Technical description

20

DRYPOINT® RA HT 20-350 NA UL

11 Technical description

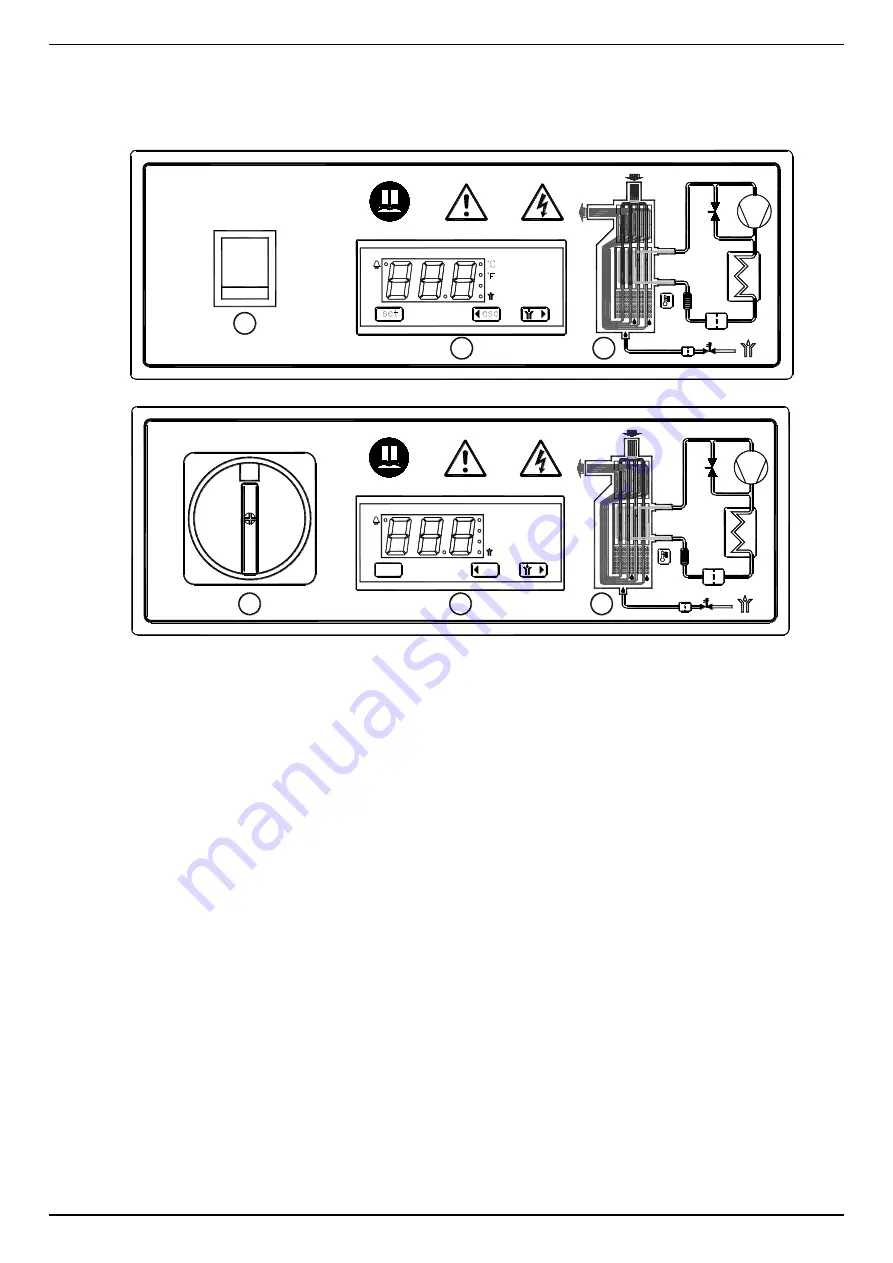

11.1 Control panel

The control panel explained below is the only dryer user interface.

DRYPOINT RA HT 20

– 100 NA UL

DRYPOINT RA HT 150

– 350 NA UL

1

2

3

ON-OFF Switch

Electronic instrument

Air and refrigerant flow diagram

11.2 Functional description

Operating principle

– The dryer models described in this manual all operate on the same principal. First the very hot

moisture laden air directly from the compressor enters the aftercooler (copper tube / aluminum fin cooling surface) where

it is cooled to within 18-20°F (10-12°C) of the ambient air temperature. It leaves the aftercooler with entrained condensed

water droplets which are separated by the 1 micron bulk liquid filter separator element and drained away by the first drain

system. The partially cooled moisture laden air next enters an air to air heat exchanger to pre-cool it. The compressed

air next goes through the evaporator, also known as the air to refrigerant heat exchanger. The compressed air

temperature is reduced to approximately 41°F (5°C), causing additional water vapor to condense to liquid. The liquid is

continuously coalesced and collected in the dryer separator for automatic removal by the second condensate drain. The

cool moisture free compressed air then passes back through the air to air heat exchanger to be reheated to within the

ambient temperature as it exits the dryer.

Refrigeration cycle

– Refrigerant gas is cycled through the compressor and exits at high pressure to a condenser where

heat is removed causing the refrigerant to condense to a high-pressure liquid state. The liquid is forced through a capillary

tube where the resulting pressure drop allows the refrigerant to boil off at a predetermined temperature. Low-pressure

liquid refrigerant enters the heat exchanger where heat from the incoming air is transferred causing the refrigerant to boil;

the resulting phase change produces a low pressure, low temperature gas. The low-pressure gas is returned to the

compressor, where it is re-compressed and begins the cycle again. During those periods when the compressed air load

is reduced the excess refrigerant is by-passed automatically back to the compressor via the Hot Gas By-pass Valve circuit.

K

1

2

3

PQS0003

DMC14

1

0

K

I

ON

1

3

set

DMC 14

°C

esc

°F

2

PQ

S

000

4

Summary of Contents for DRYPOINT RA HT 100-P NA UL

Page 19: ...DRYPOINT RA HT 20 350 NA UL 19 10 2 Technical data DRYPOINT RA HT 150 350 NA E 1 230 60 UL ...

Page 34: ...Appendices 34 DRYPOINT RA HT 20 350 NA UL 13 1 2 Dryers Dimensions DRYPOINT RA HT 75 NA UL ...

Page 35: ...Appendices DRYPOINT RA HT 20 350 NA UL 35 13 1 3 Dryer dimensions DRYPOINT RA HT 100 NA UL ...

Page 36: ...Appendices 36 DRYPOINT RA HT 20 350 NA UL 13 1 4 Dryer dimensions DRYPOINT RA HT 150 NA UL ...

Page 46: ...Appendices 46 DRYPOINT RA HT 20 350 NA UL 13 3 2 Electric diagram DRYPOINT RA HT 20 50 NA UL ...

Page 47: ...Appendices DRYPOINT RA HT 20 350 NA UL 47 13 3 3 Electric diagram DRYPOINT RA HT 75 100 NA UL ...

Page 48: ...Appendices 48 DRYPOINT RA HT 20 350 NA UL 13 3 4 Electric diagram DRYPOINT RA HT 150 NA UL ...

Page 51: ...Appendices ...