17

RCMB423_D00241_01_M_XXEN/12.2016

4. Installation and connection

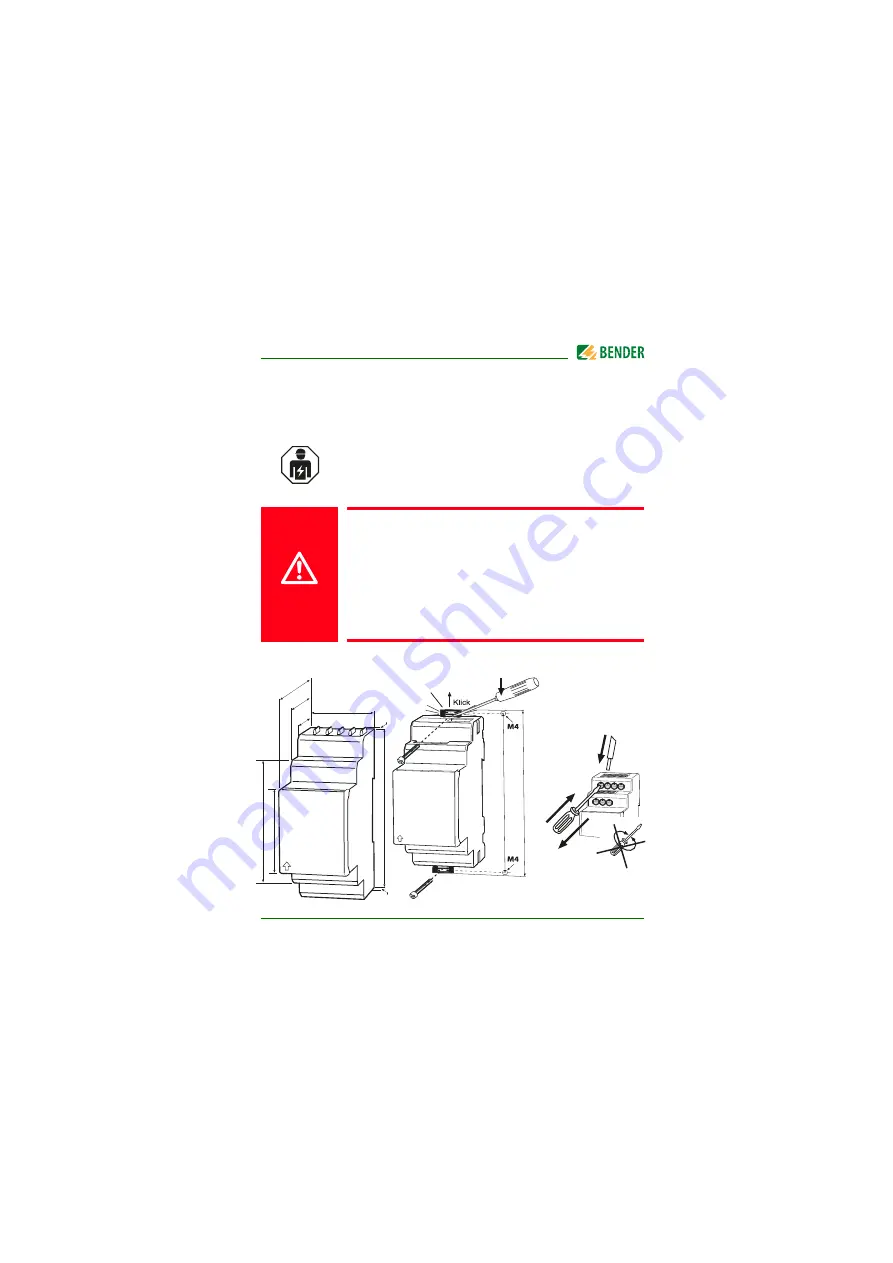

Dimension diagram, drawing for screw fixing, push-wire terminal

Only

qualified personnel

are permitted to carry out the

work necessary to install, commission and run a device or

system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device

,

make sure

that the

installation

has been

de-energised

. Observe the

rules for working on electrical installations.

DANGER

90 mm

45

67,5

36 mm

31,1

47,5

70,5

2

2

100 mm

116 mm

Zubehör/

Accessory

1

2

3