FLIPPING™ ARCH

1MANUL027

Belanger®, Inc. *PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

21

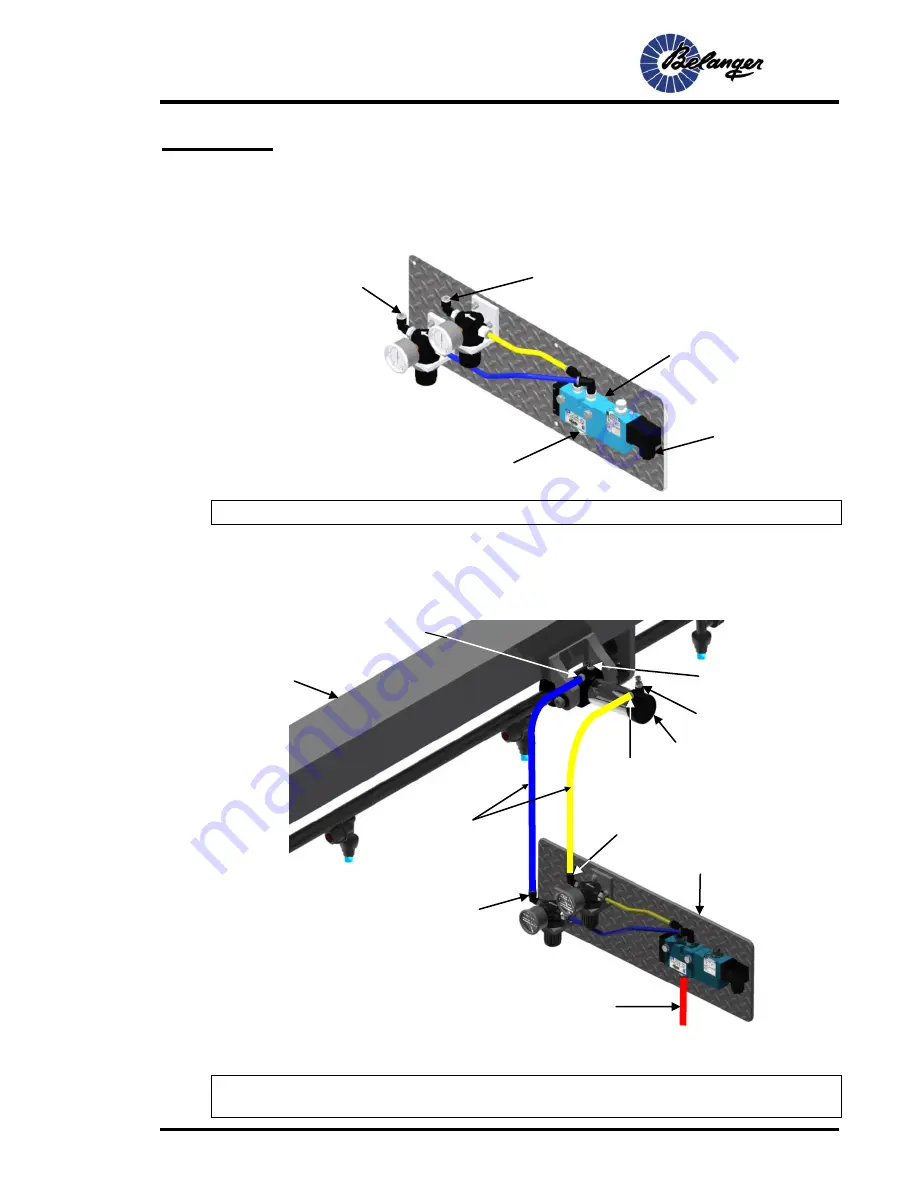

Installation

Utility Connections

Air

1. Locate the air panel in a dry location. See the image below.

Note:

The 4-Way Air Valve requires a 120VAC program function from the site controller.

2.

Run a 1/4” Poly-Flow air line from the main air supply to the Main Air Connection on the air

panel. See the images above and below.

3.

Run a 1/4” Poly-Flow air line from the extend regulator on the air panel to the extend port on

the Cylinder. See the images above and below.

4.

Run a 1/4” Poly-Flow air line from the retract regulator on the air panel to the retract port on

the Cylinder. See the images above.

Note:

Each port on the Cylinder has flow controls to adjust the cylinder actuation speed. See the

image above.

Extend Regulator Connection

1/4” Poly-Flow Tube to the Extend

Port on the Cylinder

Retract Regulator Connection

1/4” Poly-Flow Tube to the Retract

Port on the Cylinder

120 VAC Output from

the Site Controller

Retract Port

Speed Control for the Retract

Port on the Cylinder

Cylinder

Extend Port

Speed Control for the Extend

Port on the Cylinder

Head Assembly

4-Way Air Valve

Field Supplied 1/4" Poly Flow Tube

from the Main Pneumatic Source

@100 psi Air Flow Minimum

Field Supplied

1/4" Poly Flow Tube

Route as necessary

Air Panel

Extend Port

Retract Port

Main Air Connection

1/4” Poly-Flow Tube