12

Heatless Desiccant Dryers

|

Instruction Manual

Technical notes

1.

Pre-filtration, including a Water Separator is essential to maintain dryer performance.

2.

An appropriate Water Separator must be installed. If bulk water enters the adsorption dryer it can cause heat expansion to the

desiccant, substantial rise in the dryer differential pressure, poor outlet dewpoint, potentially resulting in dryer failure.

3.

The manufacturer recommends fitting a reverse flow

0.01 micron dust filter

to the outlet.

4.

Call your nearest manufacturer sales team for further information.

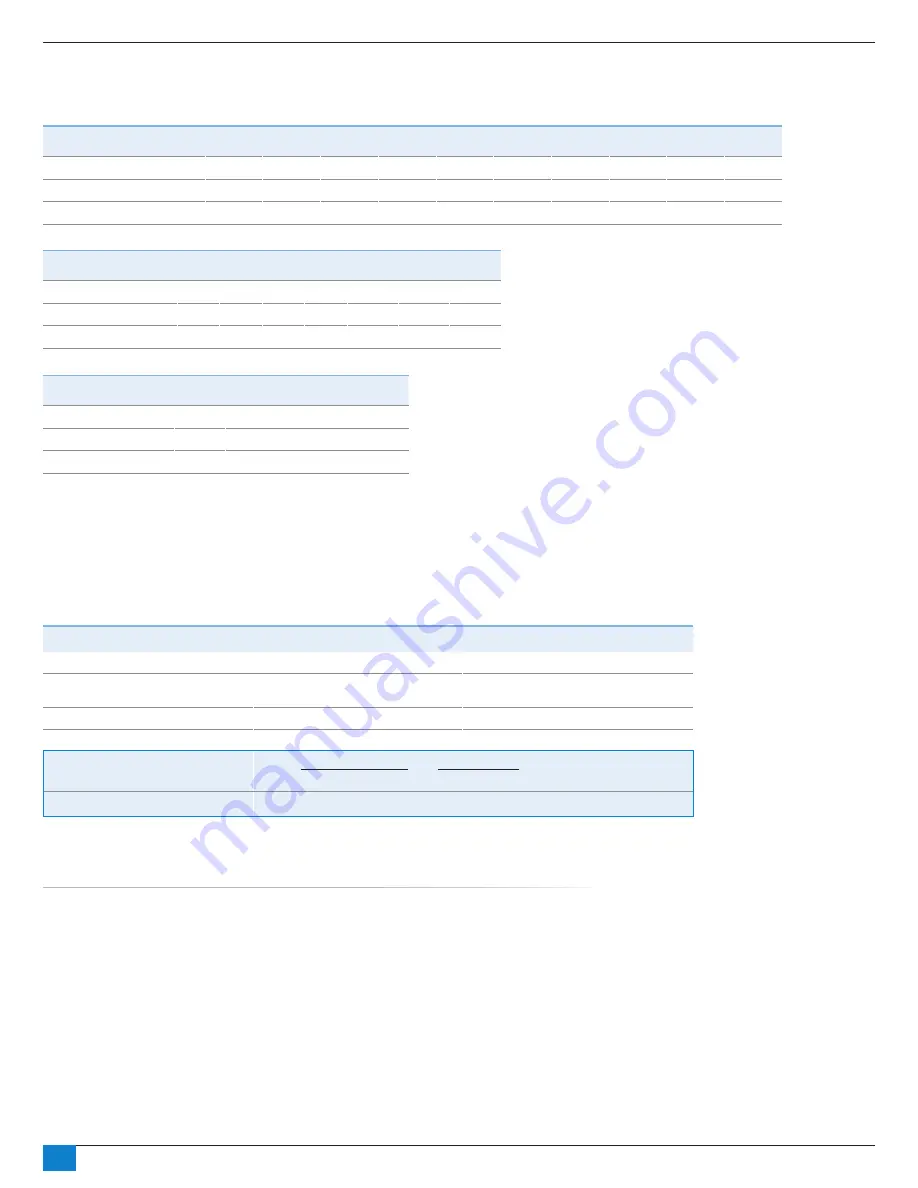

Operating pressure (PCF)

psig

58

72

87

100

115

130

145

160

174

189

barg

4

5

6

7

8

9

10

11

12

13

Correction factor

0.62

0.75

0.87

1.0

1.12

1.25

1.37

1.50

1.62

1.75

Temperature (TCF)

Farenheit °F

68

77

86

95

104

113

122

Celcius °C

20

25

30

35

40

45

50

Correction factor

1.3

1.2

1.1

1.0

0.75

0.65

0.45

Pressure dewpoint (DCF)

Farenheit °F

-4

-22

-40

-94*

-100*

Celcius °C

-20

-30

-40

-70

-74

Correction factor

1.23

1.2

1.0

0.8

0.77

Dryer correction factors

Section 3:

Technical Data

45 SCFM - 110 SCFM

To correctly select the dryer model suitable for your application the following information is required: Minimum Inlet Pressure, Maximum Inlet

Temperature, Maximum Compressor Inlet Flow and Required Pressure Dewpoint (PDP).

Requirements

Correction Factor

Maximum compressor inlet flow

56 scfm

-

Actual minimum inlet pressure

to the dryer

87 psig

PCF = 0.87

Maximum inlet temperature

77°F (25°C)

TCF = 1.2

Pressure dewpoint (PDP)

-100°F (-74°C)

DCF = 0.77

Corrected dryer flow rate

Appropriate Dryer Size

Dryer model is selected based on the corrected flow rate, i.e. 75 SCFM.

Inlet flow rate

PCF x TCF x DCF

56

(0.87 x 1.2 x 0.77)

69.7 scfm

(118 Nm³/hr)

=

=

Dryer Sizing Example

* Only achievable when utilizing High Performance cartridges