Technical description

DRYPOINT® RA HT 20-350 NA UL

25

11.15.5 How is controlled the drain solenoid valve

Drain solenoid valve is activated (ON) for

seconds (standard 2 seconds) every

minutes (standard 1 minute).

Led

shows that condensate drain solenoid valve is ON.

The condensate drain test is always active using the button

.

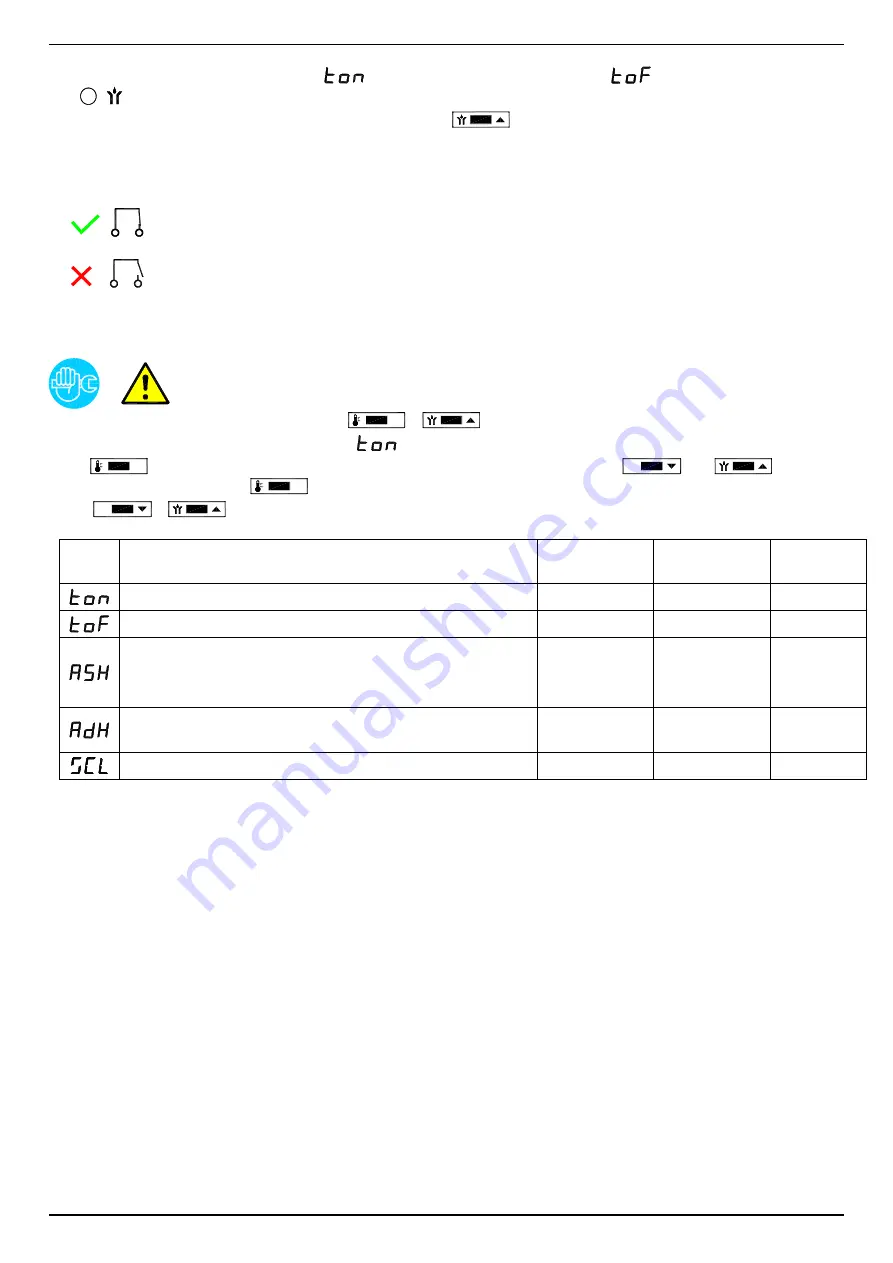

11.15.6 Operation of the failure / alarm dry contact

The DMC14 is equipped with a dry contact (potential free) to display failure and/or alarm conditions.

