8

Heatless Desiccant Dryers

|

Instruction Manual

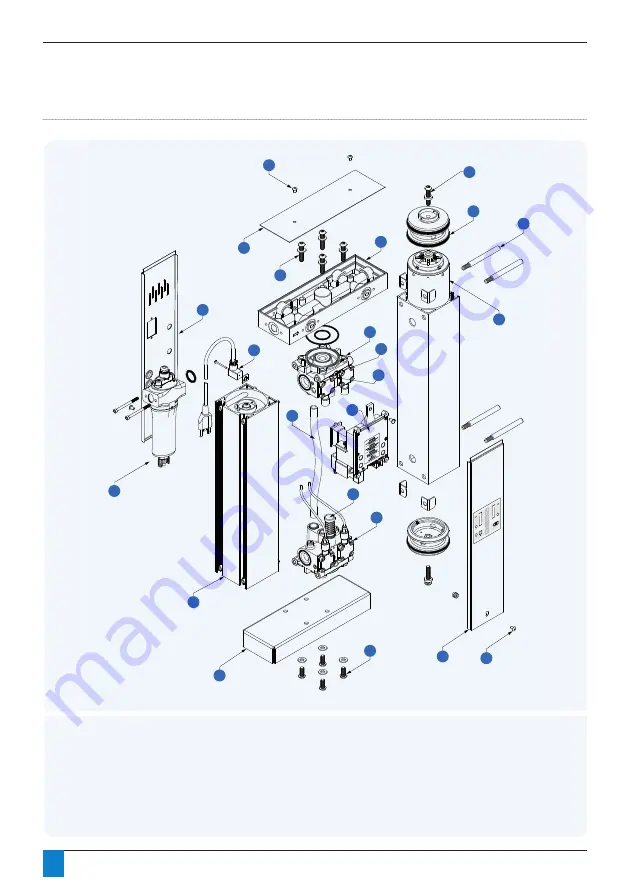

Figure 2.2: Models 4 SCFM – 35 SCFM

Section 2:

General Description

13

12

5

11

15

16

9

10

1

21

14

22

20

8

3

6

7

5

4

19

18

17

2

1. Top valve assembly

2. Control unit

3. Bottom valve assembly

4. Dryer base

5. Bottom valve fixing bolt

6. Front panel

7. Front panel fixing screw

8. Pressure housing

9. Pressure housing retaining bolt

10. Desiccant cartridge (comes with dust filter)

11. Multiport manifold

12. Top cover

13. Top cover fixing screw

14. Rear panel

15. Banjo fixing bolt

16. Pressure seal

17. Exhaust silencer

18. Purge plug

19. Purge plug fixing screw

20. Pre-filter

21. Power cord

22. Down tube