Page 4

Page 5

BOILERMA

TE

2000

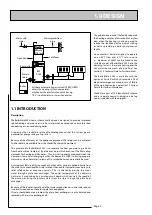

The BoilerMate 2000 shown schematically above is designed to provide improved

space heating and mains pressure hot water when coupled to any remotely sited

condensing or non condensing boiler.

A report by the Cranfield Institute of Technology found that this system gives a

potential for energy savings of up to 15%.

Because of the efficiency of the appliance improved SAP ratings can be achieved.

Further details are available from the Gledhill Technical Department.

The principle of a BoilerMate 2000 is to separate the heat generator e.g. a boiler

from heat emitters (radiators) by a thermal store, which evens out the fluctuating

demands for heating and hot water. Thus, by storing energy produced when the

demand is low and discharging it when the demand is high (i.e. during property

warm up or when hot water is drawn off), a smaller boiler can potentially be used.

An important feature of this concept is that hot water can be supplied directly from

the mains at conventional flow rates without the need for temperature and pressure

relief safety valves or expansion vessels. This is achieved by passing the mains

water through a plate heat exchanger. The outlet temperature of the domestic

hot water is maintained by a printed circuit board, which controls the speed of

the pump circulating the primary water from the store through the plate heat

exchanger.

Because of the innovative method of hot water production no in-line scale reducer

is normally required on the cold supply to the appliance.

If scale should become a problem the plate heat exchanger is easily isolated and

replaced with a service exchange unit

1.0 DESIGN

Description

1.1 INTRODUCTION

The pcb also incorporates the facility to operate

the heating pump for a few seconds every few

days when the heating is not being used, to

reduce the likelihood of the pumps sticking

as well as providing a boiler pump overrun

facility.

Any automatic boiler designed to operate

on an 82

0

C flow and a 71

0

C return up to

a

maximum of 35kW can be linked to any

suitable model of BoilerMate 2000 and the

deciding factor is the space heating and the

hot water requirements of a dwelling. See

Section 1.2 Technical Data for further details.

The BoilerMate 2000 is available with the

option of ‘Switch’ which will provide a 9kW

electrical emergency backup in case of failure

of the main heat source. See section 1.3 System

Details for further information.

Gledhill are part of the ‘Benchmark’ scheme

and a separate commissioning/service log

book is included with the product.

������

��� ����

���� ���� ��������� ������ ����� ��� ��������

������ ��� ������� ������ ������������

���������� ������������ ������� ������ ����

������� �� ��� ��������� �� � ���� ���� �������

������� ����

�������

������

��

����

������

����������������

����

���� ����

����� ����

�����

���� ����

Summary of Contents for Gledhill BoilerMate 2000 125

Page 8: ...Page 8 1 0 DESIGN 1 2 TECHNICAL DATA...

Page 33: ...Page 33 BOILERMATE 2000 3 0 SERVICING...

Page 42: ......

Page 43: ......

Page 44: ......