DURABLASTER

®

WHEEL CLEANER

30

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL054

Maintenance

Disassembly Procedure

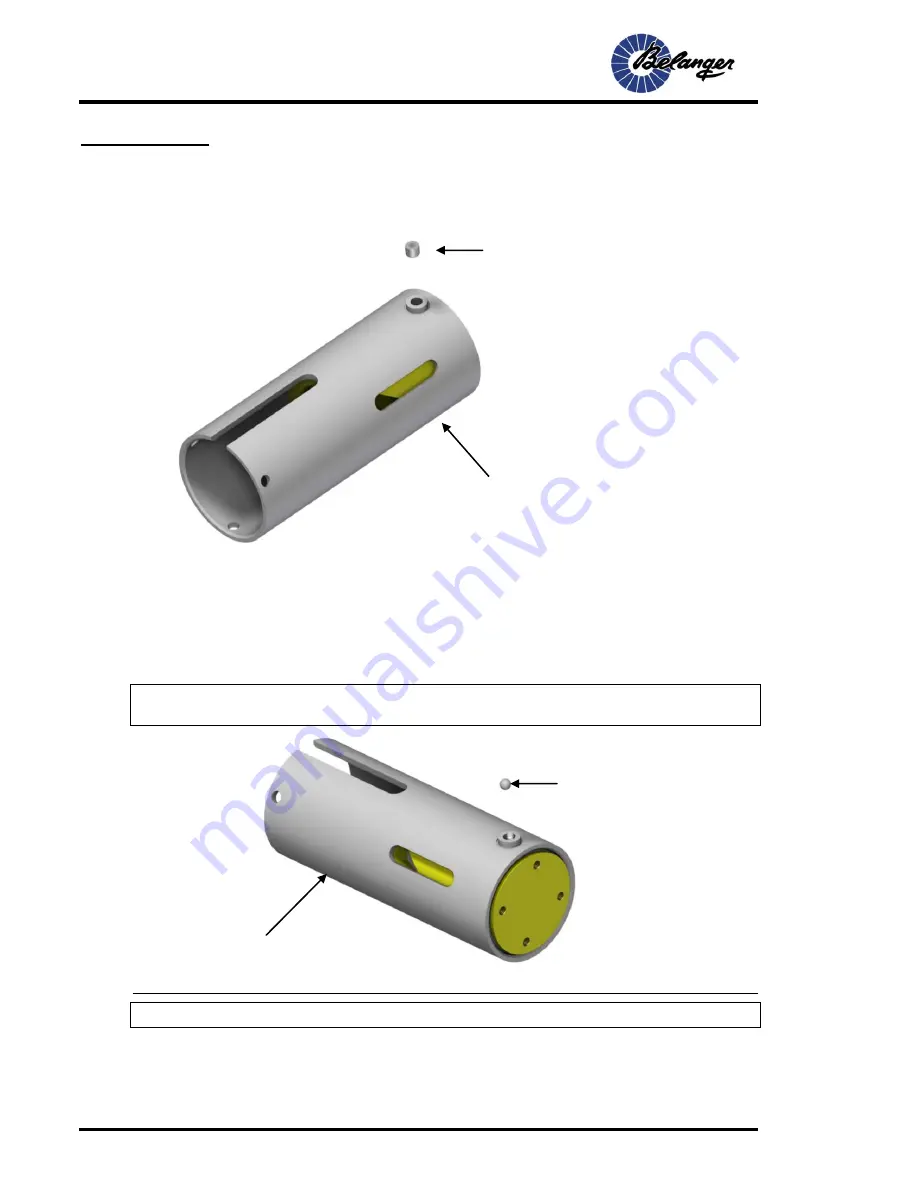

7. The first step in removing the piston from the tube assembly is to remove the plug. See the

image below: Set the plug aside until reassembly.

8. The second step in removing the piston from the tube assembly is to remove the (30) ball

bearings. To remove the ball bearings:

Locate a cylindrical magnet that is 3/8” diameter or smaller (Belanger® part number

1ELECT-SW890).

Put the magnet into the hole that had the plug in it and pull out the ball bearings one

by one.

Note:

Thread the 5/16” fasteners removed in step 2 into the piston and rotate the piston, as

needed, until all (30) ball bearings have been removed.

Note:

During Reassembly, when reinstalling the ball bearings:

Use a Marine Grade Grease

Apply approximately 3 pumps of grease from a grease gun

Tube Assembly

Plug

Ball Bearing

Tube Assembly