1523.6-0000010 OM

87

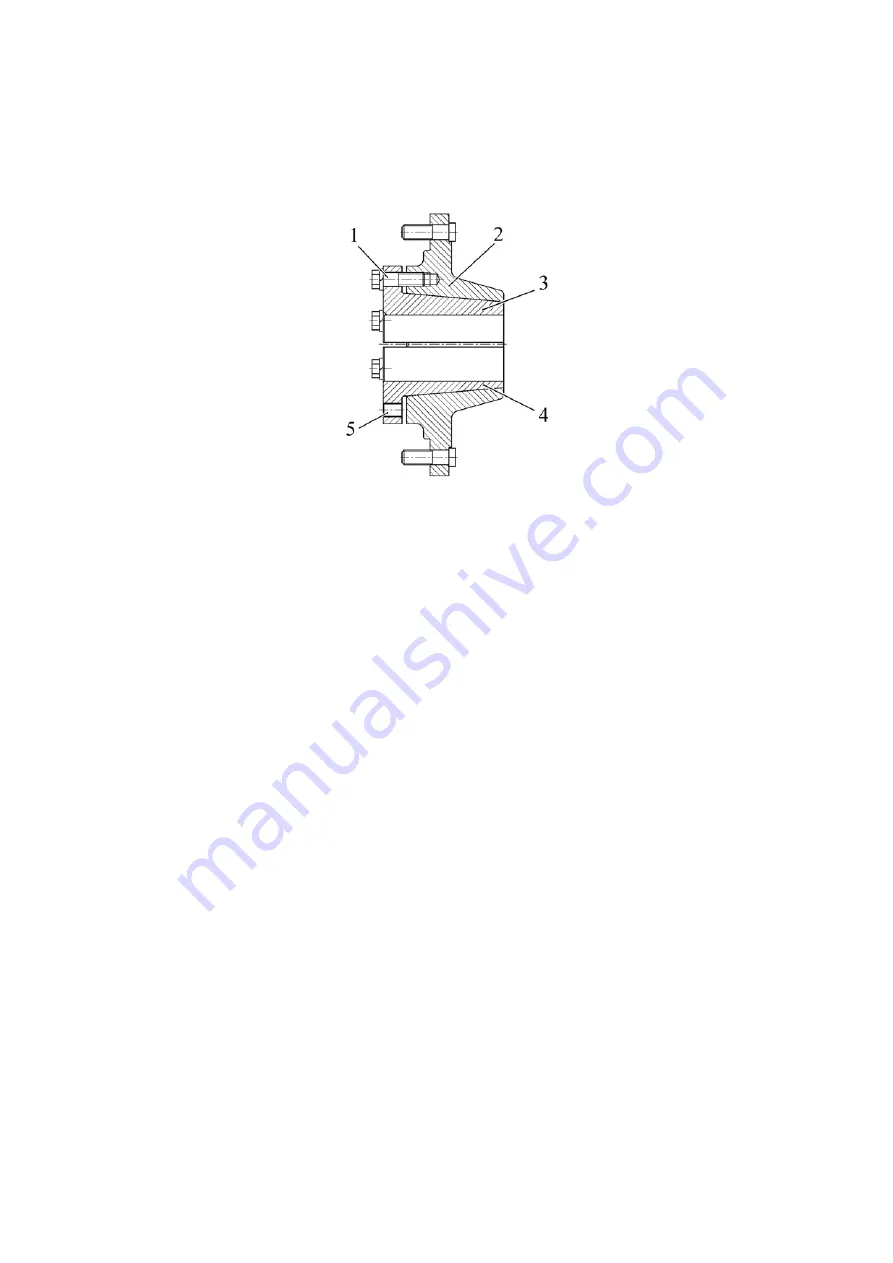

3.2.9 Rear wheel track formation

Tractor rear wheels are mounted on hub groups which consist of split conic bushings 3

and 4 (figure 3.2.4) and hub group housing 2.

The bushings are tightened into the hub group housing with six bolts 1 (M20) with a torque

from 360 to 450 Nm, clenching the semiaxle.

1 – tie bolts; 2 – hub group housing; 3 – upper bushing; 4 – lower bushing; 5 – dismount-

ing holes.

Figure 3.2.4 – Rear wheel hub group

The rear wheel track with the wheels of basic configuration 520/70R38 is changed by mov-

ing the hub and the wheel along the semiaxle and by replacing the wheels from one side-

board to the other one.

To change the rear wheel track, do the following:

- put the tractor on a flat ground, put the stops under the front and rear wheels, clean the

semiaxles from dirt;

- jack up the corresponding semiaxle tube;

- turn off the wheel retaining nuts and remove the wheel;

- release two tie bolts 1 (figure 3.2.4) of bushings 3 and 4 (one at each bushing) for three

complete turns. Screw out the rest of the tie bolts. Remove the blind plugs from the dis-

mounting holes. Screw in the bolts which were screwed out from the bushings into the

dismounting threaded holes;

- in case it is impossible to squeeze out the bushings with the help of tie bolts 1, fill

kerosine or other penetrant into the split between the bushings and the hub group housing,

wait for some time and then screw in the dismounting bolts, tapping on the hub group

housing at the same time until the bushings are completely squeezed out;

- shift the hub group onto the required track (use table 3.2.4 to set track “K” (figure 3.2.5)

by measuring dimension «L» from the semiaxle butt end to the bushing butt end);

- screw out the tie bolts from the dismounting holes and screw them into the bushings.

Screw in the tie bolts with a torque from 360 to 450Nm in stages – until all the bolts are

screwed in with the required torque;

- mount the wheel onto the hub group, tighten the wheel retaining nuts with a torque from

300 to 350Nm, set the blind plugs to their places;

- set the other wheel track in the same way;

- check and tighten the tie bolts and wheel retaining nuts after the first operation hour, after

the first eight – ten operation hours and every succeeding 125 operation hours.