Description

Bell & Gossett Series CRS Coalescing Removal Separators are designed to eliminate entrained air and separate debris

associated with start-up and maintenance of any hydronic system. The design incorporates an optional removable end

cover for coalescing medium access, and an optional air vent to automatically release air from the separator.

The design and construction conforms to ASME Section VIII, Div.1. This product is intended for hot and chilled water

systems.

Installation

A. PRE-INSTALLATION

1. Visually inspect Series CRS separator and check

for damage prior to installation.

Separator

Temperature

Max Working Pressure

CRS

-20°F (-29°C) to 450°F (232°C)

125 PSI (862 kPa)

Operational Limits

WARNING: Explosion or Rupture Hazard. A relief valve must be installed to prevent pressure in excess of local

code requirement or maximum working pressure designated in the Product Manual, whichever is less. Do not

expose Series CRS Coalescing Removal Separator to freezing temperatures or temperatures in excess of 450°F.

Failure to properly size the Product or follow these instructions may result in excessive strain on the system

and may lead to Product failure, serious or fatal personal injury, leakage, and/or property damage.

WARNING: Read carefully the product installation, operating and maintenance instructions. Failure to follow

the instructions and warnings in the manual may result in serious or fatal injury and/or property damage, and

will void the product warranty. This product must be installed by a qualified professional. Follow all applicable

local and state codes and regulations, in the absence of such codes, follow the current editions of the National

Plumbing Code and National Electric Code, as applicable.

WARNING: : This product, like most products under pressure, may over time corrode, weaken and burst or

explode, causing serious or fatal personal injury, leaking or flooding and/or property damage. To minimize risk,

a licensed professional must install and periodically inspect and service the Product. A drip pan connected to

an adequate drain must be installed if leaking or flooding could cause property damage. Do not locate in an

area where leaking could cause property damage.

WARNING: If the separator is damaged,

it must be replaced. Failure to follow this

instruction may result in serious personal

injury or death and property

damage.

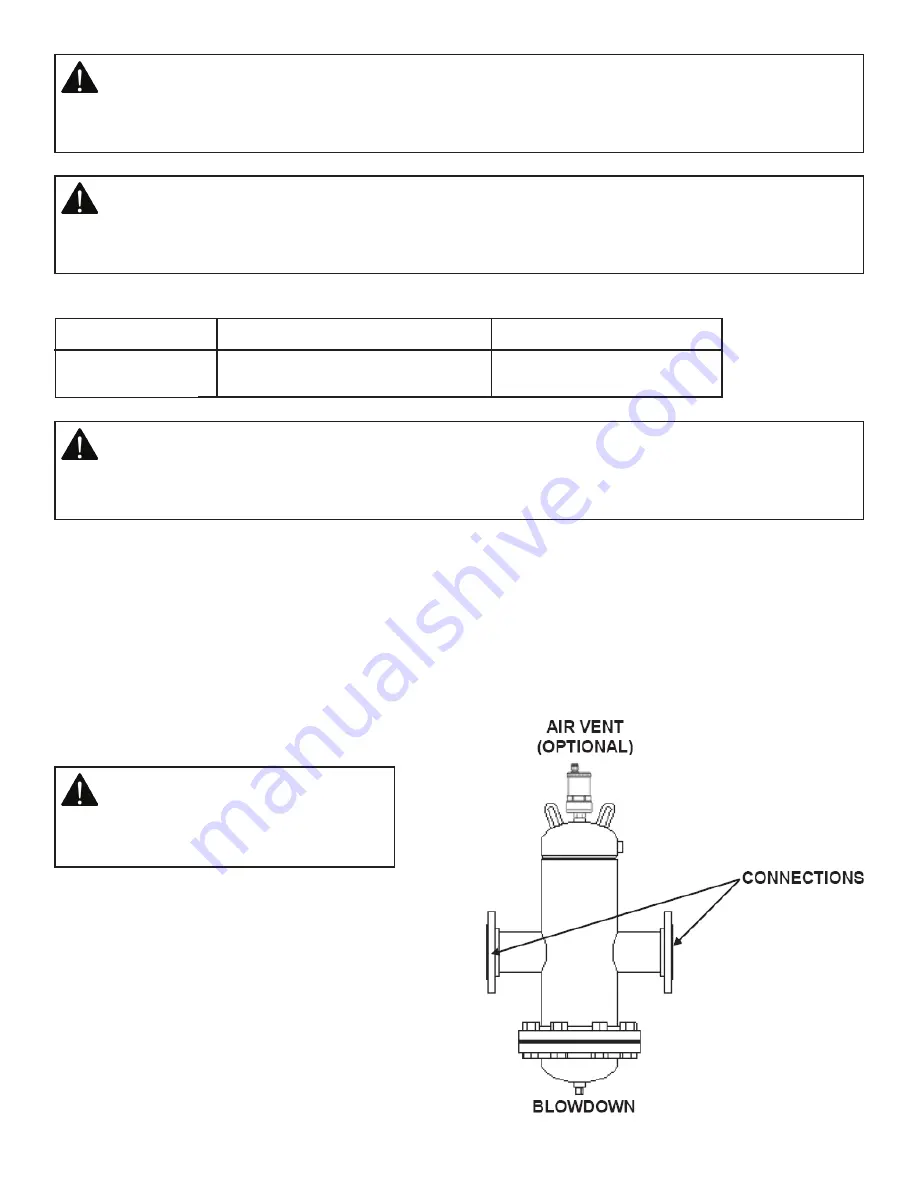

2. In order to protect the Series CRS separator

from shipping damage, some components are

shipped unattached and in a protective box. These

components are to be added to the Series CRS

separator on site. See Figure 1.

fig. 1