Page 18

Page 19

BOILERMA

TE

2000

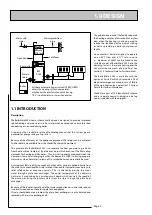

Electrical Supply requirements for BoilerMate

2000

with Switch

2.0 INSTALLATION

2.1 SITE REQUIREMENTS

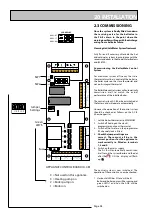

The appliance is designed to be installed in an airing/cylinder cupboard and the

relevant minimum dimensions are provided in section 1.2 Technical Data.

Because of the ease of installation we recommend that the cupboard construction

is completed and painted before installation of the appliance. The cupboard door

can be fitted after installation.

If the unit needs to be stored prior to installation it should be stored upright in a

dry environment and on a level base/floor.

Installation and maintenance access is needed to the front of the appliance and

above the F & E cistern. See Technical Data section for further details.

The minimum dimensions contained in section 1.2 Technical Data allow for the

passage/connection of pipes to the appliance from any direction as long as the

appliance is installed on the installation base provided. If the installation base is

not used extra space may be needed to allow connection to the pipework and the

whole of the base area should be continuously supported on a material which will

not easily deteriorate if exposed to moisture.

The floor of the cupboard needs to be level and even and capable of supporting

the weight of the appliance when full. Details of the weight when full is provided

in section 1.2 Technical Data.

The appliance is designed to operate as quietly as practicable. However, some noise

(from pumps etc) is inevitable in any heating system. This will be most noticeable

in cupboards formed on bulkheads, or at the mid span of a suspended floor. In these

cases the situation can be improved by placing the appliance on a suitable sound

deadening material (i.e. carpet underlay or similar).

Cupboard temperatures will normally be higher than in a conventional system

and the design of the cupboard and door will need to take this into account. No

ventilation is normally required to the cupboard.

A suitable location will be needed for the separate feed and expansion cistern.

This will often be at high level in the cupboard housing the BoilerMate 2000. The

dimensions and clearances are provided in section 1.2 Technical Data. The location

will need to provide a suitable route for the cold feed and expansion pipe as well

as the open safety vent pipe. The location will also need to provide a suitable

route and discharge position for the warning/overflow pipe and the ballvalve supply

from the mains cold water system.

l

a

n

i

m

o

N

d

a

o

l

ll

u

f

t

n

e

r

r

u

c

f

o

g

n

i

t

a

r

n

i

M

g

n

i

t

a

l

o

s

i

h

c

t

i

w

s

e

z

i

s

e

l

b

a

C

d

e

d

n

e

m

m

o

c

e

r

.

x

a

M

n

o

d

e

s

a

b

-

n

u

r

e

l

b

a

c

4

.

0

d

n

a

p

o

r

d

V

2

.

9

n

o

i

t

c

e

n

n

o

c

s

i

d

d

n

o

c

e

s

e

p

y

t

a

g

n

i

s

u

e

m

i

t

r

e

k

a

e

r

b

B

r

o

1

s

p

m

A

0

.

1

4

s

p

m

A

5

4

m

m

0

1

2

s

e

r

t

e

m

9

4

t

i

u

c

r

i

c

d

e

d

n

e

m

m

o

c

e

R

d

e

s

a

b

-

e

c

i

v

e

d

n

o

i

t

c

e

t

o

r

p

n

o

i

t

c

e

n

n

o

c

s

i

d

d

n

o

c

e

s

4

.

0

n

o

e

m

i

t

1

7

8

3

S

B

o

t

.

B

.

C

.

M

-

1

e

p

y

t

A

5

4

N

E

S

B

o

t

r

e

k

a

e

r

b

t

i

u

c

r

i

c

B

e

p

y

t

A

5

4

8

9

8

0

6

An electrical supply must be available which is

correctly earthed, polarized and in accordance

with the latest edition of the IEE requirements

for electrical Installations BS 7671.

The electrical mains supply needs to be

230V/50Hz.

Connection must be made using a double-pole

linked isolator with a contact separation of

3mm in both poles which is located within 1m

of the appliance. The supply must only serve

the appliance.

The supply to the standard appliance shall be

fused at 3 amp.

If the ‘Switch’ electrical emergency backup

is being provided, the minimum breaking

capacity of the main isolation switch and

cable sizes/lengths at 230V shall follow the

recommendations in the table below.

Summary of Contents for Gledhill BoilerMate 2000 125

Page 8: ...Page 8 1 0 DESIGN 1 2 TECHNICAL DATA...

Page 33: ...Page 33 BOILERMATE 2000 3 0 SERVICING...

Page 42: ......

Page 43: ......

Page 44: ......