Wireless module

The wireless module is an optional module, to be coupled with the

ecocircXL circulators. When correctly configured, it generates a wire-

less network accessible by a mobile device, tablet or a personal com-

puter. See wireless module instructions manual for details.

5.2.11 Communication bus

The pump has a built-in RS-485 communication channel (terminals

15-16-17). See Figure 4 on page 8.

The pump can communicate with external BMS systems via Modbus or

BACnet protocol. For a complete description of the protocols, refer to

the advanced functions manual at www.bellgossett.com.

NOTICE:

When remote control is active, the set points and control modes are

managed only through communication channels and cannot be

changed via the user interface. The displayed quantity and unit of

measurement remain active on the user interface.

5.2.12 Automatic two-pump operation

Backup operation

Only the lead pump runs. The second pump starts in case of failure of

the lead pump.

Alternate operation

Only one pump runs at the time. The working time is switched every 24

hours so that workload is balanced between both pumps. The second

pump is started immediately in case of failure of the lead pump.

Parallel operation

Both pumps run simultaneously at the same set point. The lead pump

determines the behavior of the full system and is able to optimize the

performance. To guarantee the required performance with the mini-

mum power consumption, the lead pump starts or stops the lag (sec-

ond) pump to satisfy system requirement of flow and head.

6 System Setup and Operation

Precaution

CAUTION:

Always wear protective gloves when handling the pumps and

motor. When pumping hot liquids, the pump and its parts

may exceed 40°C (104°F).

NOTICE:

The pump must not run dry as this can result in the destruction of the

bearings. Fill the system correctly with liquid and vent the air before

first start-up.

NOTICE:

• Never operate the pump with discharge valve closed for longer

than a few seconds.

• Do not expose an idle pump to freezing conditions. Drain all liq-

uid that is inside the pump. Failure to do so can cause liquid to

freeze and damage the pump.

• The suction plus shut-off discharge pressure must not exceed the

pump pressure rating.

• Do not use the pump if cavitation occurs. Cavitation can damage

the internal components.

6.1 Configure the pump settings

Change the pump settings using one of the following methods:

• User interface

• Bus communication

• Wireless communication

6.1.1 Change the communication parameters

Change pump communication parameters. See

User interface

(page 8).

1.

Switch off the pump.

Wait until the power indicator light turns off.

2.

Switch on the pump.

3.

When the display shows COMM (COM), press the parameter but-

ton (3) to access the communication menu.

4.

Select one of the below parameters using the settings button (5).

• BAUD (BDR) = baud rate setup (available values 4.8 - 9.6 -

14.4 - 19.2 - 38.4 - 56.0 - 57.6 kbps)

• ADDR (ADD) = address setup (available address 1-255 for

Modbus 0÷127 for BACnet)

• MODU (MDL) = optional module setup (0 = no module; 1 =

Wireless module; 2 = RS-485 module)

5.

Press the parameter button to enter the submenu

6.

Edit the values using setting buttons.

7.

Press the parameter button to confirm and store the new values.

8.

Press mode button to exit the submenu.

9.

Repeat above procedure for each of the three parameters.

If no buttons are pressed for 10 seconds, then the pump exits the cur-

rent menu and continues start-up procedure. All the parameters that

are changed but not confirmed restore back to previous state.

6.1.2 Change the control mode

The pump can be controlled by a BMS (Building management system)

or other devices through the RS-485 communication port via Modbus

or BACnet protocol.

The following instructions are used when making the change on the

user interface. See

User interface

(page 8).

