5

5. INSTALLATION

5.1 Location

The BA448CF-P is housed in a robust aluminium

enclosure with a toughened glass window mounted

in a Noryl bezel. The front of the instrument

provides IP66 protection and a gasket seals the

joint between the instrument enclosure and the

panel. The instrument may be installed in any

panel providing the environmental limits shown in

the specification are not exceeded.

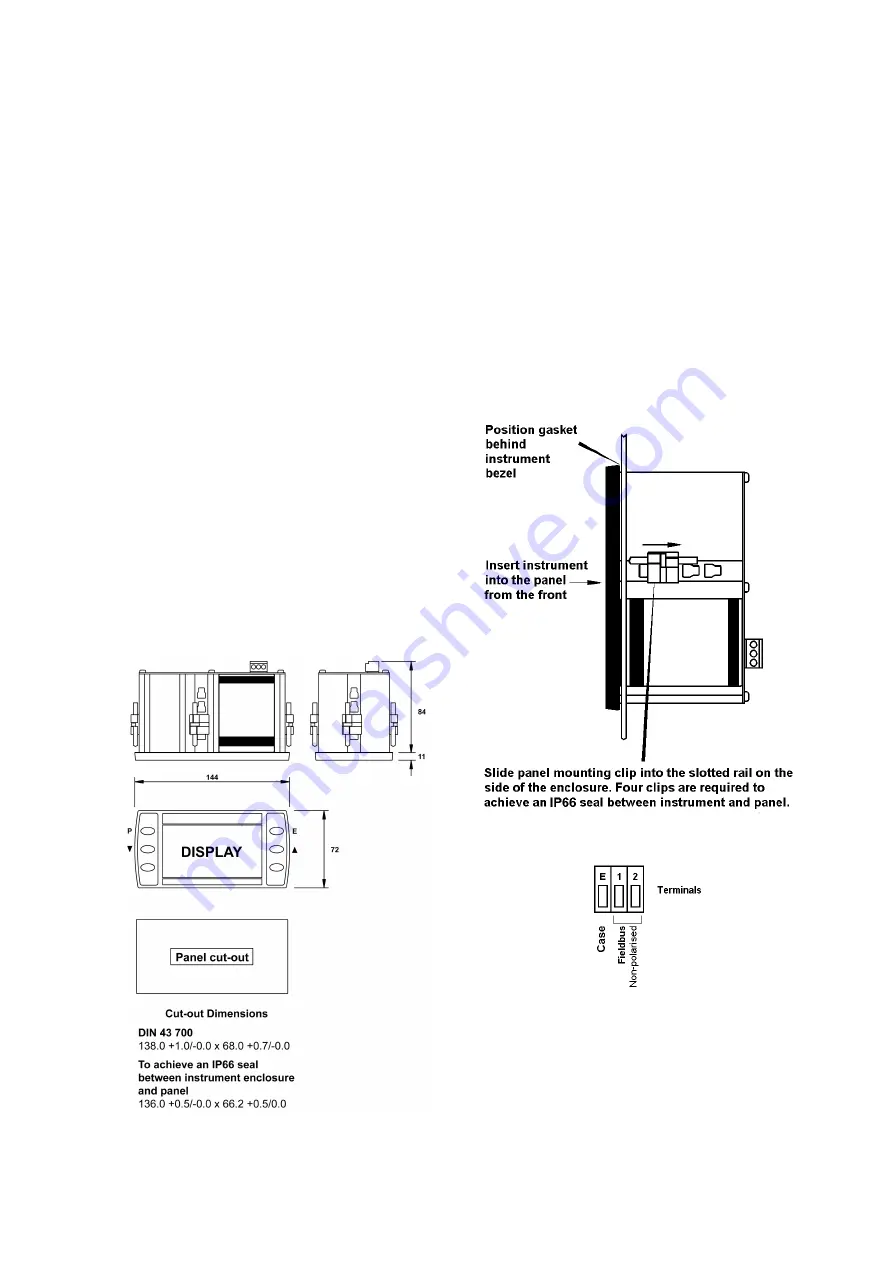

Fig 2 shows the overall dimensions of the

BA448CF-P and the panel cut-out. To achieve an

IP66 seal between the instrument enclosure and

the panel, the smaller cut-out must be used and

the instrument secured with four panel mounting

clips.

CAUTION

Installation in Zone 0

When installed in a Zone 0 potentially

explosive atmosphere requiring apparatus

of Category 1G, the indicator shall be

installed such that even in the event of rare

incidents, an ignition source due to impact

or friction between the aluminium enclosure

at the rear of the instrument mounting panel

and iron/steel is excluded.

Fig 2 BA448CF-P dimensions

5.2 Installation Procedure

a. Insert the BA448CF-P into the instrument

panel cut-out from the front of the panel.

b. Fix panel mounting clips to opposite sides of

the instrument and tighten until the

instrument is secure. Four clips are required

to achieve an IP66 seal between the

instrument enclosure and the panel.

c. Connect the panel wiring to the rear terminal

block as shown in Fig 3. To simplify

installation, the terminals are removable so

that panel wiring can be completed before

the instrument is installed.

Fig 3 Installation and terminal connections

5.3 EMC

The BA448CF-P complies with the requirements of

the European EMC Directive 2004/108/EEC. For

specified immunity, all wiring should be in

screened twisted pairs with the screens earthed at

one point in the safe area.