Dryer powered and no service warning / alarm is active.

Dryer not powered or service warning / alarm is active.

11.15.7 How to change the operating parameters

– SETUP menu

The setup menu can be used to change the

dryer’s operating parameters.

Only qualified personnel must be allowed to access to the setup menu. The manufacturer is not

responsible for malfunctioning or failure due to modification to the operating parameters.

With dryer ON simultaneously press buttons

+

for at least 3 seconds to enter the setup menu.

Access to the menu is confirmed by message

on the display (first parameter of menu).

Keep

pressed to display the value of the selected parameter and use arrows

and

to change

the value. Release the button

to confirm the value and skip to following parameter.

Press

+

to exit setup menu (if no button is pressed after 10 seconds the menu is exited automatically).

ID

Description

Limits

Resolution

Standard

setup

Ton

– drain time ON : time ON condensate drain valve

00 … 20 sec

1 sec

2

ToF - drain time OFF : pause time for condensate drain valve

1 … 20 min

1 min

1

ASH

– High DewPoint Setting : Alarm threshold for a high

DewPoint (the alarm disappears when the temperature drop

0.5°C / 1°F below alarm point)

0.0…25.0 °C

or

32 … 77 °F

0.5 °C

or

1 °F

20

or

68

AdH - High DewPoint Delay : high DewPoint alarm enable

delay

01 … 20

minutes

1 min

15

SCL - Scale: display scale of temperatures.

°C … °F

-

°C

11.16 Electronic level controlled condensate drain BEKOMAT

The electronic level controlled drain BEKOMAT has a special condensate management that makes sure that condensate

is drained safely without any unnecessary air-loss. This drain consists of a condensate accumulator where a capacitive

sensor continuously checking liquid level is placed: as soon as the accumulator is filled, the sensor passes a signal to

the electronic control and a diaphragm solenoid valve will open to discharge the condensate. Right in time the discharge

line will be closed again without wasting compressed air.

ATTENTION!

These BEKOMAT condensate drains have been specially designed for the use in a refrigerant dryer

DRYPOINT RA HT

NA

. Any Installation in other compressed air treatment units or the exchange against a different drain brand may lead to

malfunction. Do not exceed the max. operating pressure (see type plate)!

Make sure when the dryer starts the upstream valve is open.

NOTE:

For detailed information on drainer functions, troubleshooting, service and replacement parts, please refer to

the BEKOMAT drainer manual.

8

9

8

9

Set

Set

Set

Summary of Contents for DRYPOINT RA HT 100-P NA UL

Page 19: ...DRYPOINT RA HT 20 350 NA UL 19 10 2 Technical data DRYPOINT RA HT 150 350 NA E 1 230 60 UL ...

Page 34: ...Appendices 34 DRYPOINT RA HT 20 350 NA UL 13 1 2 Dryers Dimensions DRYPOINT RA HT 75 NA UL ...

Page 35: ...Appendices DRYPOINT RA HT 20 350 NA UL 35 13 1 3 Dryer dimensions DRYPOINT RA HT 100 NA UL ...

Page 36: ...Appendices 36 DRYPOINT RA HT 20 350 NA UL 13 1 4 Dryer dimensions DRYPOINT RA HT 150 NA UL ...

Page 46: ...Appendices 46 DRYPOINT RA HT 20 350 NA UL 13 3 2 Electric diagram DRYPOINT RA HT 20 50 NA UL ...

Page 47: ...Appendices DRYPOINT RA HT 20 350 NA UL 47 13 3 3 Electric diagram DRYPOINT RA HT 75 100 NA UL ...

Page 48: ...Appendices 48 DRYPOINT RA HT 20 350 NA UL 13 3 4 Electric diagram DRYPOINT RA HT 150 NA UL ...

Page 51: ...Appendices ...