4

AIR INDUCTION

The Bendix

®

360cc Single Cylinder Compressors is

only permitted to be naturally aspirated – use of engine

turbocharger as an air source is not permitted.

PREVENTATIVE MAINTENANCE

Regularly scheduled maintenance is the single most

important factor in maintaining the air brake charging

system.

Refer to Table A: Maintenance Schedule and

Usage Guidelines in the troubleshooting section (page

A-3) for a guide to various considerations that must be

given to maintenance of the compressor and other related

charging system components.

Important Note:

Review the Bendix

®

Warranty Policy

before performing any intrusive maintenance procedures.

An extended warranty may be voided if intrusive

maintenance is performed during this period.

EVERY 6 MONTHS, 1800 OPERATING HOURS

OR AFTER EACH 50,000 MILES WHICHEVER

OCCURS FIRST, PERFORM THE FOLLOWING

INSPECTIONS AND TESTS.

AIR INDUCTION

A supply of clean air is one of the single most important

factors in compressor preventive maintenance. Since the

air supply for Bendix

®

360cc Single Cylinder Compressor

and engine is the engine air cleaner, periodic maintenance

of the engine air fi lter is necessary.

Inspect the compressor air induction system each time

engine air cleaner maintenance is performed.

1. Inspect the intake hose adapters for physical damage.

Make certain to check the adapters at both ends of the

intake hose or tubing.

2. Inspect the intake hose clamps and tighten them if

needed.

3. Inspect the intake hose or line for signs of drying, cracking,

chafi ng and ruptures and replace if necessary.

4. Inspect the compressor’s cast inlet tube for physical

damage.

COMPRESSOR COOLING

Inspect the compressor discharge port, inlet cavity and

discharge line for evidence of restrictions and carbon

buildup. If more than 1/16" of carbon is found, thoroughly

clean or replace the affected parts. In some cases, carbon

buildup indicates inadequate cooling. Closely inspect the

compressor cooling system. Check all compressor coolant

lines for kinks and restrictions to fl ow. Minimum coolant line

size is 3/8" I.D. Check coolant lines for internal clogging

from rust scale. If coolant lines appear suspicious, check

the coolant fl ow and compare to the tabulated technical

data present in the back of this manual.

LUBRICATION

The compressor utilizes an internal oil feed design. Check

the exterior of the compressor (i.e. around the mounting

face) for the presence of oil seepage and refer to the

troubleshooting section for appropriate tests and corrective

action. Refer to the tabulated technical data in the back of

this manual for oil pressure minimum values.

OIL PASSING

All reciprocating compressors pass a minimal amount of

oil. Air dyers will remove the majority of oil before it can

enter the air brake system. For particularly oil sensitive

systems, the Bendix

®

PuraGuard

®

system can be used in

conjunction with a Bendix

®

air dryer.

If compressor oil passing is suspected,

refer to the

Troubleshooting section (starting on page A-1)

for the

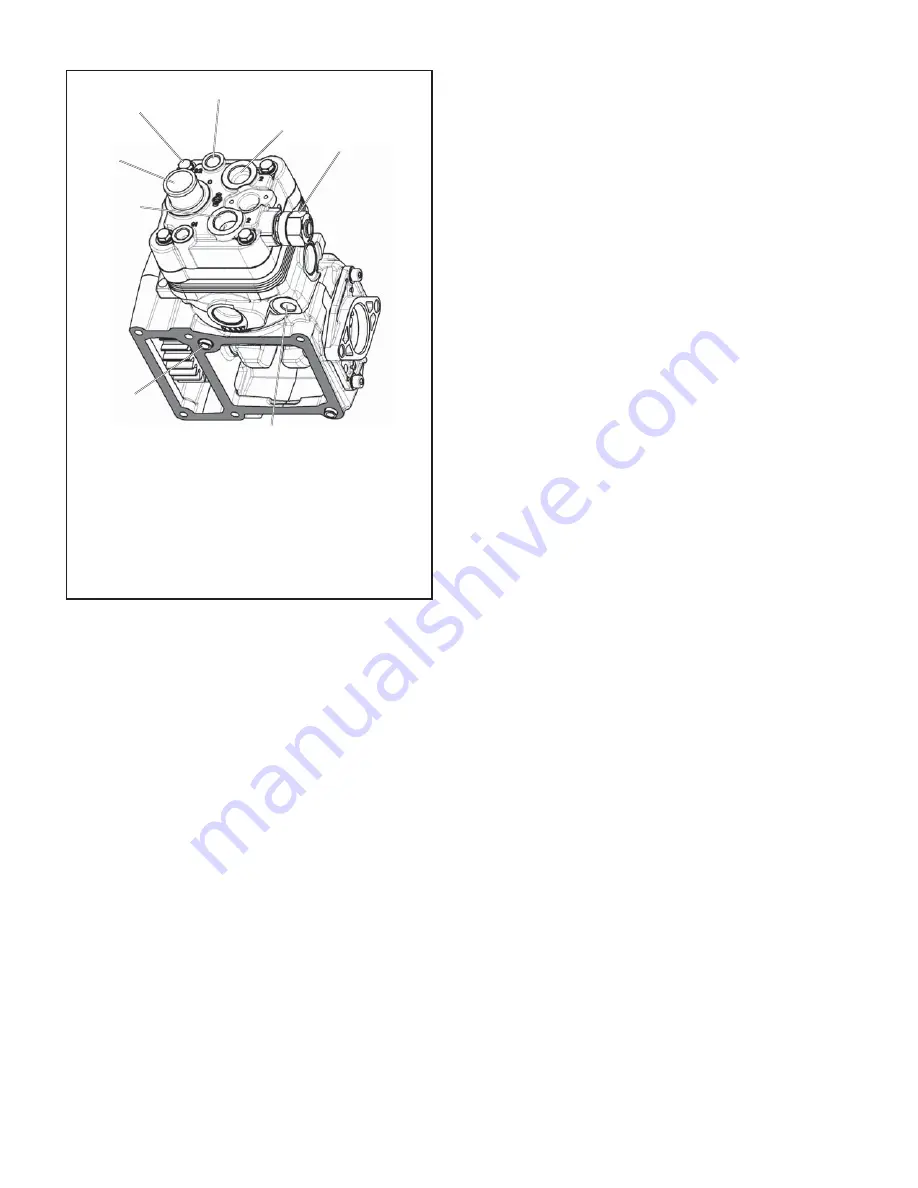

FIGURE 7 - BENDIX

®

360cc SINGLE CYLINDER

COMPRESSOR PORT IDENTIFICATION

Discharge

Port or

Safety

Valve

Port

Inlet

Port

Oil Supply

Head

Bolt (4)

CYLINDER HEAD PORT IDENTIFICATION

The cylinder head connection ports are identifi ed

with “cast in” numerals as follows:

AIR IN . . . . . . . . . . . . . 0

Compressed AIR OUT . . . . . 2

Coolant IN . . . . Crankcase Port

Coolant Out . . . . . . . . . .92

Coolant Out Only

Discharge

Port or Safety

Valve

Port

Port Closed

Coolant In Only

Summary of Contents for 360CC

Page 12: ...12 Notes...