5

b.

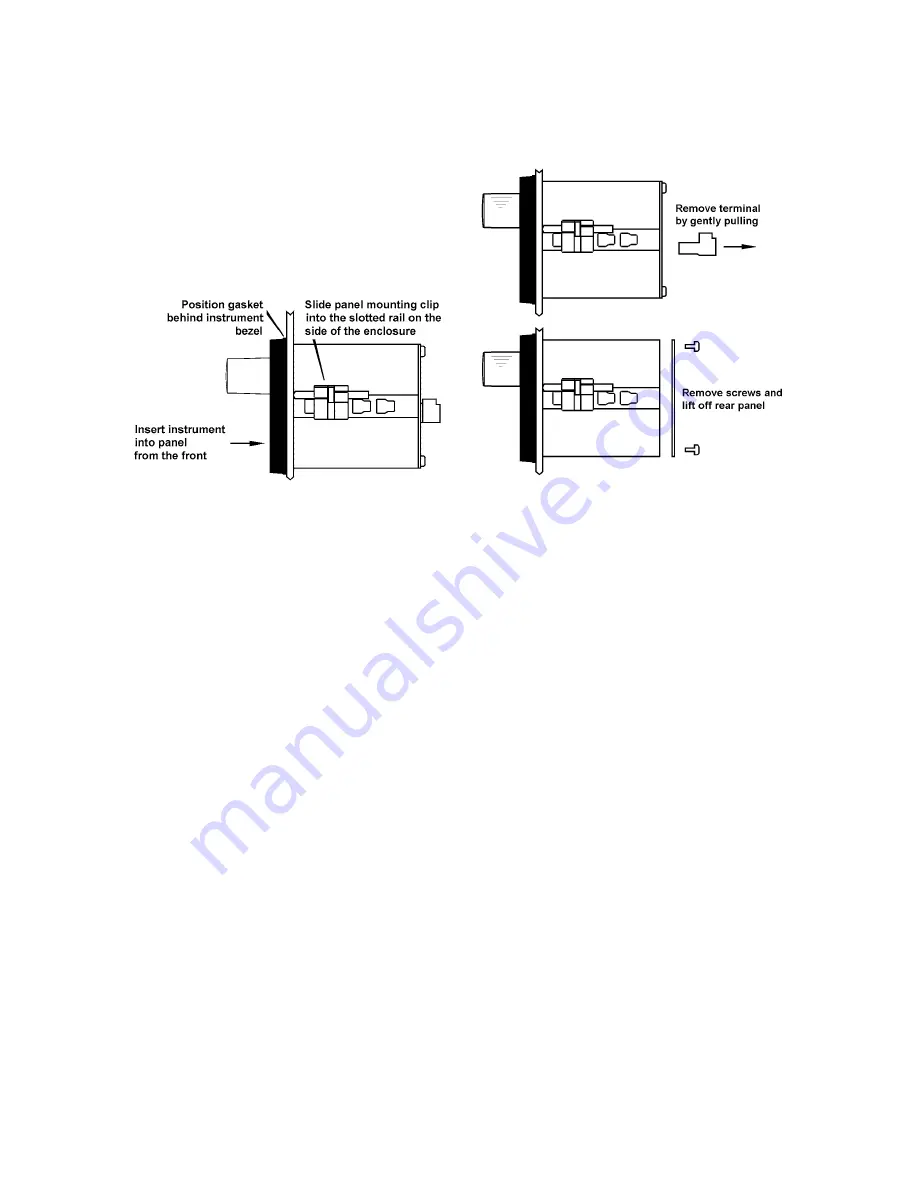

Fix two panel mounting clips to opposite

sides of the instrument and tighten until the

indicator is secured as shown in Fig 4.

c.

Connect the panel wiring to the rear terminal

block(s) as shown in Fig 3. To simplify

installation, the terminals are removable so

that the panel wiring can be completed

before the instrument is installed.

Fig 4 Fitting panel mounting clips

4.3 EMC

The BA505C complies with the requirements of

the European EMC Directive. For specified

immunity all wiring should be in screened twisted

pairs. The indicator enclosure may be earthed

locally by securing a tag under one of the rear

panel corner fixing screws.

5. Calibration

The front panel multi-turn control adjusts the set

point station’s output current between

approximately 3.5 and 21mA, no calibration is

required.

5.1 Internal display

The BA505C internal display may be calibrated so

that the 4/20mA loop current is shown in the

required engineering units.

The BA505C display will be supplied calibrated as

requested at time of ordering. If calibration is not

requested, the display will be set to show 00.0

with 4.000mA loop current, and 100.0 with

20.000mA loop current, but may easily be

recalibrated on-site.

The display is calibrated by plug-in links and two

multi-turn potentiometers that are accessible

through holes in the rear panel. To gain access

to the links the rear panel must be removed as

shown in Fig 5.

For maximum accuracy the display should be

calibrated using a traceable current measuring

device with an accuracy greater than 4µA.

Fig 5 Removal of rear panel

5.2 Zero adjustment

Zero is defined as the number displayed with a

4.000mA loop current, and may be adjusted

between -1000 and 1000. The zero

potentiometer has two ranges, 0 to 500 and 500 to

1000; the polarity of the zero is defined by the

position of the suppression / elevation links.

Fig 6 shows the position of the links and zero

potentiometer.

Suppression / elevation links

Elevation

Positive zero

0 to 1000

or

Suppression

Negative zero

0 to -1000

Zero link

0 to 500

or

500 to 1000

5.3 Span adjustment

Span is defined as the difference between the

number displayed at 4.000mA and the number

displayed at 20.000mA loop current. The span

potentiometer has four ranges defined by the span

links, and may be adjusted to any number

between 0 and 1999.

Fig 6 shows the position of the links and span

potentiometer.

Span links

000 to 500

or

500 to 1000

or

1000 to 1500

or

1500 to 1999