DURABLASTER

®

WHEEL CLEANER

36

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL054

Maintenance

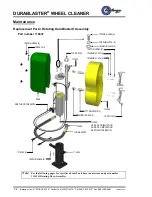

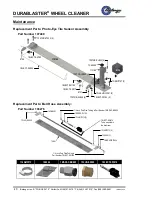

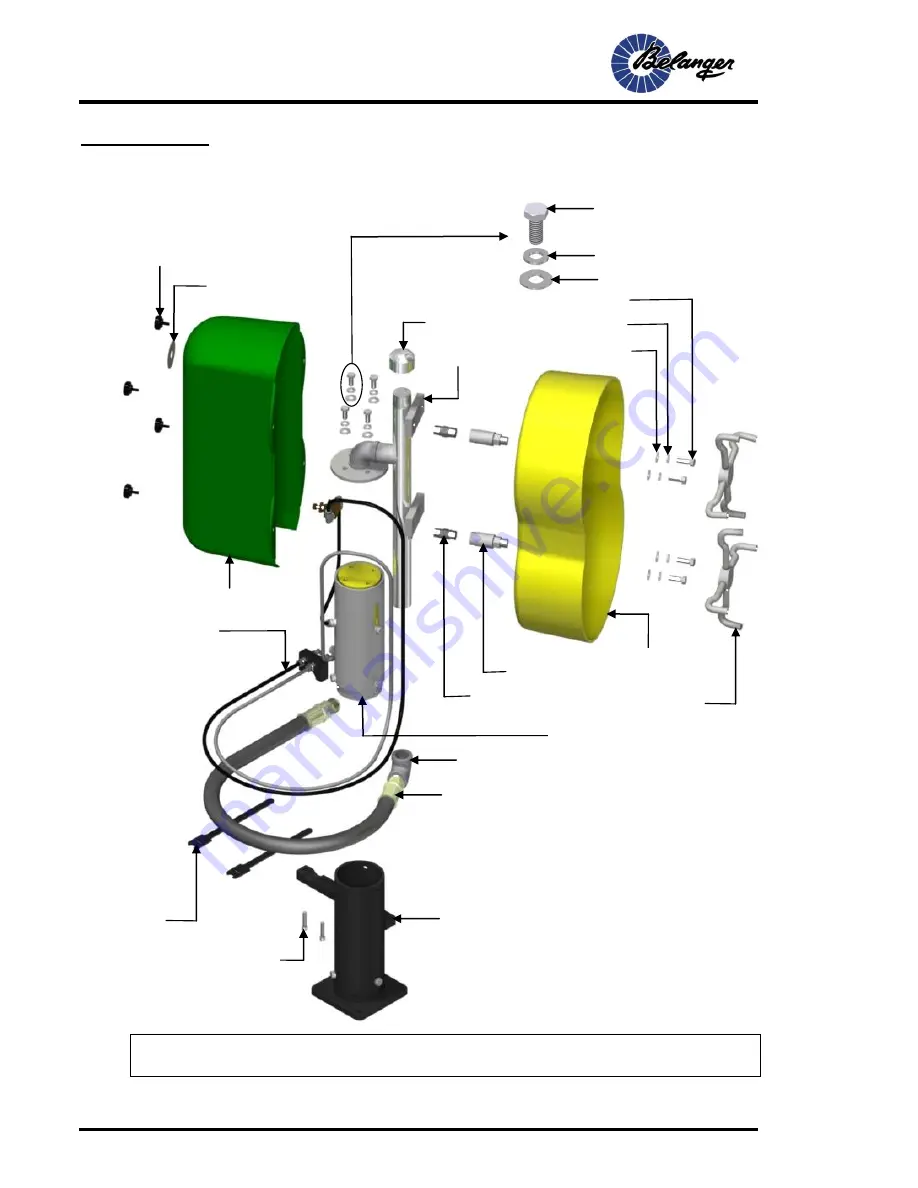

Replacement Parts: Rotating DuraBlaster® Assembly

Part number 110437

Note:

See the following pages for specifics about the air hose connections and part number

110436 (Rotating Base Assembly).

1FSTNR-HK200 (4)

1DECAL013

1FSTNR-HH165 (4)

1WASHR-LC270 (4)

1WASHR-FL415 (4)

1CAP-SS100

110432

1WASHR-FL415 (4)

1WASHR-LC270 (4)

1FSTNR-HH180 (4)

110432

1NIPPL-SS048 (2)

1FTTNG-SW515 (2)

110438

1ROTO125 (2)

9395

1HOSE-HY028

1TIE190 (2)

110436

HAS A PS ORIENTATION

AND A DS ORIENTATION

SEE THE NOTE BELOW

1FSTNR-SH406 (2)

110433

SEE THE NOTE BELOW