Device overview

21

iso1685FR(M)_D00002_02_M_XXEN/06.2017

4.3 Display and operating elements

4.3.1 Operating elements

The representation below shows the position of the operating elements

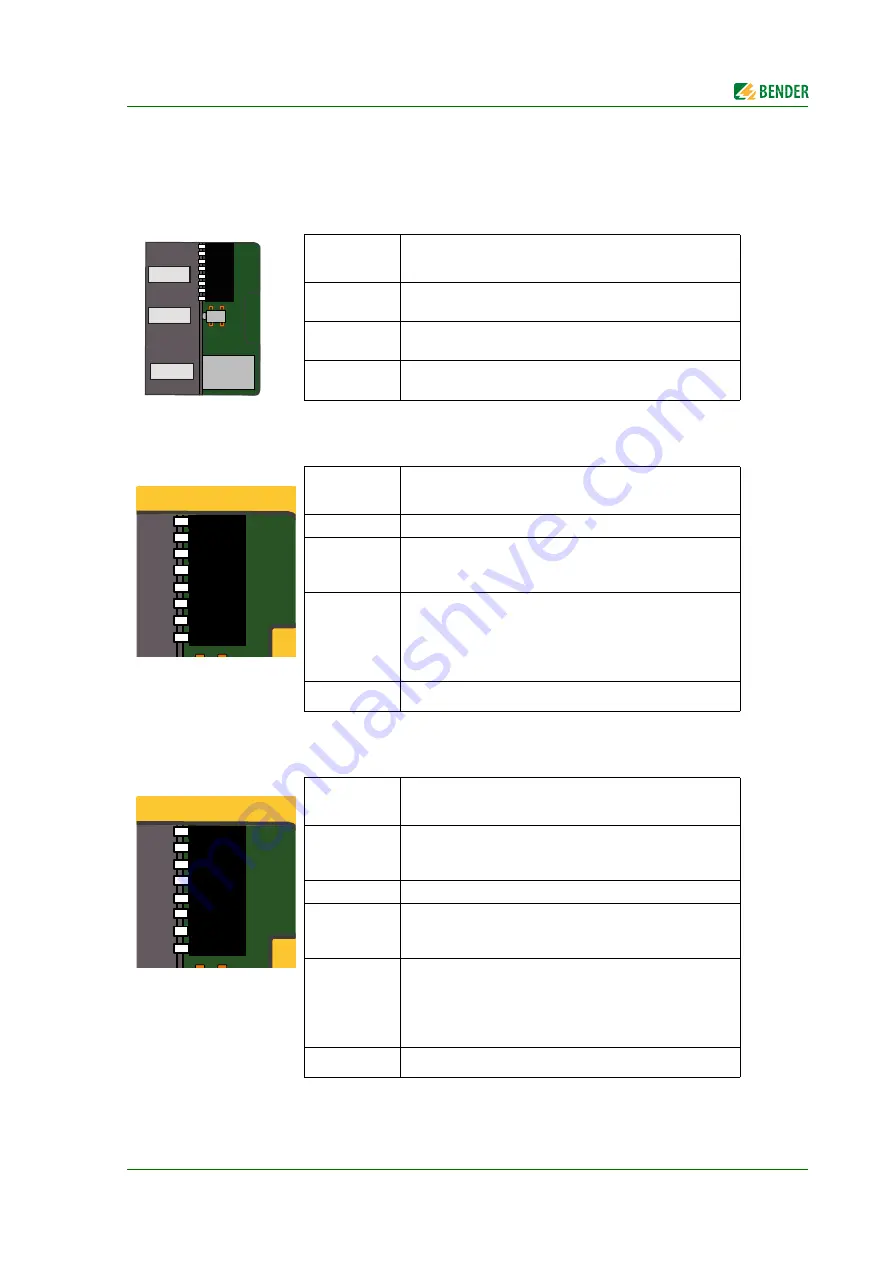

ISOMETER®s iso1685FR DIP swich assignment

ISOMETER®s iso1685FRM DIP switch assignment

Operating

elements

Function

DIP switch

(SS8103)

Setting the BMS address

Button

(ST6101)

Reset device fault messages

Memory card

(SD Card)

Memory for log files and history memory (μSD card);

DIP switch

number

Function

1…5

Setting the BMS address

6

Locking the parameter function

ON = Parameter

cannot

be changed

OFF = Parameter can be changed

7

Device error notification when the μSD card has not been

inserted

ON = Device error will be signalled.

The device-error relay K3 (31/32/34) does

not

switch!

OFF = Device error will

NOT

be signalled.

8

Not used

DIP switch

number

Function

1

Switching between BMS/Modbus RTU protocols

ON = Modbus RTU

OFF = BMS

2…5

Setting BMS address

6

Locking the parameter function

ON = Parameter

cannot

be changed

OFF = Parameter can be changed

7

Device error notification when the μSD card has not been

inserted

ON = Device error will be signalled.

The device-error relay K3 (31/32/34) does

not

switch!

OFF = Device error will

NOT

be signalled.

8

Not used

µSDCard

SS8103

1

2

3

4

5

6

7

8

A4

A3

A2

A1

A0

ST6101

A4

A3

A2

A1

A0

1

2

3

4

5

6

7

8

A4

A3

A2

A1

A0

1

2

3

4

5

6

7

8

Summary of Contents for ISOMETER iso1685FR

Page 6: ...6 ...

Page 10: ...Important information 10 iso1685FR M _D00002_02_M_XXEN 06 2017 ...

Page 14: ...Safety instructions 14 iso1685FR M _D00002_02_M_XXEN 06 2017 ...

Page 42: ...Diagram for the calculation of Ze 42 iso1685FR M _D00002_02_M_XXEN 06 2017 ...

Page 44: ...Information about the measuring method 44 iso1685FR M _D00002_02_M_XXEN 06 2017 ...

Page 50: ...INDEX 50 iso1685FR M _D00002_02_M_XXEN 06 2017 ...

Page 51: ...INDEX 51 iso1685FR M _D00002_02_M_XXEN 06 2017 ...