Belarus 1025/1025.2/1025.3

Section G. Scheduled maintenance

G 41

Operation 44. Checking state of the

braking system.

1. Remove brakes’ housings together

with pressure and friction disks.

2. Clean inside housing cavities off

wear products; replace housings if

wear is large and there are cracks.

3. Check condition of clamping springs,

pressure disks, connecting rods and

profile grooves (hollows):

•

If springs are loose and there is

clearance between grips, replace

springs for new ones;

•

If profile grooves are worn out, replace

pressure disks;

•

If balls are corroded, replace them;

•

If working surfaces of pressure disks

have cracks, wear, circular grooves

and other defects, replace disks;

•

During subsequent assembly of

pressure disks grease balls and

hollows with thin coating of

consistent grease LITOL-24.

4. Check condition of friction disks:

•

If disks thickness is less than 6 mm ,

replace them;

•

If friction lining has cracks, flaking,

deep circular grooves and “glassing” ,

replace braking disks;

•

During subsequent assembly of

braking disks suitable for operation,

wash them in pure gasoline and polish

operation surfaces with abrasive

paper.

5. Adjust assembled brakes in

accordance with recommendations set

forth in operation manuals.

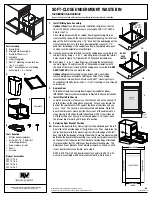

OPERATION 45. Tightening of bolts of

cylinder block head

.

NOTE!

Perform this operation only on

heated diesel.

Remove rockers’ cover, cover of

cylinder head and rockers’ axle in

assembly.

Using torque wrench, check and

tighten head bolts following sequence

shown in the figure to the right. Bolts’

torque should be within 160... 180

N

•

m (16... 18 kgf

•

m).

IMPORTANT!

After this operation check

clearances in valves and make

adjustment, if necessary.

Summary of Contents for 1025 2008

Page 205: ......