17

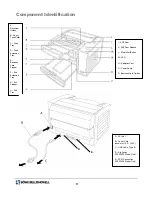

I – ADF Door

J – ADF Door Release

L – Stop / Start Button

M – LED

N – Radiation Vent

O – Power Switch

P – Business Card Guides

A -

Document

Guides

B - Paper

Feed Roller

C – Feed

Tray

D – Feed

Extension

Tray

E –

Business

Card

Stopper

F – Exit

Extension

Tray

G – Exit

Stopper

H – Exit

Tray

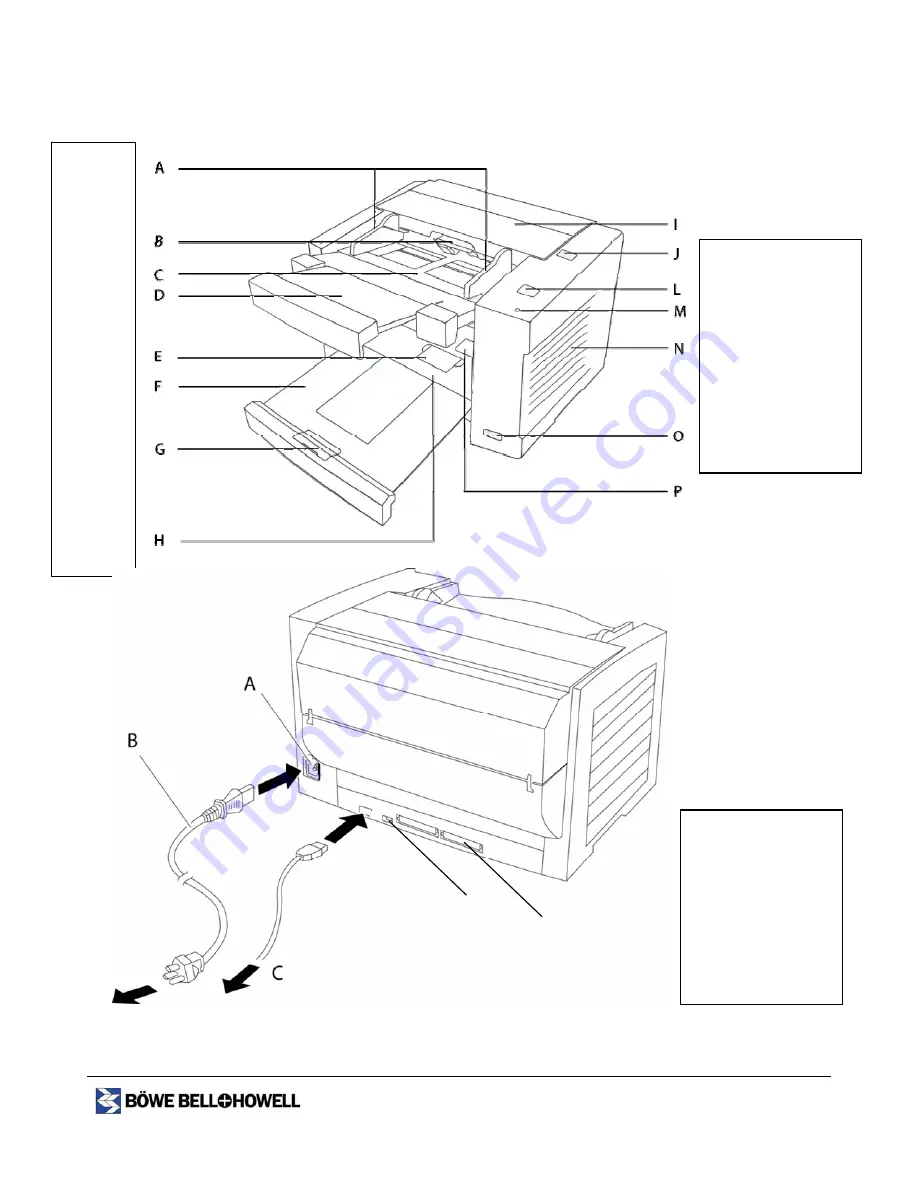

A – AC Inlet

B – Power Cord

(shown for 100 – 120V)

C – USB Cable Type B

D – Dip Switch

(1200/1400 Model Only)

E – SCSI Connection

(1200/1400 Model Only)

D

E

Component Identification