Summary of Contents for BEKOMAT 8

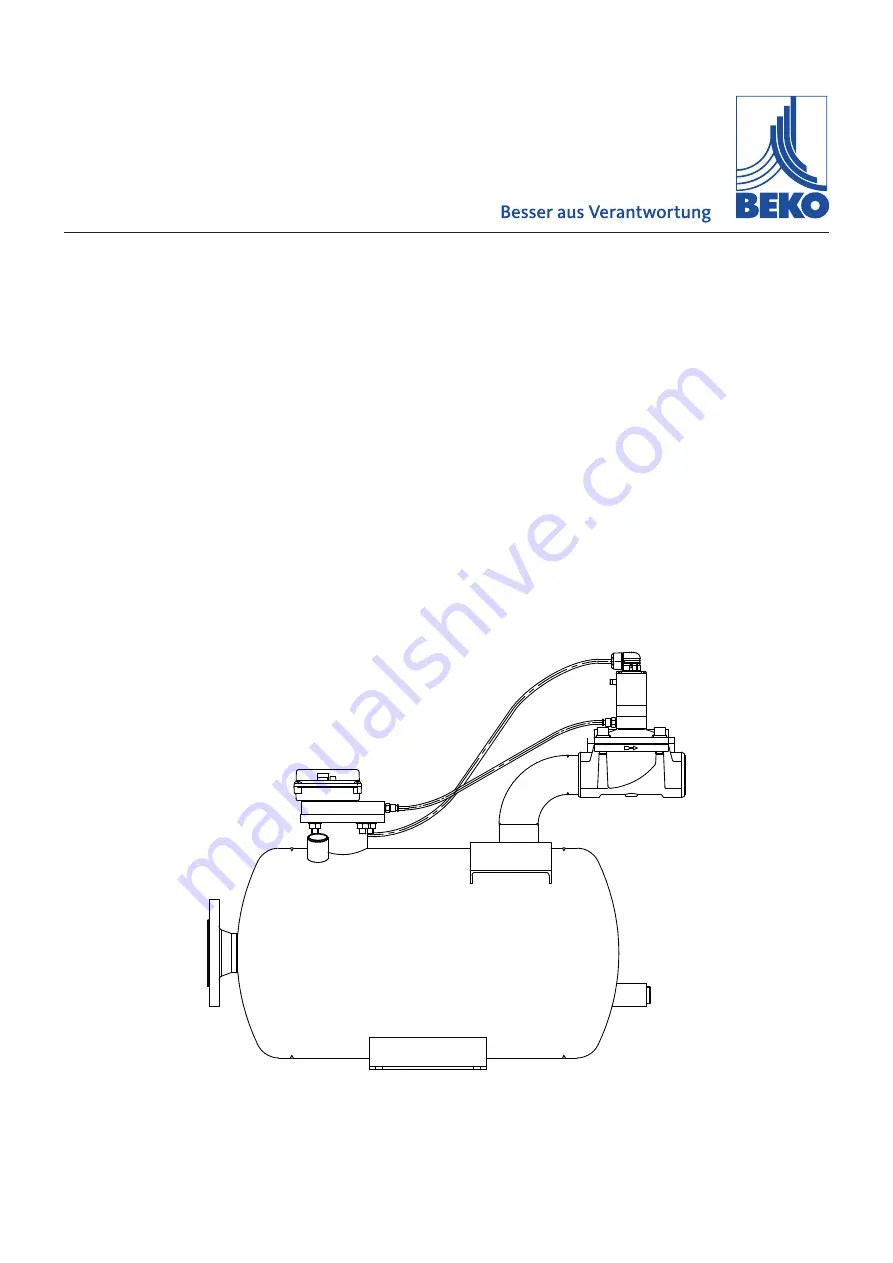

Page 1: ...BEKOMAT 8 BEKOMAT 9 EN English 01 3048 Condensate drain Installation and operating manual ...

Page 2: ...Installation and operating manual EN 2 BEKOMAT 8 9 ...

Page 24: ...Installation and operating manual EN 24 BEKOMAT 8 9 8 Declaration of Conformity ...

Page 26: ...Installation and operating manual EN 26 BEKOMAT 8 9 ...

Page 27: ...EN Installation and operating manual BEKOMAT 8 9 27 ...