10

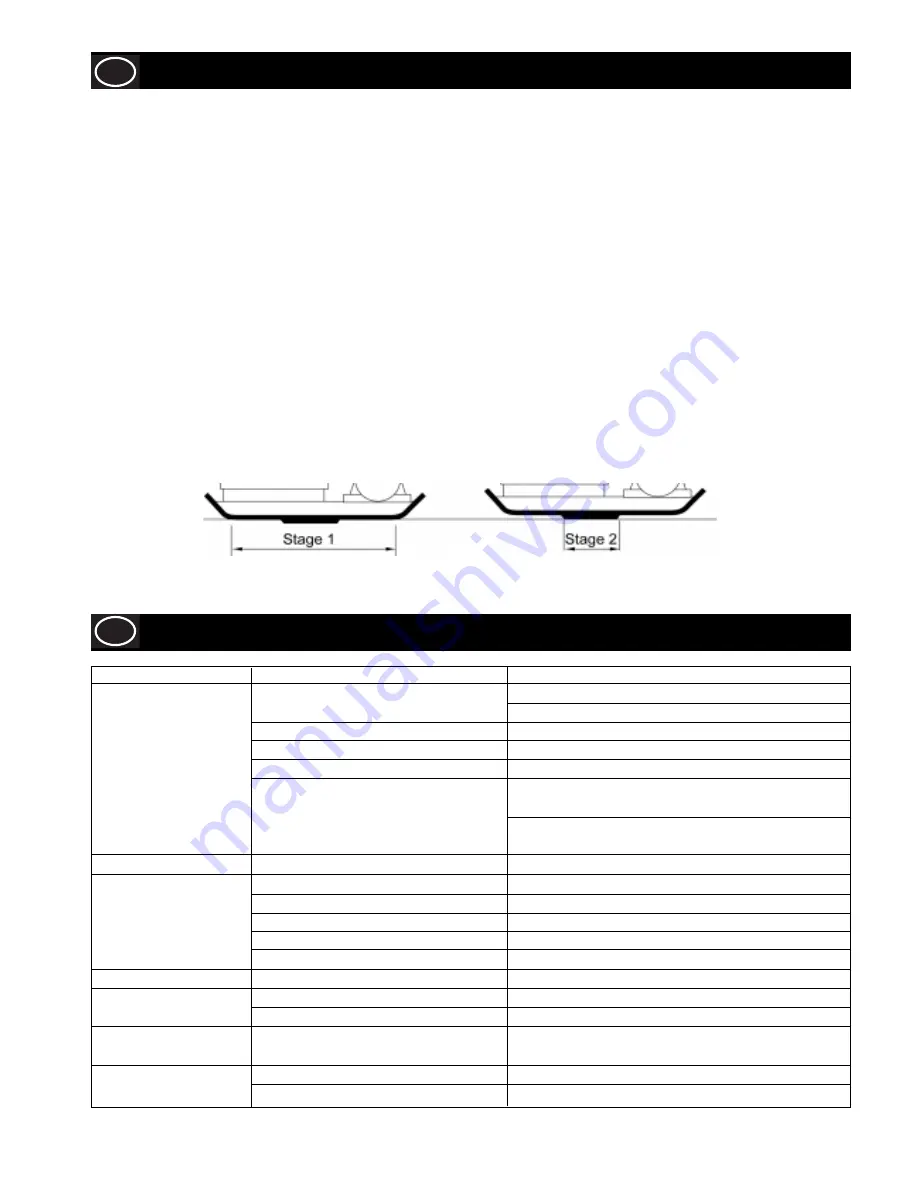

Stage 1:

The full base area compacts the material like a standard machine.

Stage 2:

The base rises onto the ‘Dual Force’ section to give 3 to 4 times the compaction force of standard plates.

Compaction Speci

fi

cation

Various methods have been employed in the past to specify the compaction required for various applications. The factors to consider

are, material properties, layer thickness, pressure applied, vibration and number of passess. Greater

understanding of how compaction works has lead to new compaction speci

fi

cations being introduced.

The most up to date speci

fi

cation is part of the U.K.’s NRSWA (New Roads & Street Works Act). Civil Engineers are now adopting

these speci

fi

cations to ensure good compaction for all site work.

NRSWA (HAUC speci

fi

cation).

The speci

fi

cation was compiled by HAUC (Highways Authorities & Utilities Committee).

The ‘New Roads and Street Works Act 1991, set a new standard for road repairs and reinstatements in the UK. It covers materials,

methods, equipment and safety when carrying out reinstatements on roads and footways.

The reason for the act is to ensure repairs and reinstatements are carried out to a higher standard and ultimately last longer. This in

turn will reduce the need for costly remedial work and reduce traf

fi

c delays.

There are two categories speci

fi

ed for plate compactors.

1. 1400 to 1800kg/m²

2. Over 1800kg/m²

These

fi

gures relate to the static pressure applied by the machine

NOTE:

No standard single direction plate compactors comply with this minimum speci

fi

cation. For highways work always use a ‘Dual

Force’ plate compactor.

DUAL FORCE

Belle Group studied the act then developed and patented equipment to enable contractors to comply with the act’s requirements.

The NRSWA legislation requires that compaction equipment meets the minimum speci

fi

cation. By purchasing an Belle Group ‘Dual

Force’ plate, you are immediately complying with this part of the act. To comply with the speci

fi

cation and maintain surface tolerance,

Belle Group ‘Dual Force’ base plates are divided into two areas providing two stages of compaction.

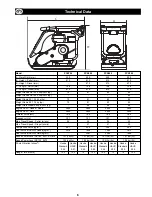

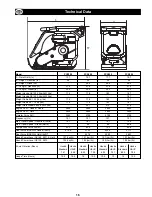

GB

Troubleshooting Guide

GB

Problem

Cause

Remedy

Engine will not start.

No fuel.

Open fuel tap.

Fill

fuel

tank.

Engine switched off.

Switch engine on.

Spark plug fouled.

Clean and reset plug gap.

Engine

cold.

Close

choke.

Engine

fl

ooded.

Honda, open choke, fully open throttle, pull recoil starter

until

engine

fi

res.

Hatz, move speed control to stop, pull recoil starter 5

times then repeat start procedure.

Engine still will not start.

Major Fault

Contact Agent or Belle Group.

Unit will not vibrate.

Engine speed too slow.

Set engine speed control to fast.

Drive belt tension loose.

Adjust belt tension.

Air

fi

lter blocked.

Clean or renew air

fi

lter.

Drive failure.

Contact Agent or Belle Group.

Vibrator failure.

Contact Agent or Belle Group.

Asphalt adhering to plate. Lack of lubrication.

Use a water spray system.

Paving blocks damaged. Plate in direct contact with material.

Use a paving pad.

Standard pad used on Dual Force plate.

Fit correct Dual Force Pad

Bituminous surface

Over compaction.

Remove and relay.

fl

aking

(laminating).

Low travel speed

Layer thickness too deep.

Remove some of the material.

(plate sinking).

Moisture content too high or too low.

Remove material and adjust.