11

3.2.1 - ROUTINE MAINTENANCE SCHEDULE.

RUNNING HOURS

ITEM.

ATTENTION

10

100

300

Complete Unit

Keep all areas clean and free

from dust , debris, etc.

Check security of all

fasteners especially on

Engine Mountings.

*

*

Wheels & Feet.

Examine for damage.

*

Transmission hoses

Examine for leaks or

damage.

Check for correct positioning

of protective sleeve.

*

*

*

*

*

*

Engine.

Check oil level.

Examine engine mountings.

Examine Exhaust silencer for

damage or deterioration.

Check for excess vibration

when running.

Change Oil/Service.

Refer to manufacturers

instructions

Hydraulic Tank

Check oil level.

Replace Filter.

Change Hydraulic Oil

*

*

*

Oil Cooler.

Externally clean using

compressed air

DO NOT

USE WIRE BRUSH

.

*

Return line Filter.

Replace or when indicator

shows clogged.

*

Hydraulic pipes/ Connections

Examine for oil leaks

*

Summary of Contents for Major 30-140

Page 22: ...22 4 3 PARTS IDENTIFICATION LISTS Fig 3 1 FRAME CHASSIS ASSY ...

Page 24: ...24 Fig 3 2 Tank Assy ...

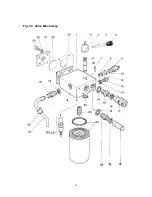

Page 26: ...26 Fig 3 3 Valve Block Assy ...

Page 28: ...28 Fig 3 4 Cooler Assy ...

Page 30: ...30 Fig 3 5 Pump Assy ...

Page 32: ...32 Fig 3 6 P O D Assy ...

Page 34: ...34 Fig 3 7 Hose Assy ...