MAINTENANCE

Live

maintenance

is

permitted

on

intrinsically safe equipment installed in a

hazardous area, but only certified test

equipment should be used unless a gas

clearance certificate is available.

If a BA448CF-P fails after it has been functioning

correctly, the table shown in section 7.1 may help

to identify the cause of the failure.

If this procedure does not reveal the cause of the

fault, it is recommended that the instrument is

replaced.

7.3 Servicing

We recommend that faulty BA448CF-P Fieldbus

Indicators be returned to BEKA associates or to

our local agent for repair.

7.4 Routine maintenance

The mechanical and electrical condition of the

instrument should be regularly checked. Initially

annual inspections are recommended, but the

inspection frequency should be adjusted to suit the

environmental conditions.

7.5 Guarantee

Instruments which fail within the guarantee period

should be returned to BEKA associates or our local

agent. It is helpful if a brief description of the fault

symptoms is provided.

7.6 Customer comments

BEKA associates is always pleased to receive

comments from customers about our products and

services. All communications are acknowledged

and

whenever

possible,

suggestions

are

implemented.