1523.5-0000010 OM

124

12. If necessary, limit the RLL height of the extreme upper position while the implement

uplifting. It is required for the slope angle decrease, for exclusion of cardan shaft touching

and damaging, and for providing safety clearance between the tractor and the implement.

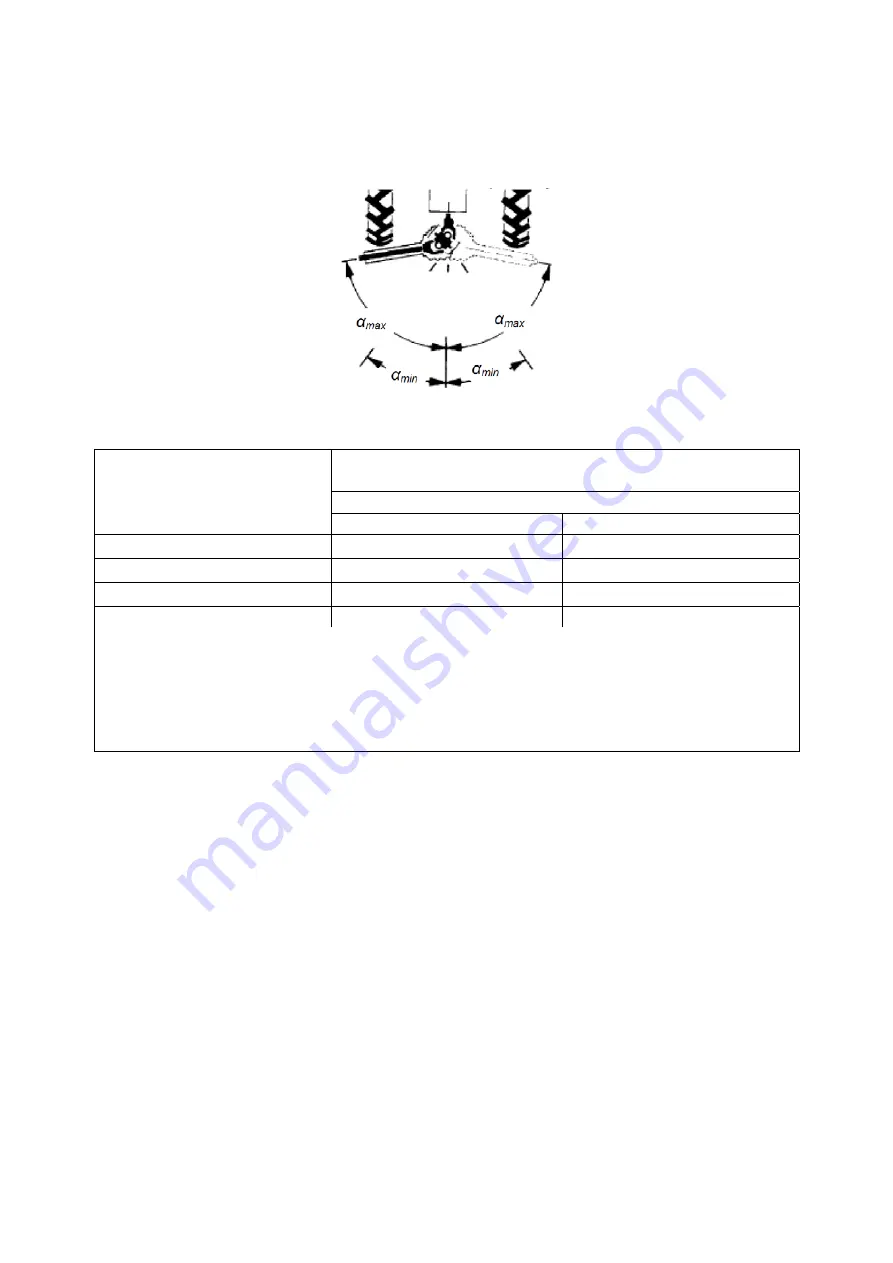

13. Maximum permissible slope and turning angles (figure 4.9.5) of the cardan shaft hinge

joints are shown in table 4.9.

Figure 4.9.5 – Maximum permissible slope and turning angles of the cardan shaft hinge

joints

Table 4.9

Tractor power take-off shaft

position

Maximum permissible angle of slope (turning)

α

max

1)

,

In degrees

Cardan shaft hinge joints type

Universal Equivalent angular rates

“On” position:

- under load

20

25

- no-load

2)

50

50

“ Off” position

3)

50

50

_________________________________

1)

Other variants are possible (see the documentation of cardan shaft and implement

manufacturers).

2)

For short period, for the PTO shaft operating with no load.

3)

For the implement transport position when the PTO shaft is off.

14. While operating with mounted and semi-mounted implements having cardan drive, it is

required to block the lift linkage lower links.

15. After the cardan shaft dismounting, it is required to put guard hoods on the PTO shaft

end extensions and PRS!

16. After the PTO shaft deactivation, consider the hazard of the implement cardan shaft

and separate mechanisms coupled coasting. For this reason the dangerous area between

the tractor and the implement can be entered only after the PTO shaft complete stop!

17. Check the operation of the implement with the cardan shaft mounted to the PTO shaft

and PRS at the minimum and maximum rpm of the tractor engine shaft.

18. While tractor transportation with trailed, semi-trailed and semi-mounted implements for

long distances, including from one field to another, it is recommended to disconnect the

cardan shaft from the tractor and from the implement.

19. Maintenance, cleaning and repair services of the implement with the cardan drive cou-

pled to the tractor shall be carried out only when the PTO shaft and the tractor engine are

off.

The PTO shaft shall be disengaged in the following cases:

- after the tractor stop, only after the coupled implement fully completed its duty cycle;

- on turns, when the implement is lifted to the transport position;