1523.5-0000010 OM

158

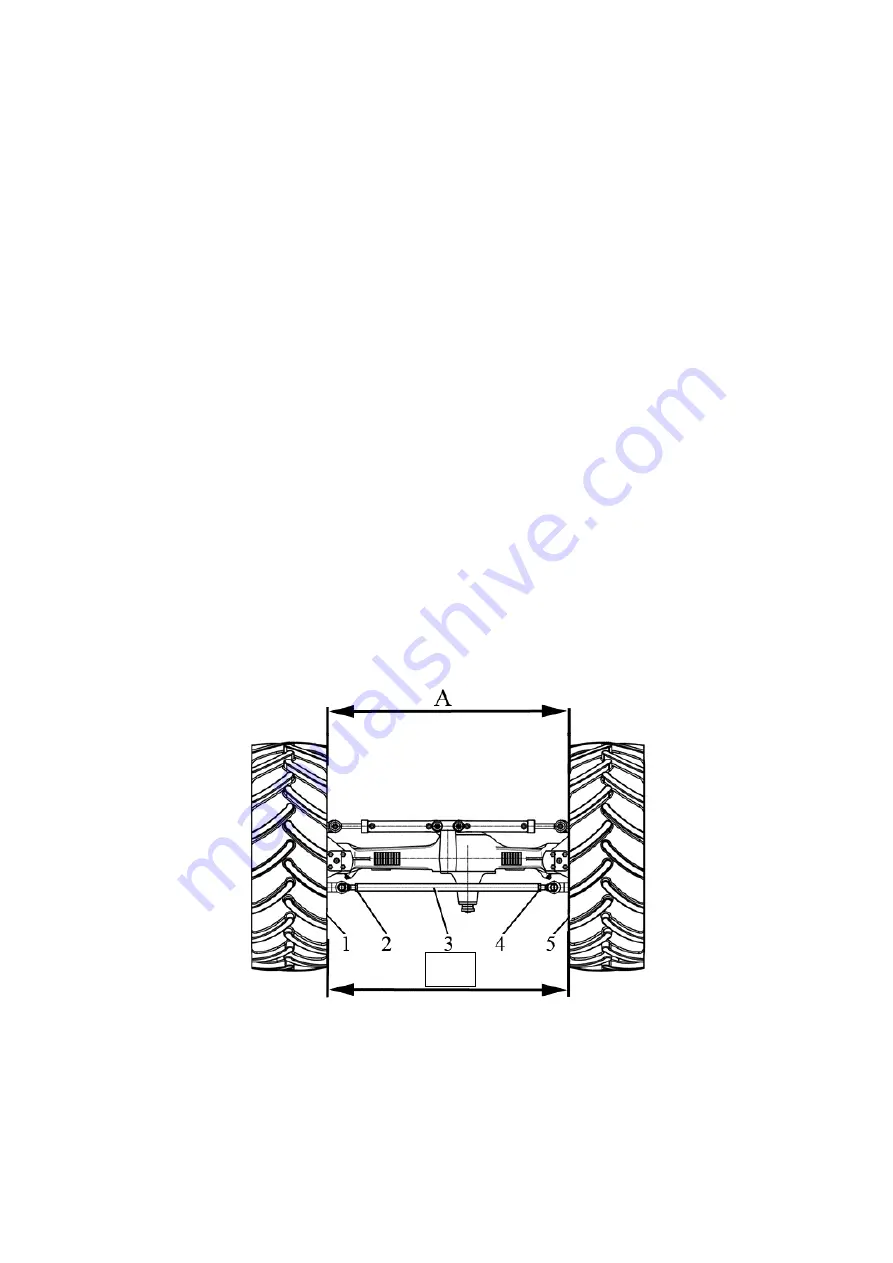

5.4.3.3 Operation 34. Check / adjustment of wheel toe-in

Adjustment of front wheel toe-in is carried out to prevent front tires from premature break-

down.

ATTENTION: CHECK AND ADJUSTMENT OF FRONT WHEEL TOE-IN SHALL BE

CARRIED OUT EVERY 250 HOURS OF TRACTOR OPERATION, AND AFTER EACH

TIME THE FRONT WHEEL TRACK WIDTH IS CHANGED. BEFORE CHECKING FRONT

WHEEL TOE-IN, CHECK AND ADJUST IF NECESSARY, THE STEERING JOINT

CLEARANCES!

To make necessary adjustments, do the following:

1. Make sure there are no clearance gaps in hinges of the steering mechanism, of the piv-

ot supporting block bearings and wheels.

2. Set front wheels into straight position corresponding to the direct tractor movement for

which drive the tractor on hard flat surface for not less than 3 meters and stop. Engage the

parking brake to avoid tractor movement.

3. Measure distance “

А

” (figure 5.4.20) between rim edges of front wheels 1 and 5 (figure

5.4.20) at the height of front wheel centers, and make visible marks in the measured plac-

es.

4. Disengage the parking brake, drive the tractor forward so that front wheels turn by half

revolution and measure distance “B” between wheel rim edges at the height of wheel cen-

ters at the back in the marked points.

5. If the value (“B”-“

А

”) is within 0 to 8 mm that means the toe-in is correctly adjusted. If the

value (“B”-“

А

”) is lower 0 or more than 8 mm, do the following:

а

) leaving the tractor position unchanged, unscrew lock nuts 2 and 4;

b) rotating steering link tube 3, try to get the value (“B”-“

А

”) within 0 to 8 mm;

c) repeat the operations described in subclauses 4 and 5.

d) if the value (“B”-“

А

”) is within the limits from 0 to 8 mm, tighten steering link lock nuts 2

and 4 with torque from 100 to 140 Nm, leaving the steering link length unchanged.

1, 5 – rim edge of front wheel; 2, 4 – locking nuts; 3 – adjustable tube.

Figure 5.4.20 – Diagram of front wheels toe-in adjustment

B