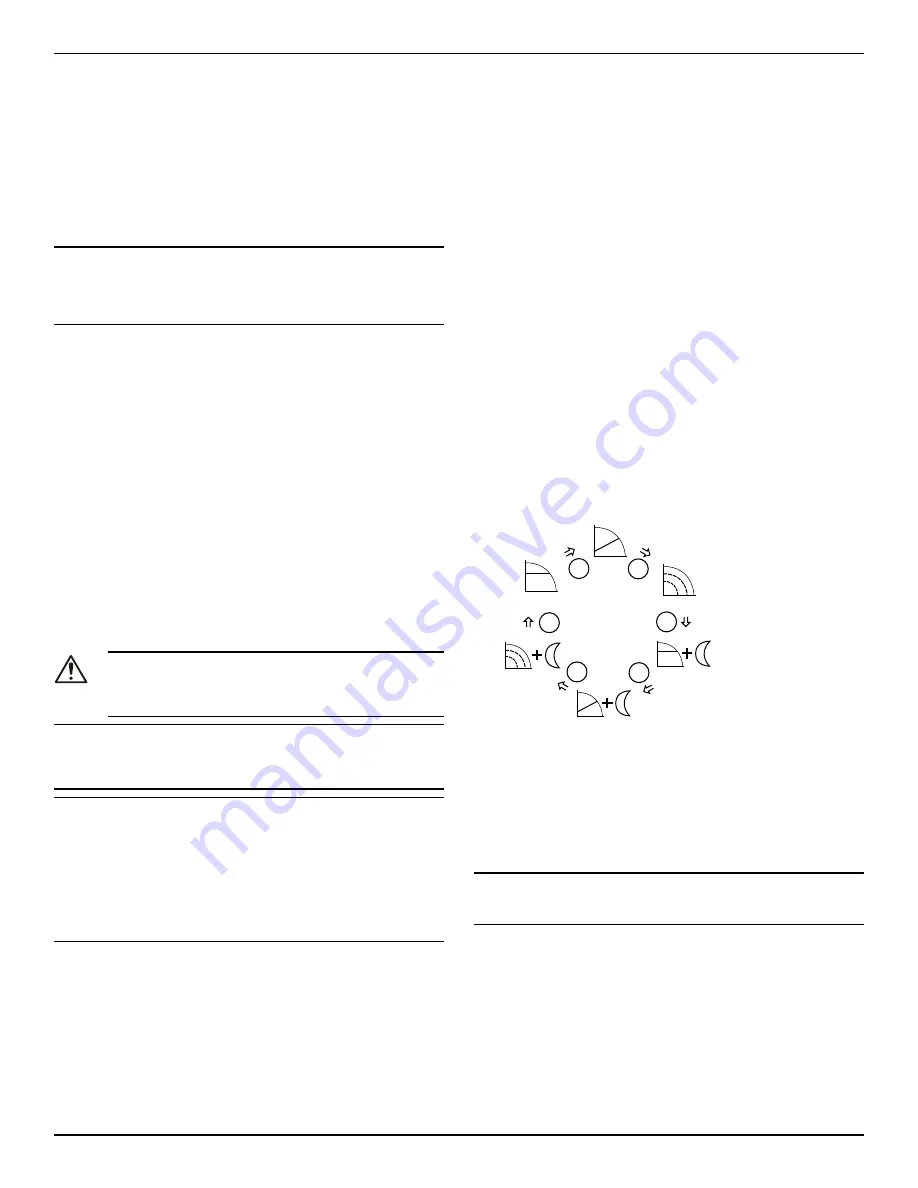

• Press the operating mode button (1).

• The operating modes are cyclically changed by the pressed but-

ton.

mode

mode

mode

mode

mode

mode

6.1.3 Change the set point

See

User interface

(page 8).

1.

Press one of the arrow setting buttons (5).

The display starts to blink.

2.

Change the value using the buttons (5).

3.

Wait 3 seconds to store and activate the new set point.

The display will stop blinking to confirm the change.

NOTICE:

If a check valve is installed on the system, ensure that the pump head is

sufficient to allow flow through the system.

6.1.4 Change the displayed unit of measurement

Power, Flow, Head and Speed parameters cyclically change by press-

ing the parameter button (3). In order to change the unit of measure-

ment, follow these steps:

1.

Press the button (3) to change the unit of measurement. See

User

interface

(page 8).

6 System Setup and Operation

10

ecocirc XL Installation, Operation, and Maintenance manual