Page 6

Page 7

BOILERMA

TE

2000

1.2 TECHNICAL DATA

Standard Equipment

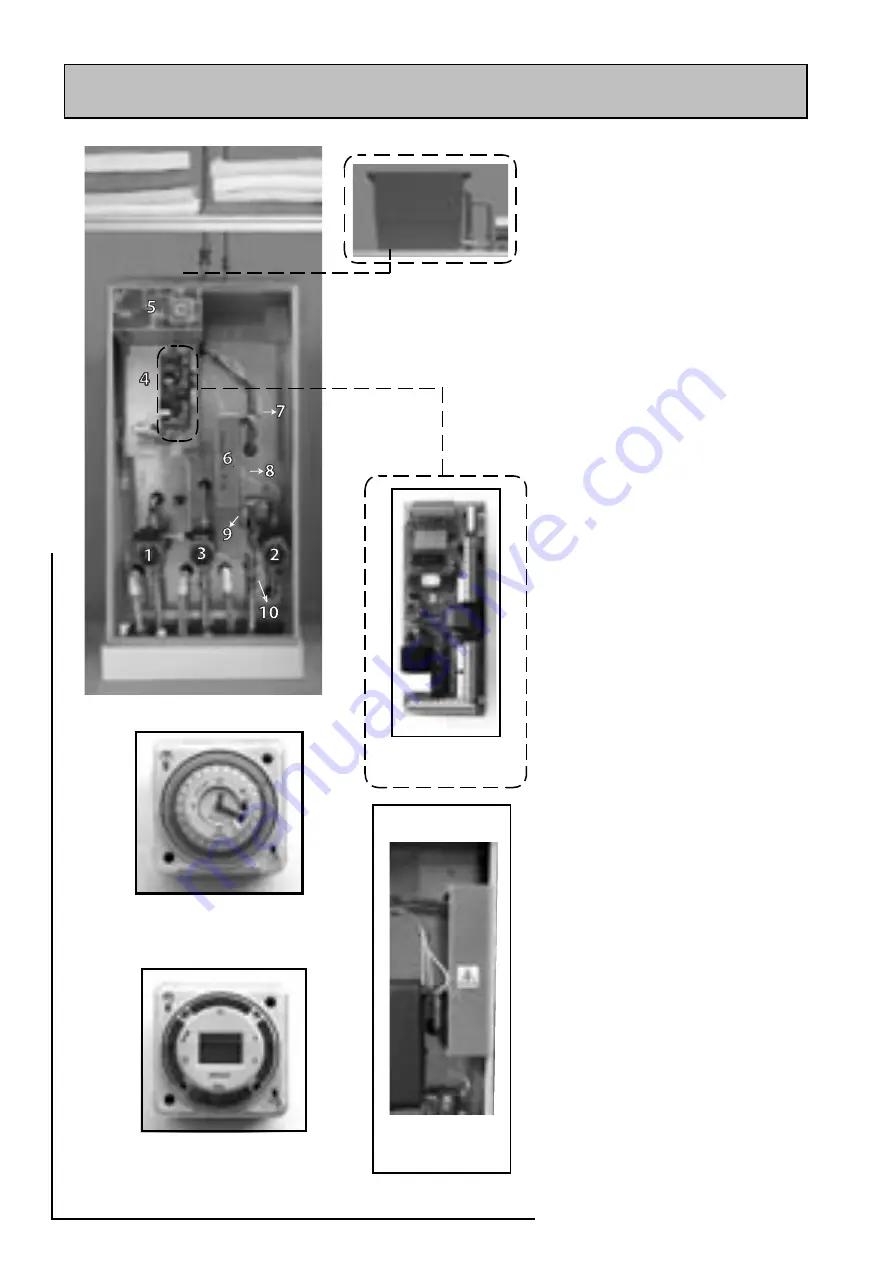

The standard configuration of the BoilerMate

2000 is shown opposite. The Appliance Control

Board (A.C.B.), mounted inside the appliance,

controls the operation of the complete system.

The A.C.B. is pre-wired to a terminal strip

where all electrical connections terminate. It

is supplied with the following factory fitted

equipment:-

1. Boiler pump

2. Domestic hot water primary

(plate heat exchanger) pump

3. Space heating pump

4. Hard water appliance control board

(A.C.B.)

5. Electro-mechanical clock to control the

space heating (in conjunction with room

thermostat - if fitted)

6. Plate heat exchanger

7. DHWS temperature sensor

8. PHE return sensor

9. Store temperature sensor

10. Y type strainer/flow regulator

11. A feed and expansion cistern

complete with ballvalve, overflow

fitting and cold feed/open vent pipework

assembly is supplied separately.

Optional Equipment

* A soft water model is available for areas

where the hardness level is below 200

p.p.m. (mg/ltr)

* Flexible connectors for quick

connection to first fix pipe installation.

For further details see 2.2 Installation,

Pipework connections.

* ‘Switch’ emergency electrical back-up

for heating and hot water in the event

of a boiler fault.

* A seven day digital clock/programmer

to control the space heating (in

conjunction with a room thermostat if

fitted).

* A kit to site the clock/programmer

remotely.

* A no clock option - because of the

design of the appliance it should not be

necessary to fit anything other than a

single channel clock to control the

heating system.

* Hot and cold water manifolds for use with

plastic pipework.

1.0 DESIGN

Appliance Control Board

A.C.B.

Electro-mechanical clock

programmer

Digital clock programmer

‘Switch’

Summary of Contents for Gledhill BoilerMate 2000 125

Page 8: ...Page 8 1 0 DESIGN 1 2 TECHNICAL DATA...

Page 33: ...Page 33 BOILERMATE 2000 3 0 SERVICING...

Page 42: ......

Page 43: ......

Page 44: ......