Page 28

Page 29

BOILERMA

TE

2000

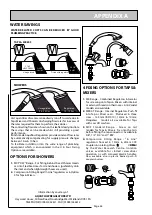

When commissioning the system

• If the boiler is range rated, then adjust it to the

maximum

heat input.

•

Check the boiler thermostat is set to maximum.

•

Set the boiler pump speed so that the temperature difference across the

boiler is

about 8°C

- when the space heating is off.

NOTE

: For optimum

performance when using a condensing boiler such as the Keston C25 set

the boiler pump in the BoilerMate to give about 15ºC temperature rise across

the boiler.

•

Set the heating system pump speed so that the temperature difference across

the flow and return

is not greater than 11°C.

• Check the DHW plate heat exchanger pump is set to maximum.

• Check that there is no overflow when the whole of the system is fully up

to temperature.

• Check that the Y type strainer on the incoming mains cold water inlet to the

appliance is clean.

Note

: If the appliance is operating at mains cold water pressures below 11⁄2 bar the

flow regulator fitted on the outlet to the Y type strainer can be removed if required

to improve performance.

Because the A.C.B is able to adjust to suit the

water temperatures delivered by the boiler the

thermostat should always be set at maximum

during commissioning.

However, the boiler thermostat setting can be

reduced in summer, in the normal way, if the

appliance is being used for hot water only.

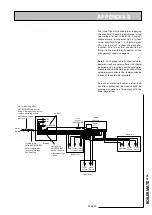

The temperature settings established during

commissioning can be checked using push

button switches sw1 and sw2 on the PCB as

described in section 3.3 Fault Finding.

The clock/programmer provided on the

appliance controls the heating system only

and should be set to suit the householders

requirements using the instructions shown

on the separate leaflet and the label on the

front of the appliance. If the appliance is fitted

with Switch (see figure on page 25) the boiler

should be switched off and Switch operated

to ensure it is working correctly.

• When the selector knob is not in normal

position, the PCB, room thermostat and

the time clock are electrically isolated.

• When the selector knob is in HW only

position the plate heat exchanger pump

will run continuously at full speed.

• When the selector knob is in the HW and

HTG position, the plate heat exchanger

pump and the heating pump will run

continuously.

This product is covered by the ‘Benchmark’

scheme and a separate commissioning/

service log book is included with this

product. This must be completed during

commissioning and left with the product

to meet the Warranty conditions offered

by Gledhill.

On completion:-

1. Do ensure that the electrical connection

(e.g. mains supply, room thermostat) to

the unit is correct and tight before

starting the commissioning procedure.

2. Do ensure that the functioning and

control of the system is explained to the

occupant.

These Instructions should be placed along with

the component manufacturers instructions in the

pocket provided on the rear of the front panel.

The front panel should then be refitted.

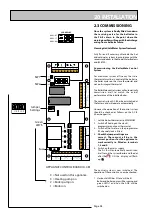

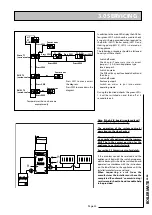

2.3 COMMISSIONING

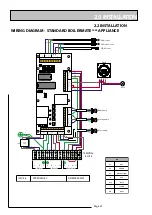

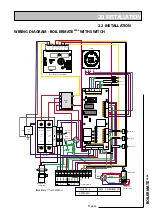

2.0 INSTALLATION

Note:

The controls within the A.C.B will not allow the heating system to function

until the store temperature has reached 60°C. Therefore although the LED bar 1

‘HT’ will light when heating is switched on, the heating pump (Green LED -3) will not

switch on if the store temperature is less than 60°C. Time will need to be allowed for

this to happen during initial commissioning. This will vary depending on the boiler

size and the model of the BoilerMate 2000 being used.

2. Once a temperature of 60°C has been reached on the thermal store, switch on

space heating clock/programmer and room thermostat.

•

Horizontal LED bar 1 ‘HT’ will light.

•

Green LED 3 on the A.C.B will switch on.

Heating pump will run.

3. Switch off space heating on clock/programmer or room thermostat

•

Horizontal LED bar 1 ‘HT’ will switch off.

•

Green LED 3 on the A.C.B will switch off.

Heating pump will switch off.

4. Open the hot tap

•

Horizontal LED bar 3 ‘HW’ on the LED display will light.

•

Domestic hot water pump will run.

5. Close the hot water tap

•

Horizontal LED bar 3 will switch off

•

Domestic hot water pump will continue to run for a short period of time before

switching off.

6. The A.C.B incorporates a 3 minute pump overrun facility. Check green LED

2 remains lit for this period of time when the boiler switches off i.e. the

thermal store reaches temperature.

The control functions have now been checked.

Let the boiler heat the store and when the store is satisfied, i.e. green LED’s 1 and 2

on the A.C.B are off, the radiator circuit and hot water can be checked and balanced

in the normal way.

The boiler thermostat should be left

at maximum

for optimum performance/

efficiency.

Summary of Contents for Gledhill BoilerMate 2000 125

Page 8: ...Page 8 1 0 DESIGN 1 2 TECHNICAL DATA...

Page 33: ...Page 33 BOILERMATE 2000 3 0 SERVICING...

Page 42: ......

Page 43: ......

Page 44: ......