Example: ecocirc XL B 15–75

-15

Maximum pump head (FT)

-75

Maximum pump flow rate (GPM)

3.3 Technical data

Feature

Description

Motor model

Electronically commutated motor with perma-

nent magnet rotor

Series

ecocirc XL

Rated voltage

1 x 115 V ±10%

1 x 208–230 V ±10%

Frequency

50/60 Hz

Power consumption

100–1700 W

IP protection

IP 44

Insulation class

Class 155 (F)

Maximum working

pressure

The maximum pressure is indicated on pump

nameplate

175 PSI (12 bars)

Liquid temperature

range

14°F (-10°C) to 230°F (110°C)

Ambient temperature

range

32°F (0°C) to 104°F (40°C)

Ambient humidity

95% non-condensing

Pumping media

Water and water/glycol mixtures

1

up to 50%.

Sound pressure

≤ 43 dB (A)

EMC (electromagnetic

compatibility)

EN 55014-1:2006 + A1:2009 + A2:2011, EN

55014-2:1997 + A1:2001 + A2:2008, EN

61000-3-2:2006 + A1:2009 + A2:2009, EN

61000-3-3:2008, 61800-3:2004+A1:2012.

Leakage current

< 3.5 mA

I/O aux15 VDC

power supply

Imax < 40 mA

Fault signal relay

Vmax < 250 VAC

Imax < 2 A

CSA certification

NSF/ANSI-372 compliant (bronze body parts)

3.4 Scope of delivery

Inside the package you will find:

• Pump unit

• Insulating shells for pump body — for heating applications

• O-ring to be used as replacement between motor housing and

pump body

• Two (2) gaskets for flanged connection

• 20 mm x ½” NPT electrical fitting

• IOM and Quick Start guide

3.5 Accessories

• Companion flanges

• Fastener Packs consisting of 4 bolts and 4 nuts (for 2–bolt models)

• Fastener Packs consisting of 8 bolts and 8 nuts (for 4–bolt models)

• Pressure sensor (for details see section 5.2.10 of this manual)

• Temperature sensor (for details see section 5.2.10 of this manual)

• Wireless module

• RS–485 module

4 Installation

Precautions

WARNING:

• Observe accident prevention regulations in force.

• Use suitable equipment and protection.

• Always refer to the local and/or national regulations,

legislation, and codes in force regarding the selection of

the installation site, plumbing, and power connections.

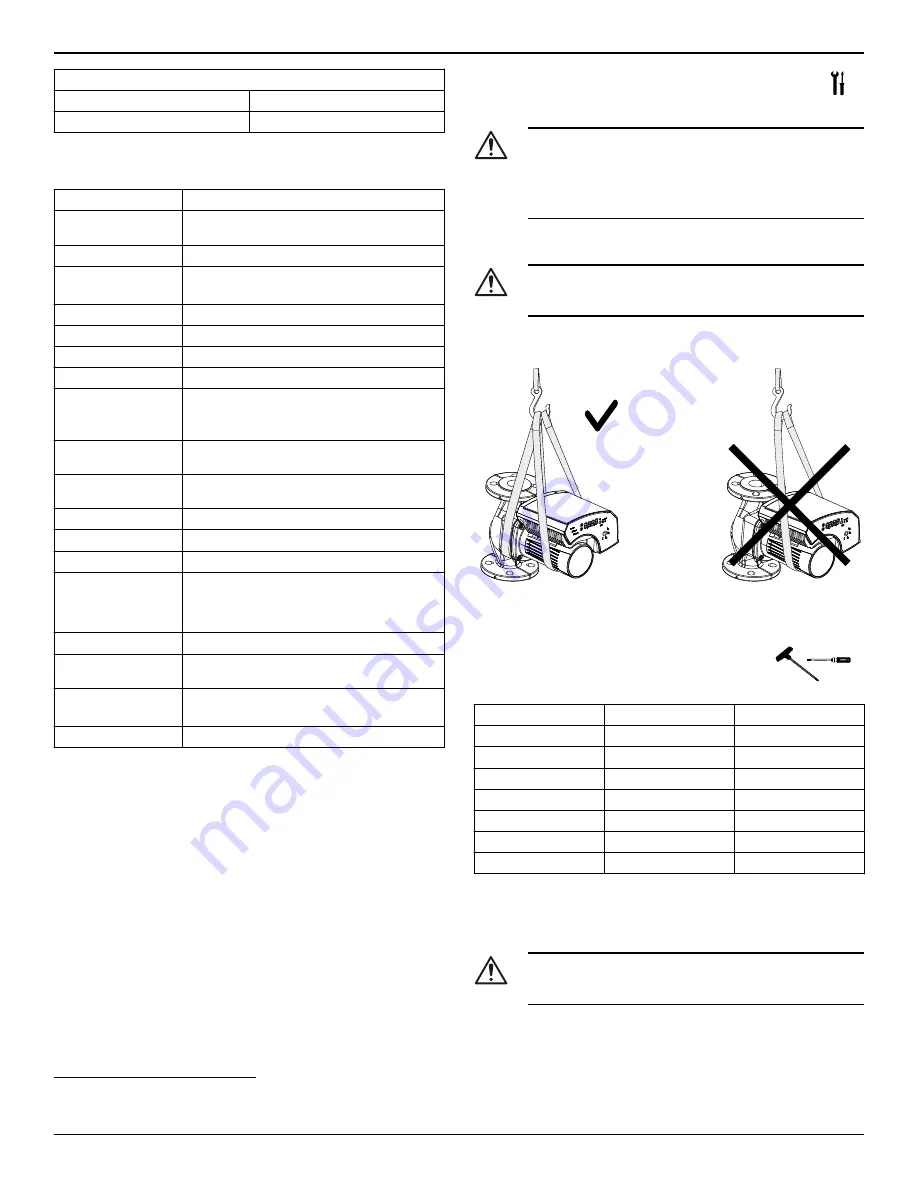

4.1 Pump handling

WARNING:

Observe local codes and regulations setting the limits for

manual lifting or handling.

Always lift the pump by the motor housing or pump body. If the pump

weight exceeds the manual handling limits, use lifting equipment with

lifting straps.

4.2 Tools required for pump installation

• T-Handle with allen screw

• Control screw driver – with 2 mm blade size

Model number

Allen screw size (mm) T-handle length (in)

20–35

5

8

36–45

5

8

15–75

5

8

55–45

6

10

20–140

6

10

65–130

8

12

40–200

8

12

4.3 Facility requirements

4.3.1 Pump location

DANGER:

Do not use this unit in environments that may contain flam-

mable/explosive or chemically aggressive gases or powders.

Guidelines

Observe the following guidelines regarding the location of the prod-

uct:

1

The pump can be used with water/propylene glycol mixtures up to 50% with a maximum viscosity of 50cST at 14°F (-10°C). The pump has built-in overload and

thermal protection to protect the pump from overload due to increased fluid viscosity. Pump performance is based on 77°F (25°C). Therefore pumping of glycol

mixtures will affect max performance, depending on mixture concentration and temperature.

4 Installation

ecocirc XL Installation, Operation, and Maintenance manual

5