1523.5-0000010 OM

181

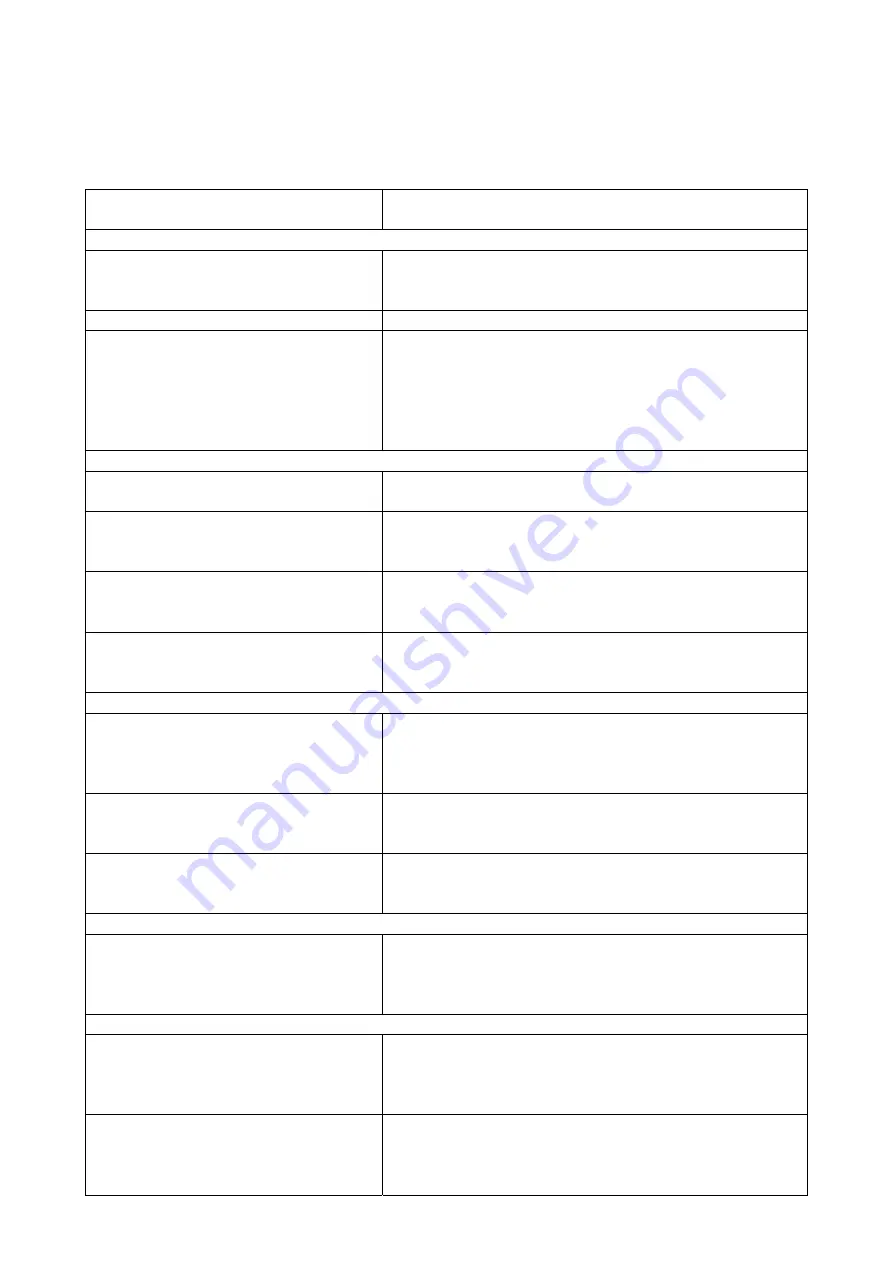

6.5 Possible failures in rear power take-off shaft and instructions for their trouble-

shooting

The list of possible failures of rear power take-off shaft and instructions for their trouble-

shooting are shown in Table 6.5.

Table 6.5

Failure, external manifestation,

cause

Troubleshooting

Rear PTO shaft end extension fails to rotate while activation

PTO mode shifting handle is not en-

gaged in the independent drive posi-

tion

Check and shift the handle in upper position

Improper adjustment of valve control Adjust valve control

There is no oil pressure at valve in-

put or at valve output to PTO fric-

tion coupling

Check pressure at control valve input, in case there

is no pressure correct the failure of the transmission

hydraulic system. In case there is no pressure at

valve output to PTO friction coupling - replace the

control valve

Rear PTO shaft fails to transmit full torque (“skidding")

Improper adjustment of valve control Adjust valve control

Low oil pressure in the transmission

hydraulic system

Adjust pressure reducing valve of the transmission

hydraulic system or correct other failures in the

transmission hydraulic system

Low oil pressure at valve output to

PTO friction coupling due to exces-

sive internal leakage

Check oil pressure running to PTO friction coupling,

replace friction coupling O-rings, if necessary

Friction coupling operation failure

due to piston deadlock or wear and

tear of frictional disks

Rinse friction coupling components in pure diesel

fuel, replace frictional disks, if necessary

While the PTO brake engagement, the shaft end extension goes on rotating

There is no oil pressure at valve in-

put or at the output to the PTO

brake

Check pressure at control valve input, in case there

is no pressure – eliminate the transmission hydraulic

system failures. In case there is no pressure at valve

output to the PTO brake - replace the control valve

Low oil pressure at the output to the

PTO brake due to excessive internal

leakage

Check oil pressure running to the PTO brake, replace

brake piston O-rings, if necessary

Brake operation failure due to piston

deadlock or wear and tear of fric-

tional disks

Rinse brake components in pure diesel fuel, replace

frictional disks, if necessary

Bent fracture of the PTO shaft end extension

Heavy bending load on the shaft

end extension from the coupled im-

plement drive (out-of-limit angles of

cardan shaft and etc.)

Eliminate breaks of coupling requirements. Correct

failures in the machine, replace the PTO shaft end

extension

Twisting of splines (teeth) of the PTO shaft end extension

Impact load generated by coupled

implement, that is transmitted to the

PTO shaft end extension

Check availability and operability of safety elements

of the coupled implement (torque-limiting clutch,

shear bolt) and eliminate the failure, replace the PTO

shaft end extension

Application of the PTO shaft end

type having unsuitable horsepower

capacity for the coupled implement

drive

Install the PTO shaft end of corresponding horse-

power capacity required by the implement drive (from

the set supplied with SPTA)