3522.5-0000010

РЭ

197

3.23.4.2 Installation of rear PTO RPM sensor

For installation of rear PTO RPM sensor the following shall be done:

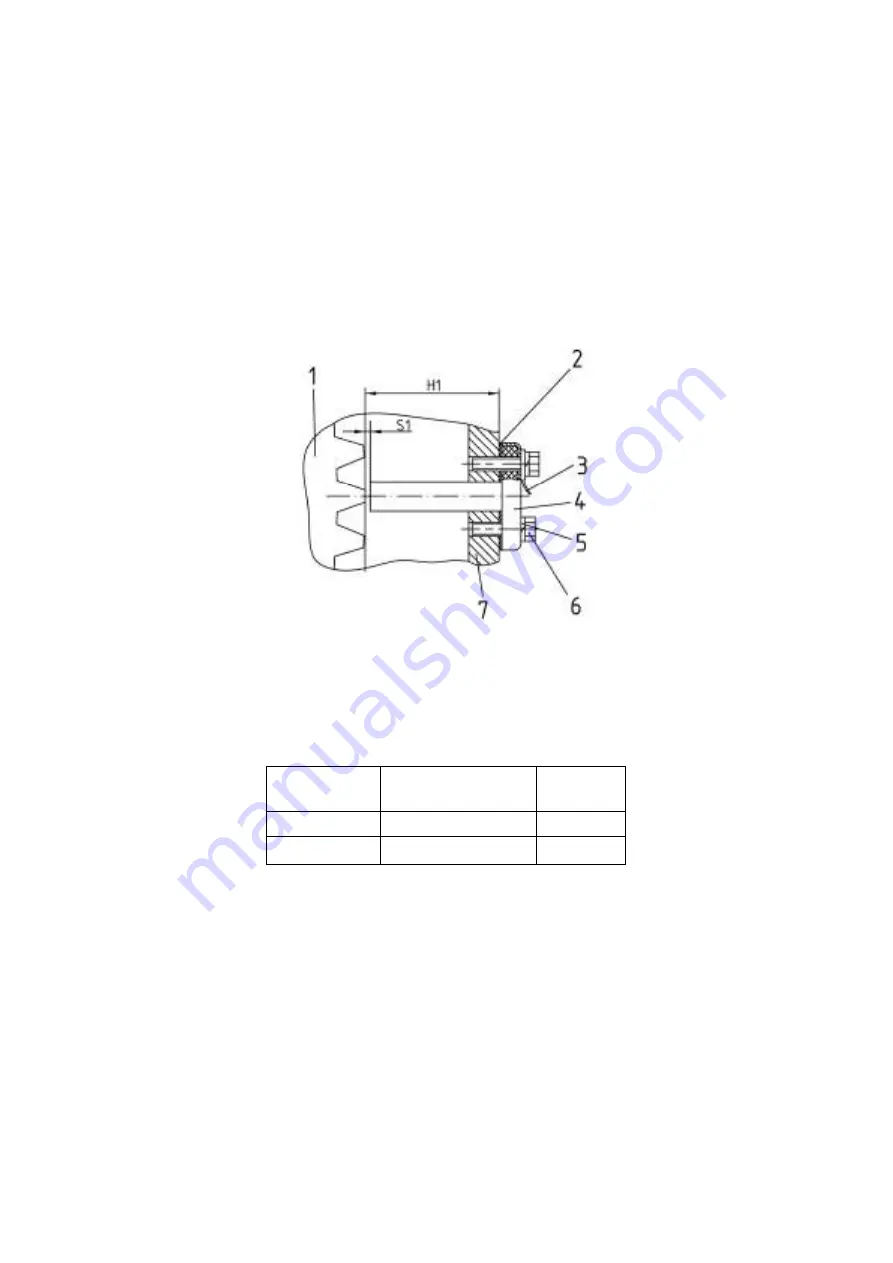

- put follower gear of PTO1 reduction unit (figure 3.23.5) with a tooth against the

hole in rear axle housing 7;

- it is necessary to measure length H1 and to put necessary quantity of shim wash-

ers 2 according to the table 3.7 to ensure free play S1;

- put “mass” wire 3 of the sensor 4 under any of screws 6;

- seal the screws 6 with sealing paste and tighten with moment 10…15 Nm.

1 – follower gear of PTO reduction unit; 2 – shim washer in thickness of 1mm; 3 –

¨mass¨ wire; 4 – PTO RPM sensor; 5 – washer; 6 – screw

М

8; 7 – rear axle housing.

Figure 3.23.5 – Installation of rear PTO RPM sensor

Table 3.7 – Installation of rear PTO RPM sensor

Н

1, mm

Q-ty of washers 2

(figure 3.23.5)

S1,

мм

67,0 – 67,8

2

2 – 2,8

67,9 – 68,36

1

1,9 – 2,36

https://tractormanualz.com/

Summary of Contents for 3522.5

Page 1: ...BELARUS 3522 5 3522 5 0000010 OM OPERATOR S MANUAL 2011 https tractormanualz com ...

Page 9: ...3522 5 0000010 РЭ 10 https tractormanualz com ...

Page 335: ...3522 5 0000010 OM 336 Service bulletins https tractormanualz com ...

Page 337: ...3522 5 0000010 OM 375 Annex B compulsory https tractormanualz com ...

Page 338: ...3522 5 0000010 OM 376 Annex B obligatory https tractormanualz com ...

Page 339: ...3522 5 0000010 OM 377 Annex C obligatory https tractormanualz com ...

Page 340: ...3522 5 0000010 РЭ Annex D obligatory 378 https tractormanualz com ...