• Bodily injuries

• Material damages

• Economic losses

Warranty claim

Xylem products are high-quality products with expected reliable oper-

ation and long life. However, should the need for a warranty claim

arise, contact your local sales and service representative.

1.5 Spare parts

WARNING:

Only use original spare parts to replace any worn or faulty

components. The use of imitation spare parts may cause mal-

functions, damage, and injuries as well as void the warranty

and the UL listing.

2 Transportation and Storage

2.1 Inspect the delivery

1.

Inspect the package for damage or missing items upon delivery.

2.

If applicable, unfasten the product by removing any screws, bolts,

or straps. For your personal safety, be careful when you handle

nails and straps.

3.

Remove packing material from the product.

4.

Dispose of all packing material in accordance with local regula-

tions.

5.

Inspect the product to determine if any parts have been damaged

or are missing.

Contact your local sales representative if there are any issues.

2.2 Transportation guidelines

Precautions

WARNING:

• Observe accident prevention regulations in force.

• Crush hazard. The unit and the components can be

heavy. Use proper lifting methods and wear steel-toed

shoes at all times.

Check the gross weight that is indicated on the package in order to se-

lect proper lifting equipment.

Position and fastening

The unit should be transported in an upright position as indicated on

the package. Make sure that the unit is securely fastened during trans-

portation and cannot roll or fall over. The product can be safely trans-

ported at ambient temperature from -40°F to +158°F (-40°C to +70°C)

with humidity <95% (non-condensing) and protected against dirt, heat

source, and mechanical damage.

2.3 Storage guidelines

2.3.1 Storage location

NOTICE:

• Protect the product against humidity, dirt, heat sources, and me-

chanical damage.

• The product must be stored at an ambient temperature from

-13°F to +131°F (-25°C to +55°C) and humidity < 95% (non-con-

densing).

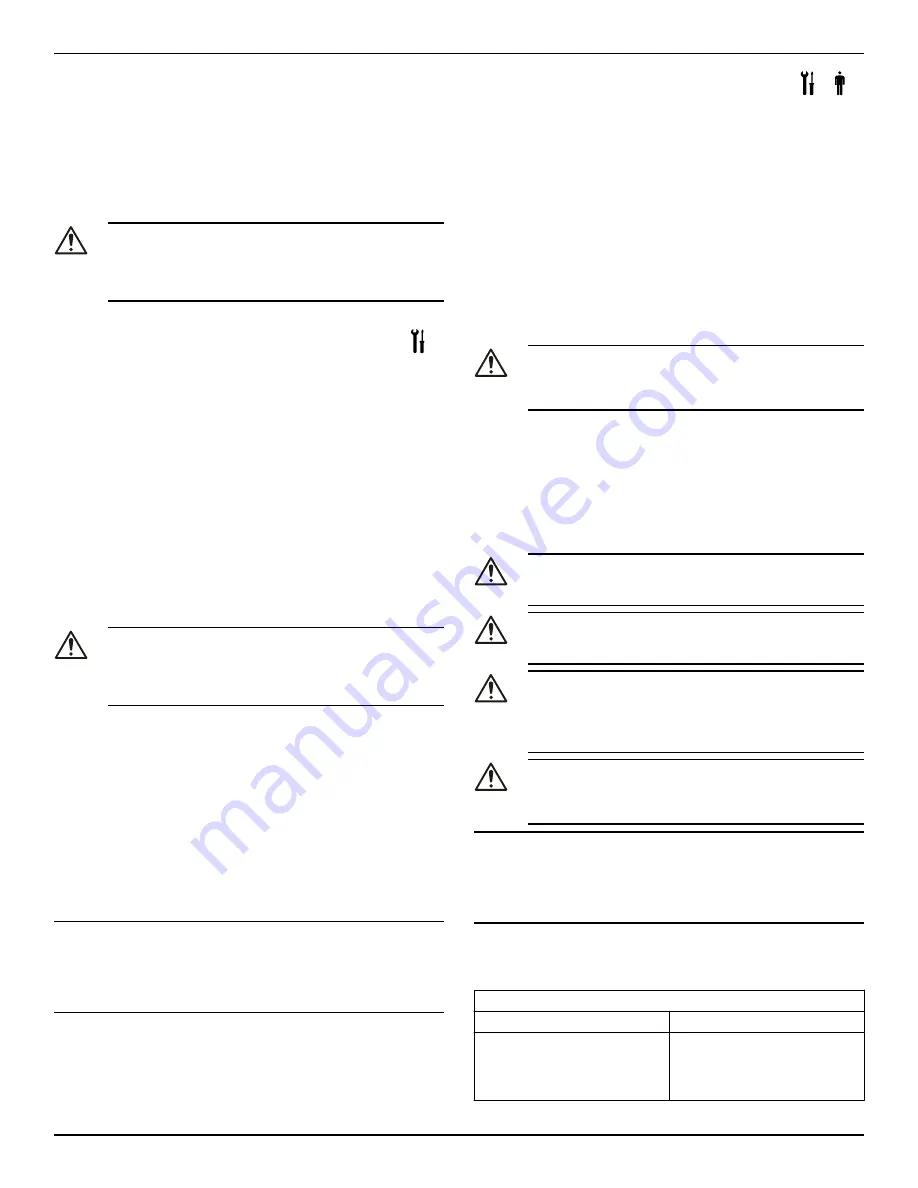

3 Product Description

3.1 Pump design

• The ecocirc XL is a large wet rotor pump with energy efficient,

electronically commutated permanent magnet motor.

• The pump is designed for systems with variable flow rates to opti-

mize pump operation thus reducing energy consumption. The

pump can be set to any one of the multiple operating modes

available, with each designed for a specific application to achieve

high performance and maximum energy savings.

• A single pump can handle heating, cooling, and plumbing appli-

cations with a choice for cast iron or bronze lead-free body pumps

to handle HVAC and potable water applications. The pumps are

also suitable for a 50/50 percent water/glycol circulating fluid. The

built-in electrical overload and dry run protection provide safety

and protection to pump from damage.

Intended use

WARNING:

California Proposition 65 warning! This product contains

chemicals known to the state of California to cause cancer

and birth defects or other reproductive harm.

The pump is suitable for:

• Potable hot water (only with bronze pump body models)

• Hot water heating systems

• Cooling and cold water systems

The pump can also be used for:

• Solar systems

• Geothermal applications

Improper use

DANGER:

Do not use this pump to handle flammable and/or explosive

liquids.

WARNING:

Unintended use of the pump may create dangerous condi-

tions and cause personal injury and damage to property.

WARNING:

Do NOT install this pump in swimming pools or marine areas.

Failure to follow these instructions could result in serious per-

sonal injury, death and/or property damage.

THIS IS A NON-SUBMERSIBLE PUMP

WARNING:

Do NOT exceed the maximum working pressure of the

pump. This information is listed on the nameplate of the

pump.

NOTICE:

Do not use this pump to handle liquids containing abrasive, solid, or

fibrous substances, toxic or corrosive liquids, potable liquids other than

water, or liquids not compatible with the pump construction material.

Water pH must be maintained between 7-9 and water hardness must

not exceed 14 grains/ gallon.

An improper use of the product leads to the loss of the warranty.

3.2 Product nomenclature

Example: ecocirc XL B 15–75

ecocirc XL

high efficiency pump series

B

Pump type:

Blank = Cast iron

B = bronze pump body for pota-

ble hot water pumping

2 Transportation and Storage

4

ecocirc XL Installation, Operation, and Maintenance manual