2122.6-0000010 OM

205

Table 6.1.1 continued

Failure,

external manifestation, cause

Troubleshooting

Clutch lever 35 (figures 5.4.21 and 5.4.22) fails to go back to its initial position

when the clutch pedal is released

There is no clearance between the

main cylinder piston and piston follower

Adjust the clearance between main cylinder

piston and piston follower according to clause

5.4.2.12 “Operation 31. Check / adjustment of

clutch control”

There is no clearance between operat-

ing cylinder rod 25 (figure 5.4.21 and

5.4.22) and hydraulic booster 28 push

rod 27.

Adjust the clearance according to clause

5.4.2.12 “Operation 31. Check / adjustment of

clutch control”

Sticking (fails to go back to its initial position) of

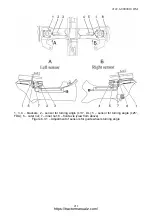

the main cylinder 11 piston 10 (figure 5.4.21) due

to piston cup and O-ring expansion, resulting in

closure of compensating port “

А

” (figure 6.1.1) in

cylinder manufactured by OJSC “Gidroprivod”.

Sticking (fails to go back to its initial position) of

the main cylinder 11 piston 10 (figure 5.4.22) due

to piston cup and O-ring expansion, resulting in

closure of compensating port “

А

” (figure 6.1.2) in

cylinder manufactured by “FENOX”.

Blocking of the main cylinder piston

due to piston cup expansion

Use of incorrect hydraulic-brake fluid or in-

gress of mineral oil, petroleum, kerosene, die-

sel fuel into hydraulic-brake fluid. Rinse the

hydraulic drive system with hydraulic-brake

fluid. Replace damaged cups and O-ring in the

main and operating cylinders. Replace hydrau-

lic-brake fluid. Bleed the hydraulic system with

hydraulic-brake fluid

Hydraulic cylinder piston strokes are

carried out with difficulty

Replace the hydraulic push rod

Clogging of compensating port “A” (fig-

ure 6.1.1 or 6.1.2) in the main cylinder

Unclog the compensating port of main cylinder

and bleed the hydraulic system of clutch control

Loss of pullback spring power 32 (fig-

ures 5.4.21 and 5.4.22).

Replace the pullback spring

Full clutch lever 35 stroke can not be achieved (figures 5.4.21 and 5.4.22) when the

clutch pedal is depressed

The clearance between the main cylin-

der piston and piston follower is not

properly adjusted

Adjust the clearance according to clause

5.4.2.12 “Operation 31. Check / adjustment of

clutch control”

The clearance between operating cyl-

inder 25 rod 26 (figures 5.4.21 and

5.4.22) and hydraulic booster 28 push

rod 27 is not properly adjusted

Adjust the clearance according to clause

5.4.2.12 “Operation 31. Check / adjustment of

clutch control”

Air presence in the clutch control hy-

draulic system

Bleed the hydraulic system with hydraulic-

brake fluid

Insufficient level of hydraulic-brake fluid

in the hydraulic system reservoir

Fill hydraulic-brake fluid to the required level in

the main cylinder reservoir. Bleed the clutch

control hydraulic system

Leakage of work space of the main and

operating cylinder due to damage, wear

of cups or O-rings

Replace cups or O-rings in the main and op-

erating cylinder in case they are worn out.

Check, if the cylinder bearing surface has

sharpened edges, ridges, or pits. Bleed the

clutch control hydraulic system

https://tractormanualz.com/