33

Heatless Desiccant Dryers

|

Instruction Manual

Section 7:

Energy Management

Using a Standard Pressure Switch for Purge Control

Many compressors come equipped with pressure switches

with extra contacts that can be utilized to switch off the

dryer’s purge when the compressor is in an unloaded state.

Unfortunately, many of these switches have significantly large

dead bands (difference between the load (on) and unload (off)

settings that in most cases cannot be altered). The amount of

air that can pass downstream, through the dryer, while the

compressor is unloaded must be taken into consideration as

it can be significant, especially if there is a large dead band

and/or large wet receiver.

Often, a stand-alone pressure switch is a better option

as it allows the user to adjust it independently from the

compressor’s pressure switch. When selecting a stand-alone

pressure switch, the smaller the dead band the better.

When using a stand-alone pressure switch, the dryer is wired

into the normally closed contacts on the pressure switch.

When the switch is actuated (at 100 psig in the example), the

purge shuts off until the pressure switch deactuates (at 95

psig in example). The point at which the switch deactuates,

may be adjusted to suit the system.

If it is determined that the dew point drops to an

unacceptable level, the deactuation point must be increased.

Please note that with most standard pressure switches, the

dead band is fixed such that the activation and deactuation

points move together.

It is extremely important to understand that the purge may

only be shut off during periods of low or no demand. This

feature, if used otherwise, can result in permanent damage

to the desiccant beds resulting in loss of drying capacity

and possibly mechanical failure. The cartridges must not be

allowed to become fully saturated at any time.

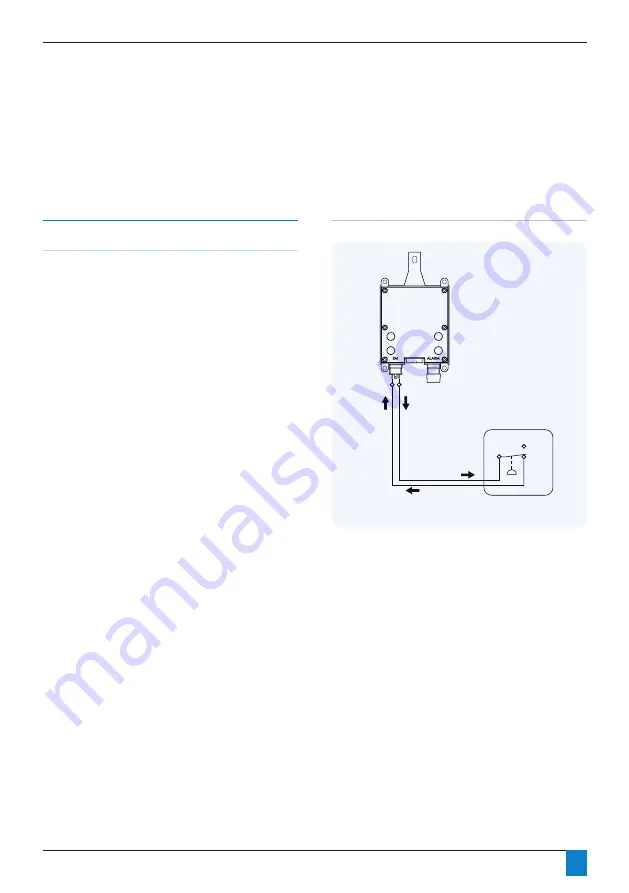

The following schematic offers an overview of the devices

mentioned as they might be connected for use in controlling

a dryer’s purge function. Please note that specific details

differ between device manufacturers, so in all cases the

manufacturer’s specifications should be adhered to.

Figure 7.2: Using a standard pressure switch for Purge Control.

(Puts out+5 VDC Signal)

PRESSURE SWITCH

(Field Installed)

N.C.

N.O.

DRYER

CONTROLLER

PIN 1

Signal Out

Signal Back

PIN 2

*

*

N

ormally

C

losed, open to turn purge off